Mechanical Coupling for ATM Machines

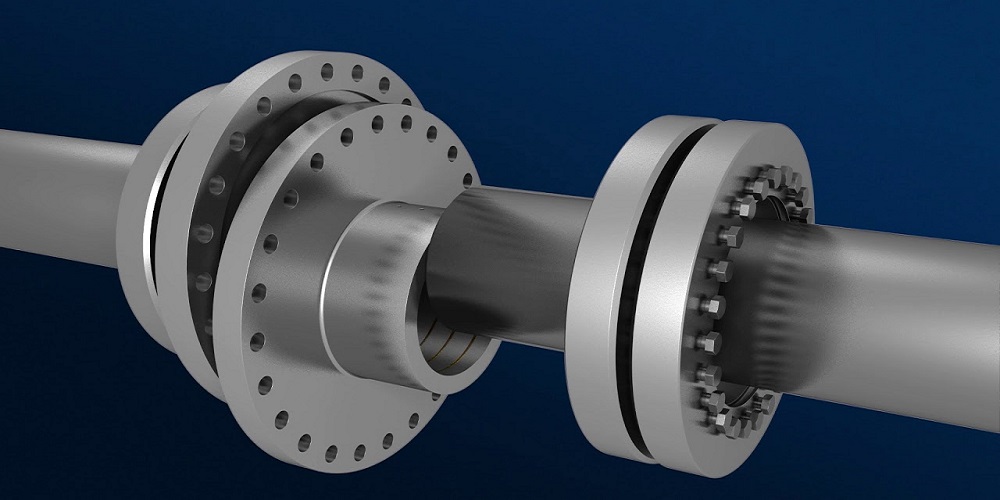

Introduction to Mechanical Coupling

Mechanical coupling is an essential component in the seamless operation of ATM machines. It ensures the efficient transfer of power and torque, allowing various mechanical parts to function cohesively.

The Role of Mechanical Coupling in ATM Machines

In ATM machines, mechanical coupling plays a pivotal role by connecting the motor to other mechanical components. This connection facilitates the synchronized operation required for dispensing cash, printing receipts, and other actions.

Types of Mechanical Couplings

There are several types of mechanical couplings used in ATM machines, including rigid couplings, flexible couplings, and universal joints. Each type offers specific advantages tailored to the operational requirements of ATMs.

Advantages of Using Mechanical Couplings

Mechanical couplings offer numerous benefits, such as reduced wear and tear on connected components, improved alignment, and enhanced operational efficiency. These advantages contribute to the longevity and reliability of ATM machines.

Material Considerations

The materials used in manufacturing mechanical couplings significantly affect their performance. Common materials include steel, aluminum, and various alloys, each selected based on durability, strength, and specific application needs.

Installation and Maintenance

Proper installation and regular maintenance of mechanical couplings are crucial for ensuring their optimal performance. This includes accurate alignment, adequate lubrication, and timely replacement of worn parts.

Common Issues and Troubleshooting

Common issues with mechanical couplings in ATM machines include misalignment, excessive vibration, and wear. Identifying and addressing these problems promptly can prevent further damage and downtime.

Technological Advancements

Recent technological advancements have led to the development of more efficient and durable mechanical couplings. Innovations such as self-aligning couplings and enhanced material compositions are setting new standards in the industry.

Environmental Considerations

Environmental factors such as temperature, humidity, and exposure to contaminants can affect the performance of mechanical couplings. Selecting appropriate materials and designs can mitigate these impacts.

Economic Implications

The cost-effectiveness of mechanical couplings is a significant consideration for ATM machine operators. Investing in high-quality couplings can reduce maintenance costs and extend the lifespan of the machines.

Future Trends

Future trends in mechanical coupling technology include the integration of smart sensors for real-time monitoring and predictive maintenance, further enhancing the reliability and efficiency of ATM machines.

Case Studies

Several case studies have demonstrated the benefits of using advanced mechanical couplings in ATM machines. These studies highlight improvements in performance, reliability, and customer satisfaction.

Customization Options

Customization options for mechanical couplings allow ATM machine manufacturers to tailor the components to specific operational requirements. This customization ensures optimal performance and compatibility.

Regulatory Standards

Compliance with regulatory standards is essential for mechanical couplings used in ATM machines. Adhering to these standards ensures safety, reliability, and legal compliance.

Conclusion

Mechanical couplings are critical components in the operation of ATM machines. Their role in ensuring efficient power transmission and synchronization cannot be overstated. As technology advances, the future of mechanical coupling looks promising, with innovations aimed at further enhancing their performance.

How Does a Mechanical Coupling Work?

A mechanical coupling works by connecting two rotating shafts, allowing them to transmit torque and rotational motion. The coupling accommodates misalignment and reduces vibration, ensuring smooth operation of the connected machinery.

How Do I Choose a Mechanical Coupling?

- Torque Requirements: Ensure the coupling can handle the maximum torque of the system to prevent failure.

- Misalignment Tolerance: Select a coupling that accommodates the expected angular, parallel, and axial misalignment.

- Environmental Conditions: Consider factors like temperature, humidity, and exposure to corrosive substances when choosing materials.

- Speed Capacity: The coupling should be rated for the maximum rotational speed of the application to avoid issues.

- Space Constraints: Ensure the coupling fits within the available space without hindering other components.

What Are the Classification of Couplings in Mechanical Engineering?

Mechanical couplings are classified into various types based on their design and application:

- Rigid Couplings: Provide a solid connection between shafts without accommodating misalignment.

- Flexible Couplings: Allow for some degree of misalignment and absorb shock loads.

- Fluid Couplings: Use hydraulic fluid to transmit torque and provide smooth acceleration and deceleration.

- Universal Joints: Allow for a wide range of motion and are used in applications with complex shaft movements.

- Oldham Couplings: Compensate for misalignment with a sliding motion, ideal for precise applications.

HZPT: Your Trusted Partner in Mechanical Couplings

HZPT, headquartered in Hangzhou, Zhejiang Province, is a modern enterprise specializing in the research, development, production, and international trade of mechanical couplings. Our core values of integrity, unity, progress, and innovation drive our commitment to excellence. We integrate high-tech development, international trade, industrial investment, and domestic and international networks, focusing on the study and innovation of coupling products.

We offer a comprehensive range of couplings, including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. Our complete and scientific quality management system, along with our technical development and testing departments, ensure that our products meet the highest standards.

Why Choose HZPT?

- High-Quality Products: We use superior materials and advanced manufacturing processes to produce durable and reliable couplings.

- Comprehensive Quality Management: Our ISO, CE, and CQC certifications demonstrate our commitment to quality assurance.

- Innovation and Research: Our dedicated R&D team continuously works on developing innovative solutions to meet industry demands.

- Global Reach: Our extensive network spans Asia, Europe, Africa, and North America, ensuring timely delivery and support.

- Customer-Centric Approach: We prioritize our clients’ needs, offering exceptional sales and technical support to foster long-term partnerships.

Partner with HZPT for your mechanical coupling needs and experience the advantages of working with a leader in the industry. Contact us today to learn how we can support your business.