Mechanical Coupling for Beer Bottling Lines

Introduction to Mechanical Couplings in Beer Bottling

The beer bottling industry relies heavily on mechanical couplings to ensure efficiency and precision in the bottling process. These components play a crucial role in maintaining the integrity of the production line.

The Role of Mechanical Couplings in Production Lines

Mechanical couplings connect different parts of a bottling line, ensuring smooth and synchronized operation. They transmit torque and accommodate misalignment, making them indispensable for high-speed production.

Types of Mechanical Couplings Used in Beer Bottling

Various types of couplings are used in beer bottling lines, each tailored to specific requirements such as torque transmission, alignment, and environmental conditions.

Rigid Couplings

Rigid couplings are used where precise alignment is necessary. They are ideal for applications where there is no need for flexibility or adjustment once the machinery is aligned.

Flexible Couplings

Flexible couplings can accommodate misalignment and absorb shock loads. They are essential in applications where machinery components may not be perfectly aligned.

Gear Couplings

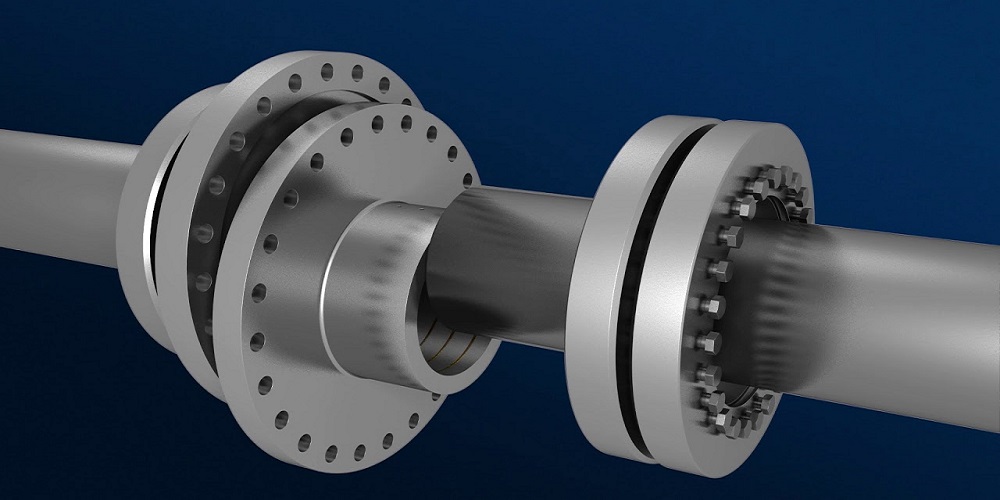

Gear couplings are designed to handle high torque applications. They consist of two hubs with external teeth and a sleeve with internal teeth, providing robust torque transmission.

Disc Couplings

Disc couplings utilize a series of flexible discs to transmit torque while accommodating misalignment. They are known for their high torsional stiffness and low backlash.

Safety and Efficiency in Bottling Lines

Using the appropriate mechanical coupling ensures the safety and efficiency of the bottling line, reducing downtime and maintenance costs.

Maintenance and Longevity of Mechanical Couplings

Regular maintenance is crucial for the longevity of mechanical couplings. Proper lubrication and periodic inspections can prevent unexpected failures.

Innovations in Mechanical Coupling Technology

Recent innovations have led to the development of more durable and efficient couplings, incorporating advanced materials and engineering techniques.

Cost-Effectiveness of Mechanical Couplings

While the initial investment in high-quality couplings may be significant, the long-term benefits in terms of reduced maintenance and downtime make them cost-effective.

Environmental Considerations

Selecting the right coupling can also have environmental benefits, such as reduced energy consumption and lower greenhouse gas emissions.

Case Study: Successful Implementation in a Brewery

A leading brewery successfully implemented advanced mechanical couplings in their bottling line, resulting in a 20% increase in efficiency and a significant reduction in maintenance costs.

Choosing the Right Mechanical Coupling

Selecting the right mechanical coupling for your bottling line requires consideration of several factors, including torque requirements, alignment, and environmental conditions.

Future Trends in Mechanical Coupling Technology

The future of mechanical couplings in the beer bottling industry looks promising, with ongoing advancements aimed at further enhancing efficiency and reliability.

How Does a Mechanical Coupling Work?

Mechanical couplings work by connecting two shafts together, allowing them to rotate as a single unit while transmitting torque and accommodating some degree of misalignment. The design of the coupling determines its ability to handle various types of loads and misalignments.

How Do I Choose a Mechanical Coupling?

Choosing the right mechanical coupling involves considering several parameters:

- Torque Requirements: Determine the maximum torque that the coupling needs to transmit. This is critical for ensuring the coupling can handle the load without failure.

- Alignment: Assess the degree of misalignment between the shafts. Some couplings are better suited for handling angular, parallel, or axial misalignment.

- Environmental Conditions: Consider the operating environment, including temperature, humidity, and exposure to chemicals. This impacts the material selection and design of the coupling.

- Speed: The rotational speed of the shafts influences the type of coupling required. High-speed applications may need couplings with low backlash and high precision.

- Maintenance: Evaluate the maintenance requirements and durability of the coupling. Some couplings are designed for low maintenance, which can be beneficial in reducing downtime.

What are the Classification of Couplings in Mechanical Engineering?

Mechanical couplings can be broadly classified into several categories based on their design and function:

- Rigid Couplings: These couplings provide a solid connection between two shafts without allowing for misalignment or movement. They are typically used in applications where precise alignment is required.

- Flexible Couplings: Flexible couplings can accommodate misalignment and absorb shock loads. They are suitable for applications where some degree of flexibility is needed.

- Fluid Couplings: These couplings use a fluid medium to transmit torque, providing smooth and controlled power transmission. They are often used in applications requiring variable speed control.

- Magnetic Couplings: Magnetic couplings transfer torque through a magnetic field, allowing for a non-contact connection between shafts. This is useful in applications where contamination or leakage needs to be prevented.

- Universal Joints: Also known as U-joints, these couplings allow for significant angular misalignment between shafts, making them ideal for applications requiring flexible power transmission.

About HZPT

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating research and development, learning, production, and foreign trade. We adhere to the core values of the company and operate with integrity, unity, progress, and innovation. Our company focuses on the research and innovation of coupling products, combining high-tech development, international trade, industrial investment, and domestic and international networks.

Our business spans Asia, Europe, Africa, and North America, moving towards the vision of becoming a globally influential international group. We specialize in producing a series of coupling products, including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, locking couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system, and our own technical development and testing departments with CQC, ISO, and CE certificates. We provide excellent sales service and technical support to hundreds of cooperative enterprises, adhering to the business philosophy of ‘people-oriented, customer first,’ working with customers to achieve mutual development.

Why Choose Our Mechanical Couplings?

- Advanced Technology: Our couplings are designed using the latest technology, ensuring high performance and reliability in demanding applications.

- Quality Assurance: We have a comprehensive quality management system and hold multiple certifications, including CQC, ISO, and CE, ensuring the highest standards.

- Wide Range of Products: We offer a diverse range of coupling products, catering to various industrial needs and applications.

- Global Reach: Our business operations span multiple continents, providing our products to customers worldwide with efficient logistics and support.

- Customer-Centric Approach: We prioritize our customers’ needs, offering tailored solutions and excellent after-sales service to ensure satisfaction.