Mechanical Coupling for Border Control Equipment

The Role of Mechanical Coupling in Border Control Systems

Mechanical couplings play a critical role in border control systems by ensuring the efficient transfer of mechanical power between various components. These couplings are designed to handle high torque and ensure smooth operation under varying load conditions.

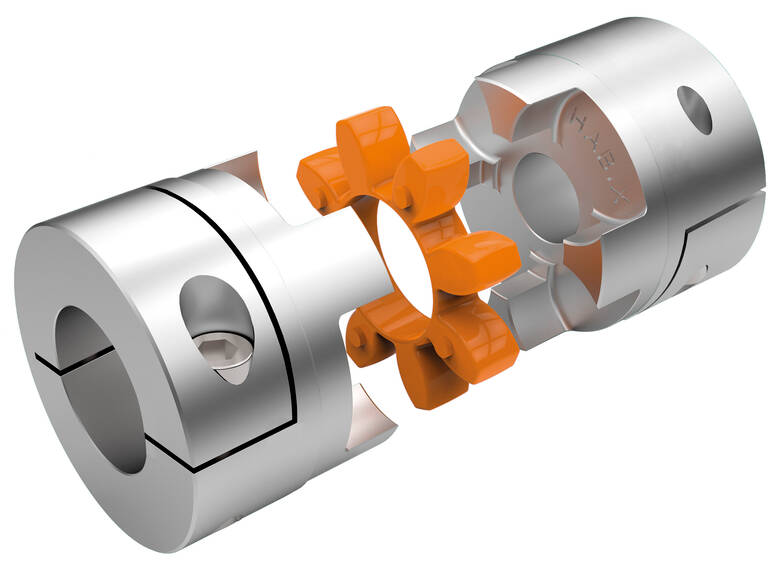

Types of Mechanical Couplings Used

Different types of mechanical couplings are used based on the specific requirements of border control systems. Some common types include flexible couplings, rigid couplings, and fluid couplings.

Advantages of Using Mechanical Couplings in Border Control

Mechanical couplings offer several advantages such as vibration damping, misalignment compensation, and maintenance ease. These benefits are crucial for the uninterrupted operation of border control equipment.

Materials Used in Mechanical Couplings

High-quality materials are essential for the durability and reliability of mechanical couplings. Common materials include steel, aluminum, and composite materials.

Design Considerations for Border Control Equipment

Designing mechanical couplings for border control equipment requires careful consideration of factors such as load capacity, environmental conditions, and operational speed.

Performance Metrics for Mechanical Couplings

Key performance metrics for mechanical couplings include torque capacity, stiffness, and damping characteristics. These metrics help in selecting the right coupling for specific applications.

Installation and Maintenance of Mechanical Couplings

Proper installation and regular maintenance are crucial for the longevity and performance of mechanical couplings. This includes lubrication, alignment checks, and periodic inspections.

Innovations in Mechanical Coupling Technology

Recent innovations in mechanical coupling technology include the development of smart couplings with embedded sensors for real-time monitoring and predictive maintenance.

Case Studies: Mechanical Couplings in Border Control

Several case studies highlight the successful implementation of mechanical couplings in border control systems, demonstrating their effectiveness in various scenarios.

Challenges in Implementing Mechanical Couplings

Challenges such as environmental exposure, load variations, and space constraints need to be addressed when implementing mechanical couplings in border control equipment.

Future Trends in Mechanical Coupling for Border Control

Future trends include the integration of IoT technologies, advanced materials, and enhanced simulation techniques to improve the performance and reliability of mechanical couplings.

Standards and Regulations

Compliance with international standards and regulations is essential for the deployment of mechanical couplings in border control systems to ensure safety and reliability.

Cost-Benefit Analysis

A comprehensive cost-benefit analysis helps in evaluating the long-term benefits of using mechanical couplings in border control equipment, factoring in initial costs, maintenance, and operational efficiency.

Sustainability and Environmental Impact

Sustainable practices in the production and use of mechanical couplings can reduce their environmental impact, supporting the development of eco-friendly border control systems.

Conclusion

The integration of mechanical couplings in border control equipment enhances the operational efficiency, reliability, and sustainability of these critical systems. As technology advances, the role of mechanical couplings will continue to evolve, offering new opportunities for innovation and improvement.

How does a mechanical coupling work?

A mechanical coupling works by connecting two shafts together, allowing them to rotate in unison while accommodating misalignment and transmitting torque. The coupling can be rigid or flexible, depending on the application requirements.

How do I choose a mechanical coupling?

To choose the right mechanical coupling, consider the following parameters and conditions:

- Torque Capacity: Ensure the coupling can handle the maximum torque generated by the system.

- Alignment Tolerance: Select a coupling that can accommodate any misalignment between connected shafts.

- Environmental Conditions: Consider factors such as temperature, humidity, and exposure to corrosive substances.

- Operational Speed: Choose a coupling that can operate efficiently at the desired rotational speed.

- Maintenance Requirements: Evaluate the ease of maintenance and the availability of replacement parts.

What are the classification of couplings in mechanical engineering?

In mechanical engineering, couplings are classified into several categories:

- Rigid Couplings: Used for precise alignment and high torque transmission without flexibility.

- Flexible Couplings: Allows for some misalignment and absorbs shock loads, enhancing system flexibility.

- Fluid Couplings: Utilizes fluid to transmit torque, offering smooth operation and overload protection.

- Magnetic Couplings: Transmits torque through magnetic fields, providing contactless power transfer and hermetic sealing.

- Universal Joints: Allows for significant angular misalignment and is used in applications requiring high flexibility.

HZPT: Your Trusted Partner for Mechanical Couplings

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise that integrates research and development, production, and international trade. We adhere to our core values of integrity and innovation, focusing on the development and innovation of coupling products. Our business spans Asia, Europe, Africa, and North America, aiming to become a globally influential international group.

We specialize in producing various coupling products such as drum couplings, pin bush couplings, serpentine spring couplings, universal couplings, star couplings, locking assemblies, disc couplings, and tire couplings. We have a comprehensive and scientific quality management system, along with our technology development and testing department, boasting certifications like CQC, ISO, and CE.

Here are some of our product and company advantages:

- High Quality: Our couplings are made from premium materials, ensuring durability and reliability.

- Innovative Solutions: We invest in R&D to bring innovative coupling solutions to our customers.

- Global Reach: Our extensive network allows us to serve clients worldwide, offering personalized support and services.

- Certified Excellence: Our products meet international standards, backed by certifications like ISO and CE.

- Customer-Centric Approach: We prioritize our customers’ needs, providing excellent sales and technical support to foster long-term partnerships.