Mechanical Couplings

The most professional manufacturer

EVER-POWER GROUP CO., LTD. IS SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, PARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACCUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS’ DRAWINGS.

WE HAVE EXPORTED OUR PRODUCTS TO CLIENTS AROUND THE WORLD AND EARNED A GOOD REPUTATION BECAUSE OF OUR SUPERIOR PRODUCT QUALITY AND AFTER-SALES SERVICE. WE WARMLY WELCOME CUSTOMERS BOTH AT HOME AND ABROAD TO CONTACT US TO NEGOTIATE BUSINESS, EXCHANGE INFORMATION AND COOPERATE WITH US.

FOR MORE DETAILS, PLEASE CHECK OUT OUR PRODUCTS CATALOGS AND MACHINE LISTS.

WE STAFF OVER 1500 WORKERS, AND HAVE CNC TURNING MACHINES AND CNC WORK CENTERS.

WE ARE ONE OF THE BEST MANUFACTURER AND SUPPLIER IN CHINA, CHOOSE QUALITY MANUFACTURERS, SUPPLIERS, EXPORTERS AT EVER-POWER.NET

Our Product

This new flexible coupling from EP combines the best features of the well-known UNIFLEX and BULLFLEX models at a lower price.

The Combiflex coupling has been designed to ensure optimal damping of torsional vibrations, created by cycle irregularities especially at low revs.

The flexible rubber element ensures low-noise and vibration-free transmission, without backlash between the engine and the propeller shaft.

The Combiflex coupling is secured against shearing off, both axially and radially, thus ensuring safe transmission under all circumstances.

The Combiflex coupling also provides excellent alignment of the propeller shaft.

Perfect alignment of engine and propeller shaft can be a rather time consuming affair, but the Combiflex comes to the aid of the installation engineer.

Even with a misalignment of 2 degrees, the shaft will remain perfectly centred onto the gearbox flange.

The parallel clamping hub ensures easy installation and probably even more importantly, easy dismantling of the shaftassembly.

A flexible coupling provides a flexible connection between the shaft and gearbox. This will reduce noise and vibration on board and is damping torsional vibrations.Blokflex couplings

Blokflex flexible couplings are manufactured according to our high quality standards. Loads can be transferred from different directions (both radially and axially). The flexible couplings are capable to transmit the propeller thrust to the gearbox. The construction of the coupling is fail-safe and ensures a long service life.

In case of the smaller coupling sizes (type 115-4 and 150-4), the aluminum housing is machined fit to the gearbox flange. The standard version comes with a straight bore and keyway. Larger types (160-6 and bigger) are using a separate steel adapter flange (spacer). This adapter is available for e.g. ZF/ Hurth/Velvet, PRM and Paragon gearboxes. Standard type 160-6 and bigger couplings come with a taper bore (1:10) and keyway.

Shaft Couplings Clamps to give a better fit than a solid coupling. Produced by high quality steel. Able to accommodate normal shaft tolerances. Available in standard sizes (Both Metric and Imperial). Easy to install and position. Baysan Marine has developed a comprehensive range of Steel Clamp Half Couplings with flange sizes from 4 to 6 inch diameter. Steel Clamp Half Couplings can accommodate the variations that occur with normal shaft tolerances, are easy to install and can be adjusted to the required position on the shaft. Capacity to machine Split Half Couplings to special sizes.

Torque Limiters

Torque-limiting couplings are used to protect rotating equipment in the event of a jam or stoppage. Past a certain level of torque applied by the load, the coupling disengages so that the load does not apply torsional strain to the drive shaft. Torque limiters are particularly useful in the case of high-value equipment such as large motors, drives, and gearboxes. Preventing catastrophic failure also helps guard against extensive repairs and downtime.

Rubber Couplings

Rubber couplings consist of a rubber spacer sandwiched between two hubs. The rubber does a good job of absorbing shock and vibration, as well as misalignment. Rubber couplings can be designed specifically to compensate for compression or shear force. They also introduce torsional softness. As a result, they can be effective at protecting bearings.

Jaw Couplings

Jaw couplings consist of two opposing hubs formed of two or more arms (jaws) separated by a plastic device known as a spider. They are designed to transmit torque up to a set threshold. Exceeding the tensile strength of the spider causes it to fail, frequently damaging the jaws at the same time. The spider tends to damp vibration. It can also absorb axial extension and compression. With careful design and choice of spider, these couplings can be virtually backlash free. They are also electrically isolating. On the downside, they can only tolerate 0.5 deg or so of angular misalignment and very little parallel misalignment.

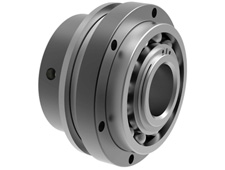

Gear Couplings

Gear couplings are designed to handle extremely high torques. A gear coupling consists of a forged sleeve with internal gears and a pair of shafts terminating in hubs with external gearing. The shafts/hubs are inserted into the sleeve from opposite directions; turning one hub rotates the other. The high surface contact area enables gear couplings to manage extreme torque loads. Like any gearbox, they need lubrication. They also suffer from backlash that varies according to tooth shape and misalignment. If designed with a tight fit between the inner gear and outer gear, gear couplings can be effective at speeds as high as 30,000 to 40,000 RPM.

Disk Couplings

Disk couplings incorporate thin metal disks that act as springs to accommodate flexing and misalignment. These couplings offer high torsional rigidity and minimal backlash. They have the ability to accommodate torques on the level of a bellows coupling but at a lower cost. Disk couplings can handle high speeds. The disk material provides another degree of freedom to optimize system performance. Stainless steel disks work well for medical devices, for example, while nonmetallic disks provide electrical insulation. Aluminum disks and hubs help reduce weight.

Bellows Couplings

As the name suggests, a bellows coupling is built around a metal bellows. These couplings deliver maximum torsional stiffness and flexibility but remain lightweight, minimizing inertia. They are good for applications that need to transfer high torque with minimum backlash.

Bellows couplings perform well at speeds of up to 10,000 RPM. The material used for the bellows depends upon the application. Steel designs deliver maximum torque per diameter. Nickel versions provide better accuracy but they are more fragile and must be used with lower torques.

Beam Couplings

A beam coupling consists of a cylindrical piece of metal, usually aluminum or steel, with one or more spiral cuts sandwiched between solid metal (the beams). The spiral cuts add flexibility but also permit torsional wind up. Beam couplings can handle large amounts of axial and angular misalignment. They are available in single- and multi-beam designs. Multi-beam designs can handle more parallel misalignment than single-beam versions.

The low torsional stiffness of beam couplings increases settling times. These components are best for low-torque applications and those with light loads. They are poor choices for high-speed, high-precision systems.

Visit Us

San Luis Obispo, California, United States

Call Us

(+880) 135 486 7898

Email Us

mechanicalcoupling.com