Mechanical Coupling for Educational Lab Equipment

Introduction to Mechanical Coupling

Mechanical coupling is a critical component in various educational lab equipment, ensuring the seamless transmission of power and motion. It bridges the gap between different mechanical elements, ensuring synchronized operation.

Importance of Mechanical Coupling in Education

In educational settings, mechanical coupling plays a pivotal role in demonstrating fundamental principles of mechanics and engineering. It helps students understand real-world applications of theoretical concepts.

Types of Mechanical Couplings

There are diverse types of mechanical couplings, each engineered for specific applications. Understanding these types can enhance the efficiency and functionality of educational lab setups.

Rigid Couplings

Rigid couplings are used when precise alignment is crucial. They provide a solid connection between two shafts, ensuring minimal movement and high accuracy.

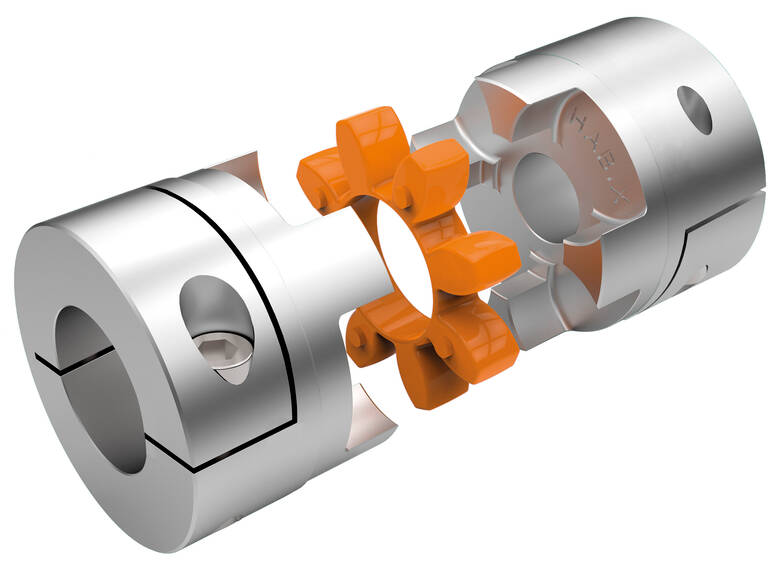

Flexible Couplings

Flexible couplings accommodate misalignment between shafts. They are ideal for applications where slight deviations are expected, providing flexibility and resilience.

Applications in Educational Labs

Mechanical couplings are integral to lab equipment such as wind tunnels, motor test rigs, and robotic arms. They enhance the functionality and durability of these instruments.

Material Considerations

The choice of material for couplings can affect their performance. Common materials include steel, aluminum, and composite materials, each offering distinct advantages.

Installation and Maintenance

Proper installation and regular maintenance of mechanical couplings are essential. Incorrect installation can lead to equipment failure, while routine maintenance ensures longevity and performance.

Advancements in Coupling Technology

Recent advancements in coupling technology have led to the development of more efficient and durable couplings. Innovations include smart couplings with integrated sensors for real-time monitoring.

Challenges in Educational Settings

Implementing mechanical couplings in educational environments poses unique challenges. These include ensuring compatibility with existing equipment and maintaining affordability.

Future Trends

The future of mechanical couplings in educational labs looks promising, with trends pointing towards increased automation and the use of adaptive technologies to enhance learning experiences.

Case Studies

Examining specific case studies where mechanical couplings have been successfully implemented in educational settings can provide valuable insights and best practices.

Benefits for Students

Students benefit significantly from the use of mechanical couplings in labs. They gain hands-on experience and a deeper understanding of mechanical systems and their applications.

Environmental Considerations

Environmental sustainability is an important factor in the design and use of mechanical couplings. Eco-friendly materials and manufacturing processes are becoming more prevalent.

Conclusion

Mechanical couplings are indispensable in educational labs. They not only enhance the functionality of equipment but also provide students with practical knowledge that bridges the gap between theory and practice.

How does a mechanical coupling work?

A mechanical coupling works by connecting two rotating shafts, allowing for the transmission of torque and motion. It compensates for minor misalignments and absorbs shocks, ensuring smooth and efficient operation.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling involves considering several critical parameters:

- Torque Requirements: The coupling must withstand the torque generated by the system without failure.

- Misalignment: Assess the maximum allowable misalignment the coupling can handle without compromising performance.

- Speed: The operational speed of the system affects the type of coupling suitable for the application.

- Environmental Conditions: Consider factors such as temperature, humidity, and exposure to chemicals, which can affect the coupling’s material and design.

- Size and Weight: The physical dimensions and weight of the coupling should match the system’s requirements to ensure compatibility and ease of installation.

What are the classification of couplings in mechanical engineering?

Mechanical couplings can be classified into several categories:

- Rigid Couplings: Provide a solid connection between shafts without allowing for misalignment.

- Flexible Couplings: Allow for slight misalignments and provide flexibility to the system.

- Fluid Couplings: Use fluid to transmit power, providing smooth and controlled acceleration.

- Magnetic Couplings: Use magnetic fields to transmit torque, offering non-contact coupling solutions.

- Universal Joints: Allow for high angular misalignments, suitable for applications with complex motion requirements.

HZPT: Your Trusted Partner in Mechanical Couplings

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, learning, production, and foreign trade. We uphold the core values of our company, with “integrity” as our business philosophy, fostering unity, progress, and innovation. Our high-tech development, international trade, industrial investment, and domestic and foreign networks are centered on the research and innovation of coupling products. Our business spans Asia, Europe, Africa, and North America, progressing towards our vision of becoming an internationally influential enterprise group.

We specialize in producing drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, tire couplings, and other series of coupling products. Our comprehensive and scientific quality management system, along with our technical development and testing departments, have earned us certifications such as CQC, ISO, and CE. We provide excellent sales services and technical support to our customers, serving hundreds of cooperative enterprises. Adhering to the business philosophy of “people-oriented, customer-first,” we collaborate with customers for mutual development.

Why Choose Our Mechanical Couplings?

- High-Quality Materials: Our couplings are made from premium materials, ensuring durability and reliability in various applications.

- Advanced Technology: Incorporating cutting-edge technology in our products, we deliver solutions that meet the highest industry standards.

- Custom Solutions: We offer customized coupling solutions tailored to meet the specific needs of our clients, ensuring optimal performance and compatibility.

- Global Reach: With a robust international network, we provide products and services to customers worldwide, ensuring timely delivery and support.

- Comprehensive Support: Our dedicated team offers continuous technical assistance and after-sales support, ensuring customer satisfaction and long-term partnerships.