Mechanical Coupling for Exhibition Setup

Introduction to Mechanical Couplings

Mechanical couplings are quintessential components in the realm of mechanical engineering. Their utilizations span various sectors, including the setup of exhibitions, where they ensure the seamless integration of moving parts.

The Role of Mechanical Coupling in Exhibitions

Exhibitions demand precision in assembly and disassembly. Mechanical couplings play a pivotal role in this by providing reliable connections that are both temporary and robust.

Types of Mechanical Couplings Used in Exhibitions

From rigid couplings to flexible ones, the types of mechanical couplings vary based on the requirements of the exhibition setup. Each type offers distinct advantages and is selected based on specific criteria.

Advantages of Using Mechanical Couplings

Mechanical couplings offer numerous benefits, including ease of installation, flexibility, and durability. These characteristics make them indispensable in exhibition setups.

Design Considerations for Mechanical Couplings

Designing a mechanical coupling requires meticulous consideration of factors such as load capacity, alignment needs, and environmental conditions. These factors ensure the efficiency and longevity of the couplings.

Custom Mechanical Couplings for Exhibitions

Customized mechanical couplings can be tailored to meet the unique demands of exhibition setups, offering bespoke solutions that enhance the overall performance and ease of use.

Installation Techniques for Mechanical Couplings

Proper installation techniques are crucial for the optimal performance of mechanical couplings. This includes ensuring correct alignment and torque settings.

Maintenance of Mechanical Couplings

Regular maintenance is essential to preserve the functionality and extend the lifespan of mechanical couplings. This involves periodic inspections and lubrication.

Innovations in Mechanical Coupling Technology

Recent advancements in mechanical coupling technology have led to the development of more efficient and resilient couplings, suitable for a wide range of applications, including exhibitions.

Real-World Applications of Mechanical Couplings

Mechanical couplings are not only used in exhibitions but also in various industrial applications, demonstrating their versatility and reliability.

Challenges in Mechanical Coupling Integration

Despite their benefits, integrating mechanical couplings into exhibition setups can pose challenges, such as ensuring compatibility and handling misalignments.

Case Studies: Successful Exhibition Setups

Examining case studies of successful exhibition setups can provide valuable insights into the effective use of mechanical couplings, highlighting best practices and common pitfalls.

Future Trends in Mechanical Coupling for Exhibitions

The future of mechanical coupling technology promises further innovations that will enhance their application in exhibition setups, making them more adaptable and efficient.

Environmental Impact of Mechanical Couplings

Considering the environmental impact of mechanical couplings is vital. Sustainable materials and eco-friendly manufacturing processes are becoming increasingly important in their production.

Conclusion: The Essential Role of Mechanical Couplings

In conclusion, mechanical couplings are essential for the successful setup and operation of exhibitions. Their reliability, flexibility, and ease of use make them indispensable components in this field.

How Does a Mechanical Coupling Work?

A mechanical coupling works by connecting two rotating shafts to transmit power and torque. It ensures alignment and accommodates misalignment between the shafts, providing a seamless transfer of motion. The coupling absorbs shock and vibration, protecting the connected machinery from excessive stress and wear.

How Do I Choose a Mechanical Coupling?

Choosing the right mechanical coupling requires consideration of several parameters:

- Torque Requirements: Determine the torque that needs to be transmitted to ensure the coupling can handle the load without failure.

- Speed: Consider the operational speed of the machinery. High-speed applications may require couplings designed to minimize vibration and noise.

- Misalignment: Evaluate the potential misalignment between the connected shafts. Flexible couplings can accommodate more misalignment compared to rigid ones.

- Environmental Conditions: Take into account the operating environment, including temperature, humidity, and exposure to chemicals, to select a coupling that can withstand these conditions.

- Space Constraints: Assess the available space for the coupling. Some designs are more compact and suitable for confined spaces.

What Are the Classifications of Couplings in Mechanical Engineering?

In mechanical engineering, couplings are classified into several categories based on their design and function:

- Rigid Couplings: Provide a fixed connection with no flexibility, used in applications where precise alignment is crucial.

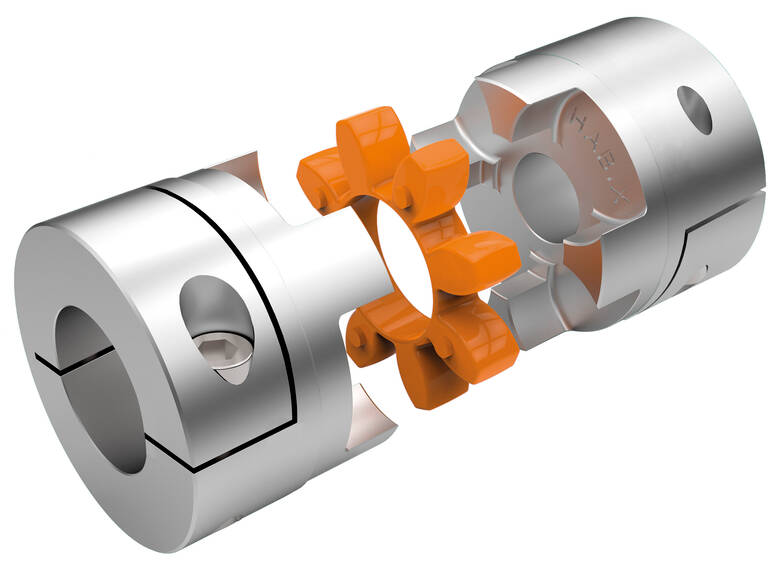

- Flexible Couplings: Can accommodate misalignment and absorb shock and vibration, ideal for dynamic applications.

- Fluid Couplings: Use hydraulic fluid to transmit torque, providing smooth power transmission and overload protection.

- Magnetic Couplings: Utilize magnetic fields to transmit torque without physical contact, offering a non-contact solution.

- Universal Couplings: Allow for angular misalignment between connected shafts, commonly used in automotive and aerospace applications.

HZPT: Your Trusted Partner in Mechanical Couplings

HZPT, based in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, learning, production, and foreign trade. We adhere to our core values of integrity and operate with a spirit of unity, progress, and innovation. Our focus is on the research and innovation of coupling products, and our business spans Asia, Europe, Africa, and North America as we strive to become an influential international group.

Our company specializes in producing various coupling products, including drum-shaped couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system, our own technical development and testing department, and certifications such as CQC, ISO, and CE. We offer excellent sales services and technical support to our clients. Here are five key advantages of our products and company:

- High-Quality Products: Our products undergo stringent quality control, ensuring they meet international standards and deliver reliable performance.

- Innovative Solutions: We invest in R&D to develop innovative coupling solutions that cater to the evolving needs of various industries.

- Comprehensive Support: Our technical support team provides expert guidance and assistance, ensuring customers can make the most of our products.

- Global Reach: With a robust international network, we serve clients across multiple continents, offering timely and efficient services.

- Customization Options: We offer customized coupling solutions tailored to specific requirements, enhancing the compatibility and performance of our products in diverse applications.

We look forward to collaborating with you and offering the best mechanical coupling solutions to meet your needs.