Mechanical Coupling for Boarding Kennels Equipment

Introduction to Mechanical Coupling

Mechanical coupling plays a pivotal role in ensuring the seamless operation of boarding kennel equipment. It is essential to understand the intricate details and functionalities of these couplings to maintain optimal performance.

What is Mechanical Coupling?

Mechanical coupling refers to the device used to connect two shafts together at their ends for the purpose of transmitting power. Couplings do not normally allow disconnection of shafts during operation but can slip or fail when some torque limit is exceeded.

Importance in Boarding Kennels

In the context of boarding kennels, mechanical couplings ensure that equipment such as feeding systems, cleaning mechanisms, and ventilation units work efficiently by maintaining synchronization and power transmission.

Types of Mechanical Couplings

Understanding the different types of mechanical couplings can help in selecting the right one for specific applications in boarding kennels.

Rigid Couplings

Rigid couplings are used when precise alignment of shafts is required. They offer high torque transmission but can transmit vibrations.

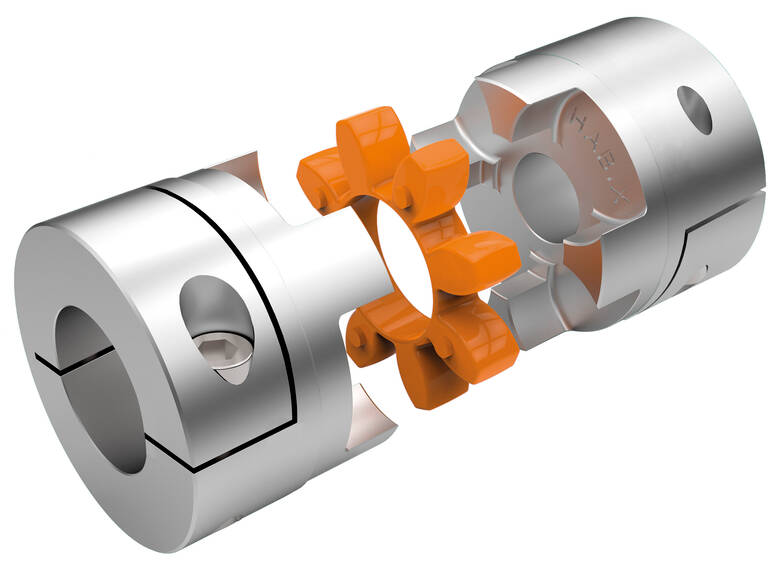

Flexible Couplings

Flexible couplings can accommodate misalignment between shafts. They are ideal in environments where slight deviations are expected.

Gear Couplings

Gear couplings consist of two hubs with external teeth and a sleeve with internal teeth. They provide high torque capacity and can accommodate angular misalignment.

Fluid Couplings

Fluid couplings use hydraulic fluid to transmit torque, providing smooth acceleration and reducing shock loads.

Advantages of Using Mechanical Couplings

Mechanical couplings offer several advantages, including increased efficiency, reliability, and ease of maintenance.

Efficiency

By ensuring seamless power transmission, mechanical couplings enhance the overall efficiency of boarding kennel equipment.

Reliability

Mechanical couplings are designed to be durable and dependable, reducing the risk of equipment failure and downtime.

Ease of Maintenance

Many mechanical couplings are designed for easy installation and maintenance, minimizing the need for extensive downtime during servicing.

Installation Considerations

Proper installation of mechanical couplings is critical to ensure their optimal performance. Factors such as alignment and tightening torque should be carefully monitored.

Common Issues and Troubleshooting

Understanding common issues that can arise with mechanical couplings, such as misalignment and wear, is essential for effective troubleshooting and maintenance.

Maintenance Best Practices

Regular inspection and maintenance are key to prolonging the lifespan of mechanical couplings. This includes monitoring for signs of wear and ensuring proper lubrication.

Future Trends in Mechanical Coupling Technology

Advancements in materials and design are driving the development of next-generation mechanical couplings that offer even greater performance and reliability.

Conclusion

The critical role of mechanical couplings in boarding kennels cannot be overstated. By ensuring reliable and efficient power transmission, they contribute significantly to the smooth operation of various equipment.

How Does a Mechanical Coupling Work?

Mechanical couplings work by connecting two rotating shafts together, allowing them to transmit power and motion. The coupling accommodates slight misalignments and variations in torque, ensuring smooth operation.

How Do I Choose a Mechanical Coupling?

Choosing the right mechanical coupling involves considering several parameters and actual conditions:

- Torque Requirements: Determine the torque that needs to be transmitted to ensure the coupling can handle the load.

- Misalignment Tolerance: Consider the degree of misalignment the coupling can accommodate, including angular, parallel, and axial misalignment.

- Environmental Conditions: Evaluate the working environment, including temperature, humidity, and exposure to chemicals, to select a suitable material.

- Speed: High-speed operations require couplings designed to handle the centrifugal forces and reduce vibration.

- Size and Space Constraints: Ensure the coupling fits within the available space and does not interfere with other components.

What Are the Classification of Couplings in Mechanical Engineering?

Mechanical couplings can be classified into several categories based on their construction and application:

- Rigid Couplings: Provide a solid connection between shafts, ideal for applications requiring precise alignment.

- Flexible Couplings: Accommodate misalignment and dampen vibrations, suitable for dynamic environments.

- Gear Couplings: Use toothed gears to transmit high torque while allowing for some misalignment.

- Fluid Couplings: Utilize hydraulic fluid to transmit power, offering smooth acceleration and torque control.

- Diaphragm Couplings: Use a flexible diaphragm to transmit torque while accommodating misalignment and axial movement.

About HZPT

HZPT is located in Hangzhou, Zhejiang Province, and is a modern enterprise integrating research and development, learning, production, and foreign trade. We adhere to the core values of “integrity” as our business philosophy, and we are united, enterprising, and innovative. We focus on the research and innovation of coupling products, combining high-tech development, international trade, industrial investment, and domestic and foreign networks. Our business spans Asia, Europe, Africa, and North America, aiming to become an internationally influential group. Our company specializes in producing various couplings, including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system, and our own technology development and testing department, with certifications such as CQC, ISO, and CE. We provide excellent sales service and technical support to our customers, serving over a hundred cooperative enterprises and adhering to the business philosophy of “people-oriented, customer first,” working sincerely with customers for mutual development.

Why Choose Our Mechanical Couplings?

Our mechanical couplings offer several advantages that make them the ideal choice for your needs:

- High-Quality Materials: We use premium materials to ensure durability and high performance, even in demanding conditions.

- Advanced Technology: Our products incorporate the latest technological advancements, providing superior reliability and efficiency.

- Custom Solutions: We offer custom coupling solutions tailored to meet the specific requirements of your applications.

- Comprehensive Support: Our technical support team is always available to assist with installation, maintenance, and troubleshooting.

- Global Reach: With a broad international presence, we can deliver products and support quickly and efficiently, no matter where you are located.