Mechanical Coupling for Asphalt Laying Equipment

The Importance of Mechanical Coupling in Asphalt Laying

Mechanical coupling plays a pivotal role in the optimal functioning of asphalt laying equipment. It ensures seamless power transmission and enhances the overall efficiency of the machinery.

Types of Mechanical Couplings Used in Asphalt Laying

Various types of mechanical couplings are utilized in asphalt laying, each serving a unique purpose. These include rigid couplings, flexible couplings, and torsional couplings.

Rigid Couplings

Rigid couplings are designed to maintain precise alignment between connected shafts. They are ideal for applications where misalignment is minimal.

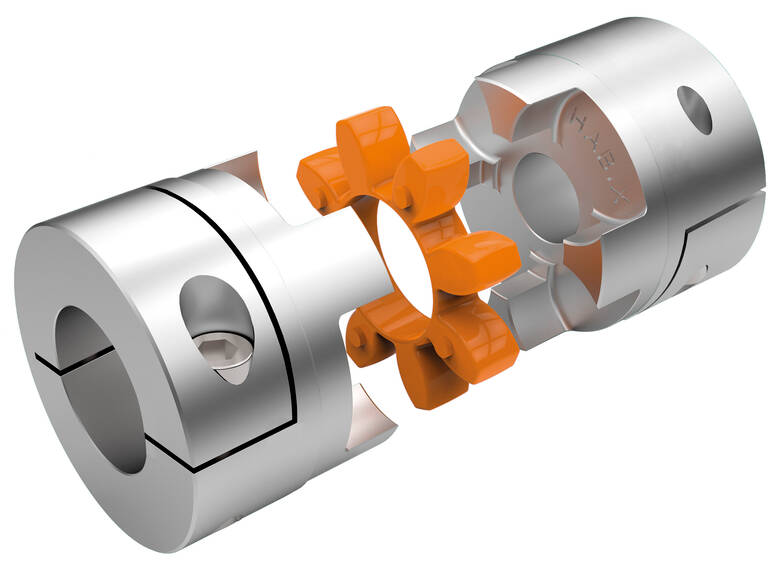

Flexible Couplings

Flexible couplings accommodate slight misalignments and absorb shocks, making them suitable for dynamic applications in asphalt laying.

Torsional Couplings

Torsional couplings are engineered to handle torsional vibrations and fluctuations, ensuring smooth operation of the asphalt laying equipment.

Benefits of Using Mechanical Couplings

Mechanical couplings provide numerous benefits including reduced wear and tear, improved energy efficiency, and enhanced operational stability.

Selection Criteria for Mechanical Couplings

Selecting the right mechanical coupling involves considering factors such as load capacity, alignment tolerance, and operational conditions.

Load Capacity

The load capacity of a coupling should match the operational requirements of the asphalt laying equipment to ensure durability and efficiency.

Alignment Tolerance

Couplings with higher alignment tolerance are preferred for applications where precision is critical, such as in asphalt laying machinery.

Operational Conditions

Operational conditions like temperature, humidity, and environmental contaminants influence the selection of suitable mechanical couplings.

Installation and Maintenance of Couplings

Proper installation and regular maintenance of mechanical couplings are crucial for the longevity and optimal performance of asphalt laying equipment.

Innovations in Mechanical Coupling Technology

Recent advancements in coupling technology have led to the development of high-performance couplings that offer superior flexibility and durability.

Impact of Coupling Failures

Coupling failures can lead to significant operational disruptions and increased maintenance costs, highlighting the importance of using high-quality couplings.

Future Trends in Coupling Design

The future of coupling design is geared towards achieving higher efficiency, greater reliability, and enhanced adaptability to diverse operational conditions.

Conclusion

Mechanical couplings are indispensable components in asphalt laying equipment, ensuring efficient power transmission and operational stability.

How does a mechanical coupling work?

A mechanical coupling functions by connecting two shafts together, allowing for the transmission of power and torque between them. It compensates for slight misalignments and absorbs shocks, ensuring smooth and efficient operation of the machinery.

How do I choose a mechanical coupling?

When selecting a mechanical coupling, consider the following parameters:

- Torque Requirements: Ensure that the coupling can handle the maximum torque generated by the machinery.

- Misalignment Tolerance: Choose a coupling that can accommodate the expected misalignment between connected shafts.

- Operational Speed: The coupling should be suitable for the operational speed of the equipment to prevent vibrations and wear.

- Environmental Conditions: Evaluate the environmental conditions such as temperature, humidity, and exposure to contaminants, and select a coupling that can withstand these factors.

- Maintenance Requirements: Opt for couplings that offer ease of maintenance and long service intervals to minimize downtime.

What are the classification of couplings in mechanical engineering?

In mechanical engineering, couplings are classified into various categories based on their design and function. These include:

- Rigid Couplings: Designed for precise alignment and rigid connection between shafts.

- Flexible Couplings: Accommodate misalignment and absorb shock, reducing wear and tear.

- Fluid Couplings: Use a fluid medium to transmit power, offering smooth and adjustable torque transmission.

- Magnetic Couplings: Utilize magnetic fields to transmit torque without physical contact, ideal for contamination-free environments.

- Universal Joints: Allow for flexible connection between shafts at varying angles, commonly used in automotive applications.

About HZPT

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating research and development, production, learning, and foreign trade. We adhere to the core values of “integrity” as our business philosophy, promoting unity, progress, and innovation. Our company focuses on the research and innovation of coupling products, combining high-tech development, international trade, industrial investment, and a robust domestic and international network.

We specialize in the production of drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, tire couplings, and other coupling series. Our comprehensive and scientific quality management system, along with our dedicated technical development and testing departments, ensures the highest quality standards. We hold certifications such as CQC, ISO, and CE, and provide excellent sales services and technical support to our clients. Serving over a hundred partner enterprises, we uphold the business philosophy of “people-oriented, customer-first,” working in close cooperation with our clients for mutual development.

Why Choose Our Mechanical Couplings?

- High-Quality Manufacturing: Our products are manufactured to the highest standards, ensuring durability and reliability.

- Advanced Technology: We utilize cutting-edge technology in the design and production of our couplings, providing superior performance.

- Comprehensive Quality Management: Our scientific quality management system ensures that every product meets stringent quality criteria.

- Extensive Product Range: We offer a wide variety of coupling products to meet diverse application needs.

- Excellent Customer Service: Our dedicated support team provides exceptional sales and technical assistance to our clients, ensuring their satisfaction.