Mechanical Coupling for Freight Rail Systems

Introduction to Mechanical Coupling

Mechanical coupling is an essential component in the operation of freight rail systems. It ensures the transmission of power and motion between different parts of the system, allowing for the efficient and safe transport of goods.

The Importance of Coupling in Freight Rail Systems

Effective coupling is crucial for the stability and reliability of freight rail systems. It minimizes the risk of detachment and accidents, enhancing the overall safety of the transport process.

Types of Mechanical Couplings

There are various types of mechanical couplings used in freight rail systems, each designed to meet specific requirements. These include rigid couplings, flexible couplings, and fluid couplings.

Rigid Couplings

Rigid couplings are used when precise alignment and a strong, permanent connection are required. They are typically made from durable materials such as steel or cast iron.

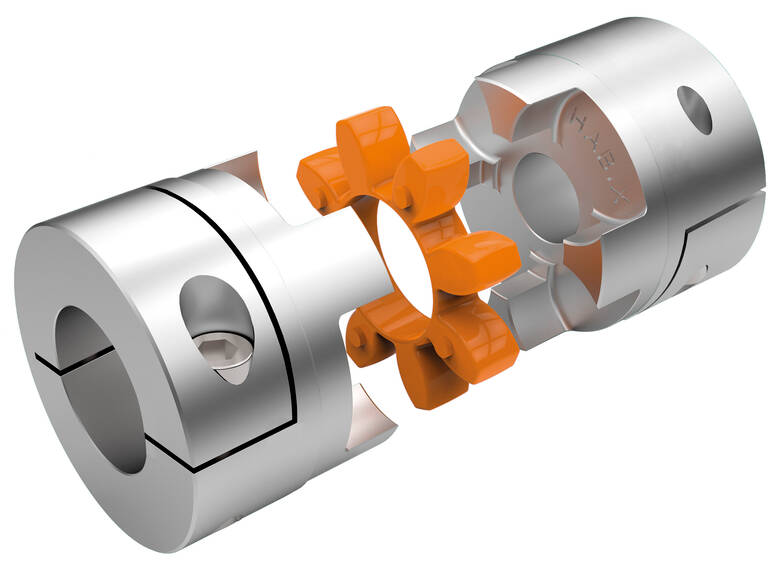

Flexible Couplings

Flexible couplings accommodate misalignment and absorb shock loads, reducing wear and tear on the connected components. They are often used in applications where some degree of flexibility is necessary.

Fluid Couplings

Fluid couplings use a hydraulic fluid to transmit power, allowing for smooth acceleration and reducing mechanical stress. They are especially useful in heavy-duty freight rail systems.

Components of Mechanical Couplings

Mechanical couplings consist of several key components, including hubs, sleeves, and fasteners. Each component plays a vital role in ensuring the coupling’s effectiveness and reliability.

Hubs

Hubs are the central part of the coupling, connecting directly to the shafts of the machinery. They provide a secure attachment point for the other components.

Sleeves

Sleeves encase the hubs and provide flexibility or rigidity, depending on the type of coupling. They help distribute the load evenly across the connection.

Fasteners

Fasteners secure the hubs and sleeves together, ensuring a strong and stable connection. They are typically made from high-strength materials to withstand the forces involved.

Material Selection for Couplings

The choice of materials for mechanical couplings is critical to their performance and longevity. Common materials include steel, aluminum, and composite materials, each offering different advantages.

Steel Couplings

Steel couplings are known for their strength and durability, making them ideal for heavy-duty applications. They can withstand high torque and harsh operating conditions.

Aluminum Couplings

Aluminum couplings are lightweight and corrosion-resistant, making them suitable for applications where weight and environmental factors are important considerations.

Composite Couplings

Composite couplings offer a balance of strength and flexibility, providing good performance in a range of conditions. They are often used in specialized applications where traditional materials may not be suitable.

