Mechanical Coupling for Aquarium Systems

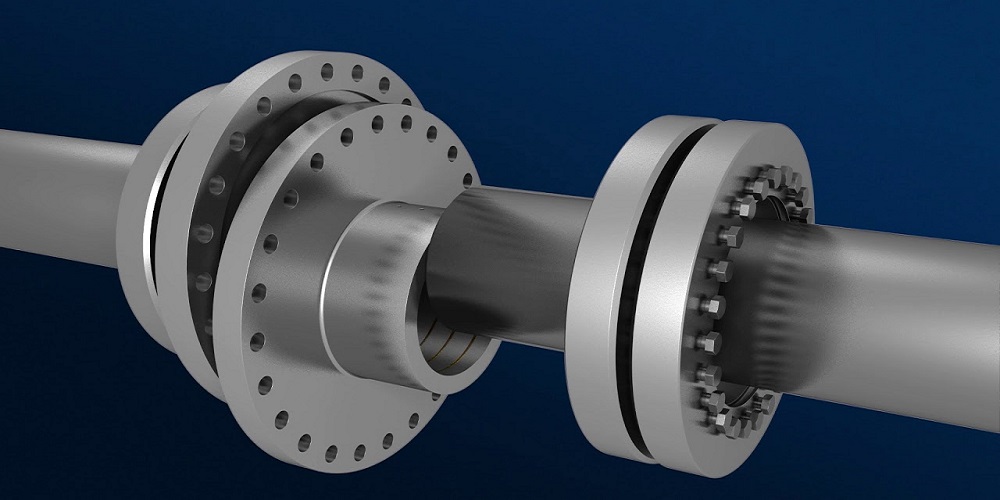

Introduction to Mechanical Couplings

Mechanical couplings play an indispensable role in the operation of aquarium systems. These devices are pivotal in ensuring the seamless transfer of mechanical power, thereby optimizing the functionality of the equipment within the system.

Purpose of Mechanical Couplings in Aquariums

In aquarium systems, mechanical couplings serve to connect shafts and transmit torque while accommodating misalignments. This ensures that the various components of the system operate in harmony, minimizing wear and tear.

Types of Mechanical Couplings

Understanding the different types of mechanical couplings is essential for selecting the appropriate one for your aquarium system. These include rigid couplings, flexible couplings, and fluid couplings, each serving specific operational requirements.

Rigid Couplings

Rigid couplings are employed when precise alignment is necessary. They ensure a solid connection between shafts, making them ideal for applications where misalignment is minimal.

Flexible Couplings

Flexible couplings are designed to accommodate misalignments between connected shafts. They can absorb shock and vibration, making them suitable for dynamic aquarium systems.

Fluid Couplings

Fluid couplings use a hydraulic fluid to transmit torque, providing a smooth and controlled power transfer. They are particularly useful in applications requiring gradual start-ups.

Materials Used in Mechanical Couplings

The choice of material for mechanical couplings is crucial. Materials such as steel, aluminum, and composite materials are commonly used, each offering distinct advantages in terms of strength, durability, and corrosion resistance.

Installation and Maintenance

Proper installation and regular maintenance of mechanical couplings are vital for ensuring their longevity and performance. This includes routine inspections and timely replacements of worn-out components.

Common Issues and Troubleshooting

Despite their robustness, mechanical couplings can encounter issues such as misalignment, excessive vibration, and wear. Identifying and addressing these issues promptly can prevent further damage to the aquarium system.

Advantages of Using Mechanical Couplings in Aquariums

Mechanical couplings offer several benefits, including the ability to handle misalignments, reduce vibrations, and facilitate easy assembly and disassembly of components within the aquarium system.

Applications in Aquarium Systems

Mechanical couplings are used in various applications within aquarium systems, such as connecting pumps, filters, and aeration systems, ensuring efficient and reliable operation.

Choosing the Right Coupling for Your Aquarium

Selecting the appropriate coupling involves considering factors such as the type of misalignment, load capacity, and environmental conditions. Proper selection ensures optimal performance and longevity of the system.

Emerging Trends in Mechanical Couplings

Advancements in technology have led to the development of couplings with enhanced features such as higher torque capacity, improved materials, and smarter designs that cater to the evolving needs of modern aquarium systems.

Environmental Considerations

The impact of mechanical couplings on the environment is an important consideration. Opting for eco-friendly materials and designs can contribute to sustainable aquarium practices.

Future Prospects

The future of mechanical couplings in aquarium systems looks promising with ongoing research and development aimed at enhancing their efficiency, reliability, and environmental compatibility.

Conclusion

Mechanical couplings are integral to the effective operation of aquarium systems. A thorough understanding of their types, applications, and maintenance can significantly enhance the performance and longevity of these systems.

How does a mechanical coupling work?

Mechanical couplings function by connecting two shafts together to transmit power. They compensate for misalignments and mitigate shock loads, ensuring the seamless operation of the connected devices.

How do I choose a mechanical coupling?

Selecting the right mechanical coupling involves considering several parameters and conditions:

- Alignment: Assess the degree of misalignment between the shafts to choose between rigid and flexible couplings.

- Torque Requirements: Determine the torque that needs to be transmitted to select a coupling with adequate capacity.

- Environmental Conditions: Consider factors such as temperature, humidity, and exposure to chemicals that may affect the coupling material.

- Load Characteristics: Evaluate whether the load is steady or fluctuating to choose a coupling that can handle the specific load dynamics.

- Space Constraints: Ensure that the chosen coupling fits within the spatial limitations of the aquarium system setup.

What are the classification of couplings in mechanical engineering?

Mechanical couplings can be classified into several categories based on their design and function:

- Rigid Couplings: These include flange couplings, sleeve couplings, and clamp couplings, used for precise alignment.

- Flexible Couplings: Types include gear couplings, grid couplings, and elastomeric couplings, which accommodate misalignments and absorb shocks.

- Fluid Couplings: Hydraulic couplings and torque converters fall under this category, providing smooth and controlled torque transfer.

- Magnetic Couplings: Utilize magnetic fields to transmit torque without physical contact, ideal for sterile and high-purity applications.

HZPT: Your Trusted Mechanical Coupling Manufacturer

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, production, and international trade. We adhere to our core value of “integrity” as our business philosophy, fostering unity, progress, and innovation. We specialize in coupling products, driving technological advancements and international trade.

Our product range includes drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We pride ourselves on a complete and scientific quality management system, with our technical development and testing department. Our certifications include CQC, ISO, and CE.

We offer excellent sales services and technical support to our clients. With over a hundred cooperative enterprises, we adhere to our people-oriented and customer-first philosophy, working in close cooperation with our clients for mutual development.

Why Choose Our Products?

- High Quality: Our products are manufactured with high-grade materials ensuring durability and reliability.

- Innovative Design: We continuously develop innovative coupling designs that meet the evolving needs of our customers.

- Global Reach: With a presence across Asia, Europe, Africa, and North America, we offer global support and services.

- Comprehensive Support: We provide extensive technical support and after-sales service to ensure customer satisfaction.

- Certified Excellence: Our products are certified by CQC, ISO, and CE, attesting to their quality and performance.