Mechanical coupling for diamond drilling

Introduction to Mechanical Coupling in Diamond Drilling

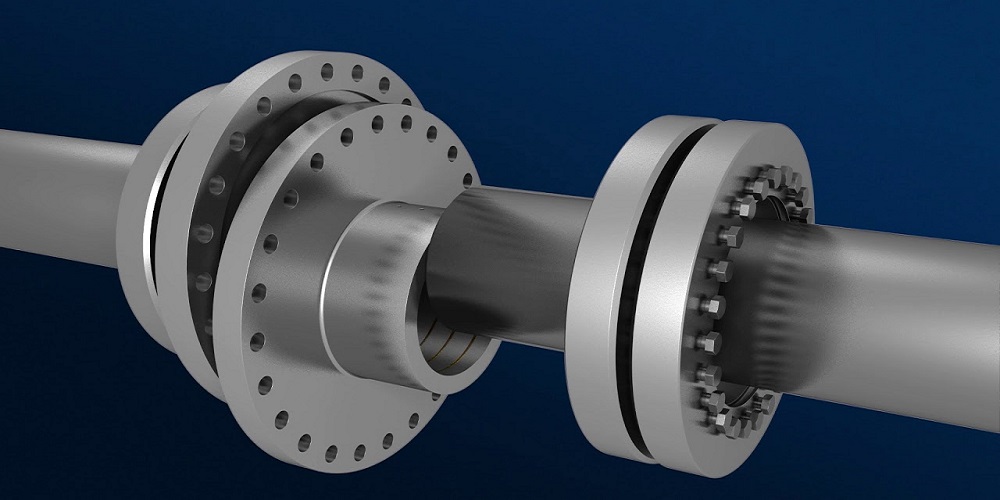

Mechanical coupling is an essential component in diamond drilling operations. It facilitates the transmission of torque and power between the driving machine and the drilling bit, ensuring efficiency and precision.

The Importance of Mechanical Coupling

Mechanical couplings are pivotal in maintaining the alignment and synchronization of rotating elements in drilling equipment. This alignment is crucial to prevent mechanical failures and ensure smooth operations.

Types of Mechanical Couplings Used in Diamond Drilling

Various types of mechanical couplings such as rigid, flexible, and fluid couplings are used in diamond drilling. Each type has its own advantages and applications based on the specific requirements of the drilling operation.

Rigid Couplings

Rigid couplings are ideal for applications where precise alignment is required. They provide a solid connection between the driving and driven shafts, minimizing any backlash or torsional play.

Flexible Couplings

Flexible couplings, including elastomeric and metallic couplings, can accommodate misalignments and absorb shock loads. These characteristics make them suitable for dynamic and fluctuating drilling environments.

Fluid Couplings

Fluid couplings use hydraulic fluid to transmit power and are known for their ability to provide smooth acceleration and deceleration, protecting the drilling machinery from sudden shocks.

Materials Used in Manufacturing Mechanical Couplings

Mechanical couplings are manufactured using materials such as steel, aluminum, and composites. The choice of material affects the coupling’s durability, weight, and performance.

Advantages of Using High-Quality Mechanical Couplings

High-quality mechanical couplings increase operational efficiency, reduce downtime, and extend the lifespan of drilling equipment. Investing in premium couplings can lead to significant cost savings over time.

Challenges in Mechanical Coupling for Diamond Drilling

Challenges include handling high torque, ensuring precise alignment, and dealing with the harsh environmental conditions encountered during drilling operations.

Maintenance of Mechanical Couplings

Regular maintenance of mechanical couplings is essential to prevent wear and tear, avoid equipment failures, and ensure continuous operation. Maintenance practices include lubrication, alignment checks, and periodic inspections.

Innovations in Mechanical Coupling Technologies

Advancements in materials science and engineering have led to the development of more robust and efficient mechanical couplings. Innovations include the use of advanced polymers and composite materials.

Application of Mechanical Couplings in Different Drilling Scenarios

Mechanical couplings are used in various drilling scenarios, from shallow exploratory drilling to deep mining operations. Their adaptability and reliability make them indispensable in the drilling industry.

Future Trends in Mechanical Coupling for Diamond Drilling

The future of mechanical coupling in diamond drilling looks promising, with ongoing research focused on enhancing coupling performance, reducing weight, and improving energy efficiency.

Case Studies of Mechanical Couplings in Diamond Drilling

Several case studies demonstrate the successful application of mechanical couplings in diamond drilling projects, highlighting their critical role in achieving operational success and efficiency.

Conclusion

Mechanical couplings are fundamental to the success of diamond drilling operations. Their ability to transmit power, accommodate misalignments, and withstand harsh conditions makes them an invaluable component in drilling machinery.

How does a mechanical coupling work?

A mechanical coupling works by connecting two rotating shafts, allowing them to transmit torque and power from one to the other while accommodating misalignments. It generally consists of two halves, one attached to each shaft, and a mechanism to join them securely, often through flanges, bolts, or flexible elements.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling depends on several parameters and actual conditions:

- Torque Requirements: The coupling must handle the maximum torque that will be transmitted without slipping or failing.

- Alignment Tolerance: Consider whether the system can maintain precise alignment or if the coupling needs to accommodate some degree of misalignment.

- Environmental Conditions: Factors such as temperature, humidity, and exposure to chemicals or abrasive materials will affect the choice of materials and design.

- Speed and Vibration: High-speed applications require couplings that can handle significant centrifugal forces and vibrations without degrading.

- Maintenance and Accessibility: Determine how easy it will be to install, inspect, and maintain the coupling in the given application.

What are the classification of couplings in mechanical engineering?

In mechanical engineering, couplings are classified into several types based on their design and functionality:

- Rigid Couplings: Provide a solid connection with no allowance for misalignment.

- Flexible Couplings: Accommodate misalignment and provide vibration damping. Examples include elastomeric and metallic couplings.

- Fluid Couplings: Use hydraulic fluid to transmit power smoothly and protect against shocks.

- Torsional Couplings: Handle variable torques and provide smooth power transmission.

- Magnetic Couplings: Transfer torque without physical contact, using magnetic fields.

HZPT is located in Hangzhou, Zhejiang Province, and is a modern enterprise integrating R&D, learning, production, and foreign trade. We uphold the core values of our company and operate under the philosophy of “integrity”, unity, progress, and innovation. We are committed to the research and innovation of coupling products, combining high-tech development, international trade, industrial investment, and domestic and international networks. Our business spans Asia, Europe, Africa, and North America, moving towards our vision of becoming a globally influential international group.

We specialize in the production of gear couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. With a complete and scientific quality management system and our own technical development and testing department, we are certified with CQC, ISO, CE, among others. We provide excellent sales service and technical support to our clients. Serving hundreds of cooperative enterprises, we adhere to the business philosophy of “people-oriented, customer first”, working sincerely with clients for mutual development.

We highly recommend our mechanical coupling products for your operations. Here are five key advantages of choosing our products and services:

- High-Quality Materials: We use advanced materials that ensure durability and performance under extreme conditions.

- Innovative Design: Our couplings are designed to handle high torque and misalignments, providing reliable performance in demanding environments.

- Extensive Range: We offer a wide variety of coupling types to meet diverse application needs.

- Technical Expertise: Our team of experts provides exceptional support and guidance to help you select and maintain the right couplings for your operations.

- Global Reach: With our international presence, we can deliver products and services to clients around the world, ensuring timely and efficient solutions.