Maintenance of Mechanical Couplings

Regular maintenance is essential to ensure the longevity and reliability of mechanical couplings. This includes periodic inspections, lubrication, and replacement of worn components.

Inspection and Lubrication

Routine inspections can identify potential issues before they lead to failure. Lubrication reduces friction and wear, extending the life of the coupling.

Replacement of Worn Components

Timely replacement of worn components is crucial to maintaining the performance and safety of the coupling. Using high-quality replacement parts ensures continued reliability.

Technological Advancements in Coupling Design

Advancements in materials science and engineering have led to the development of more efficient and reliable mechanical couplings. Modern designs offer improved performance and reduced maintenance requirements.

How does a mechanical coupling work?

A mechanical coupling works by connecting two rotating shafts, allowing them to transmit torque and motion from one to the other. The coupling compensates for minor misalignments and absorbs shock loads, ensuring smooth and efficient operation. The components of the coupling, such as hubs, sleeves, and fasteners, work together to create a secure and stable connection.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling involves several critical considerations:

- Load Capacity: The coupling must be able to handle the maximum load and torque that will be transmitted through it. This ensures that the coupling will perform reliably under all operating conditions.

- Misalignment Tolerance: The coupling should accommodate any misalignment between the connected shafts, whether axial, angular, or parallel. This reduces stress on the machinery and prolongs the life of the coupling.

- Environmental Conditions: Consider the operating environment, including temperature, humidity, and exposure to corrosive substances. Choose a material and design that will withstand these conditions.

- Maintenance Requirements: Some couplings require more frequent maintenance than others. Consider the maintenance schedule and ease of access to determine the best fit for your application.

- Cost: Budget constraints are always a factor. Balance the initial cost with the long-term benefits and maintenance costs to choose the most cost-effective solution.

What are the classification of couplings in mechanical engineering?

In mechanical engineering, couplings are classified into several categories based on their design and application:

- Rigid Couplings: Provide a solid connection with no flexibility, used for precise alignment and high torque applications.

- Flexible Couplings: Allow for some misalignment and absorb shocks, reducing wear on the connected machinery.

- Fluid Couplings: Use hydraulic fluid to transmit power, ideal for smooth acceleration and heavy-duty applications.

- Universal Joints: Allow for high degrees of angular misalignment, commonly used in automotive and industrial applications.

- Oldham Couplings: Compensate for parallel misalignment and provide a compact design, often used in printing and textile machinery.

HZPT is located in Hangzhou, Zhejiang Province, and is a modern enterprise integrating R&D, learning, production, and foreign trade. We uphold our core values of “integrity” as our business philosophy, fostering unity, progress, and innovation. We integrate high-tech development, international trade, industrial investment, and domestic and international networks, focusing on the research and innovation of coupling products. Our business spans Asia, Europe, Africa, and North America, moving towards the vision of becoming an internationally influential enterprise group. Our company specializes in producing drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, tire couplings, and other series of coupling products. We have a complete, scientific quality management system and our own technology development and testing department, with certifications such as CQC, ISO, and CE. We can provide customers with good sales service and technical support. We serve hundreds of cooperative enterprises, adhering to the business philosophy of “people-oriented, customer first,” working sincerely with customers for mutual development.

Why Choose Our Mechanical Couplings?

Our mechanical couplings offer several advantages, making them the preferred choice for many customers:

- High Quality: Our couplings are manufactured using premium materials and advanced technology, ensuring durability and reliability.

- Wide Range of Products: We offer a comprehensive selection of coupling types to meet various application needs, from rigid to flexible and fluid couplings.

- Customization Options: We provide tailored solutions to meet the specific requirements of our customers, ensuring optimal performance and satisfaction.

- Excellent Customer Support: Our experienced team offers professional advice and technical support, helping customers choose the best coupling for their needs.

- Global Reach: With a strong presence in multiple continents, we are well-positioned to serve customers worldwide, offering timely delivery and efficient service.