Mechanical Coupling for Banking Equipment

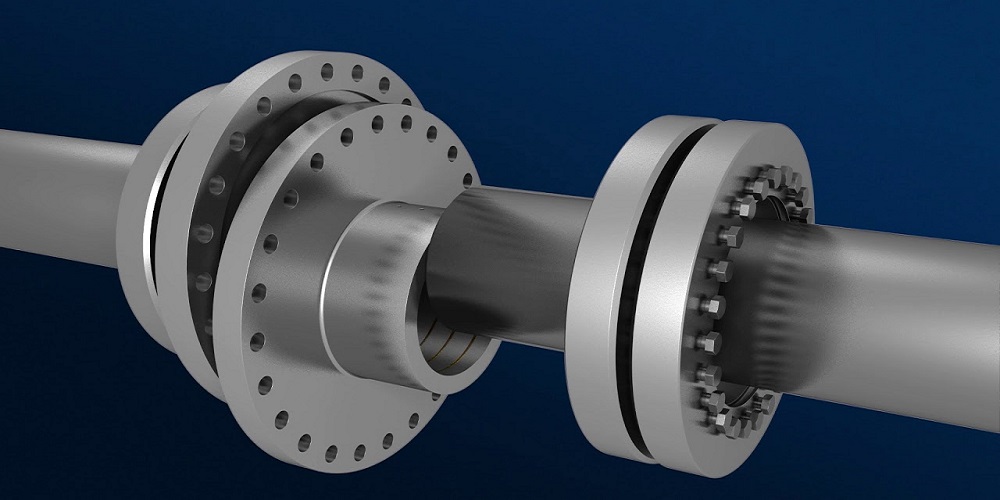

Introduction to Mechanical Coupling

Mechanical coupling is a fundamental component used in various banking equipment to ensure smooth and efficient operation. It connects two shafts together to transmit power and torque, enhancing the equipment’s performance and durability.

Types of Mechanical Couplings

Rigid Couplings

Rigid couplings are designed for precision alignment, making them ideal for applications where shafts are in perfect alignment. They provide a solid connection but do not accommodate any misalignment.

Flexible Couplings

Flexible couplings are used where there is a need to absorb misalignment, vibration, or thermal expansion. They offer versatility and are commonly used in dynamic banking equipment.

Gear Couplings

Gear couplings consist of two hubs with external and internal gears. They provide high torque transmission and are suitable for heavy-duty applications in banking machinery.

Advantages of Using Mechanical Couplings in Banking Equipment

Enhanced Efficiency

Mechanical couplings ensure efficient power transmission, reducing energy losses and enhancing the overall performance of banking equipment.

Improved Durability

By accommodating misalignment and reducing stress, mechanical couplings extend the lifespan of equipment, minimizing the need for frequent maintenance.

Vibration Dampening

Flexible couplings, in particular, help in dampening vibrations, leading to smoother operation and reduced noise in banking environments.

Applications of Mechanical Couplings in Banking Equipment

ATMs

Mechanical couplings are crucial in ATMs for connecting various components, ensuring reliable operation and minimal downtime.

Currency Sorting Machines

In currency sorting machines, mechanical couplings facilitate precise movement and sorting of banknotes, enhancing accuracy and speed.

Cheque Processing Equipment

Couplings ensure seamless power transmission in cheque processing machines, enabling efficient handling and processing of cheques.

Selection Criteria for Mechanical Couplings

Torque Requirements

Understanding the torque requirements of your banking equipment is essential in selecting the appropriate coupling to ensure efficient power transmission.

Misalignment Tolerance

Consider the level of misalignment the coupling needs to accommodate to avoid stress on the equipment and ensure smooth operation.

Environmental Conditions

The operating environment, including temperature and humidity, plays a crucial role in the selection of couplings to ensure longevity and performance.

Maintenance and Care of Mechanical Couplings

Regular Inspections

Conducting regular inspections can help in early detection of wear and tear, preventing potential breakdowns and extending the equipment’s lifespan.

Lubrication

Proper lubrication is essential for reducing friction and wear in mechanical couplings, ensuring smooth and efficient operation.

Alignment Checks

Regular alignment checks are crucial to ensure that the couplings are functioning correctly and to prevent undue stress on connected components.

Conclusion

Mechanical couplings play a vital role in the efficient operation of banking equipment, offering numerous benefits such as enhanced efficiency, improved durability, and reduced vibration. By understanding the different types, applications, and maintenance requirements of mechanical couplings, banking institutions can ensure reliable and smooth operations.

How Does a Mechanical Coupling Work?

Mechanical couplings work by connecting two rotating shafts together, allowing for the transfer of power and torque. They accommodate various degrees of misalignment while ensuring efficient power transmission, making them crucial in many industrial applications.

How Do I Choose a Mechanical Coupling?

Choosing the right mechanical coupling involves considering several key parameters and actual conditions:

- Torque Requirements: Determine the torque requirements to ensure the coupling can handle the load without slipping or failing.

- Misalignment Tolerance: Assess the degree of misalignment the coupling needs to accommodate to prevent stress and wear on the connected components.

- Environmental Conditions: Consider factors such as temperature, humidity, and exposure to chemicals that could affect the coupling’s performance and longevity.

- Speed of Operation: Evaluate the operating speed of the equipment to select a coupling that can handle high-speed rotations without excessive wear.

- Maintenance Requirements: Choose a coupling that aligns with the maintenance capabilities and schedule of your facility to ensure long-term reliability.

What Are the Classification of Couplings in Mechanical Engineering?

Couplings in mechanical engineering can be classified into various types based on their design and function:

- Rigid Couplings: Provide a solid connection and are used where precise alignment of shafts is possible.

- Flexible Couplings: Accommodate misalignment and absorb vibration, suitable for dynamic applications.

- Fluid Couplings: Use hydraulic fluid to transmit torque, offering smooth and controlled power transmission.

- Magnetic Couplings: Utilize magnetic fields to transfer torque without direct contact, ideal for sealed systems.

- Disc Couplings: Consist of a series of thin, flexible discs that can handle high torque and misalignment.

HZPT: Your Trusted Mechanical Coupling Partner

HZPT, based in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, production, and international trade. We adhere to our core values of “integrity,” fostering unity, progress, and innovation. We specialize in the research and innovation of coupling products, with a business presence across Asia, Europe, Africa, and North America, striving to become a globally influential international group.

Our company specializes in producing a wide range of couplings, including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system, along with our own technology development and testing department. We possess certifications such as CQC, ISO, and CE, ensuring top-quality products and services.

Here are five advantages of working with us:

- Extensive Product Range: We offer a comprehensive selection of coupling products, catering to various industrial needs and applications.

- Quality Assurance: Our products undergo rigorous testing and quality control, ensuring reliability and longevity.

- Innovative Solutions: We are committed to continuous R&D, providing innovative and customized solutions for our clients.

- Global Reach: With a presence in multiple continents, we offer prompt and efficient service to our international clients.

- Customer-Centric Approach: We prioritize our customers’ needs, offering excellent sales support and technical assistance to ensure satisfaction and success.