“`html

Mechanical Coupling for Gold Mining Equipment

Introduction to Mechanical Coupling

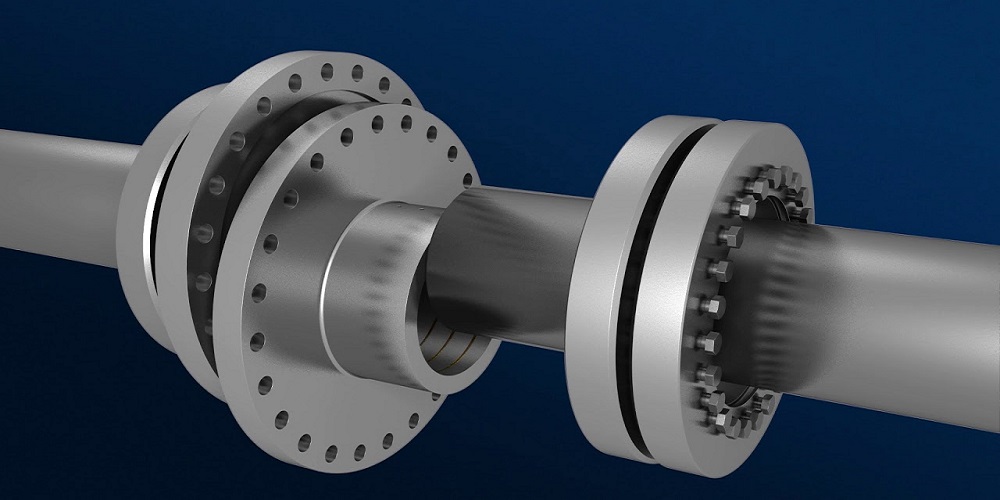

Mechanical coupling is an essential component in gold mining equipment, responsible for transmitting torque and power between shafts. It connects two rotating elements, allowing for efficient energy transfer and operational stability.

Types of Mechanical Couplings

There are various types of mechanical couplings used in gold mining equipment, each designed to accommodate different operational requirements and constraints. These include flexible, rigid, and fluid couplings.

Flexible Couplings

Flexible couplings are designed to accommodate misalignment and absorb shock loads. They are commonly used in gold mining equipment to enhance operational resilience and prolong the lifespan of machinery.

Rigid Couplings

Rigid couplings provide a solid connection between shafts, ensuring precise alignment. They are typically used in applications where exact positioning and high torque transmission are critical.

Fluid Couplings

Fluid couplings use hydraulic fluid to transmit power, offering smooth and controlled torque transmission. They are particularly effective in heavy-duty gold mining machinery, where load variations are frequent.

Functionality in Gold Mining Equipment

In gold mining, mechanical couplings play a crucial role in various equipment such as crushers, conveyors, and mills. They ensure seamless operation and minimize downtime by efficiently transferring power between components.

Advantages of Using Mechanical Couplings

Mechanical couplings offer multiple advantages, including high torque capacity, shock absorption, misalignment accommodation, and easy maintenance. These features contribute to the overall efficiency and reliability of gold mining operations.

Materials Used in Couplings

Couplings are made from various materials like steel, aluminum, and composite materials. The choice of material depends on the operational demands, such as load capacity, temperature resistance, and environmental conditions.

Design Considerations

Designing a mechanical coupling involves considering factors like torque requirements, misalignment tolerance, operational speed, and environmental conditions. These considerations ensure optimal performance and durability.

Installation and Maintenance

Proper installation and regular maintenance of mechanical couplings are essential for their longevity and performance. Regular inspections, lubrication, and alignment checks are crucial maintenance practices.

Common Issues and Troubleshooting

Common issues with mechanical couplings include misalignment, wear and tear, and excessive vibration. Troubleshooting these issues involves regular monitoring and timely interventions to prevent equipment failure.

Technological Advancements

Recent advancements in coupling technology have led to the development of more efficient and durable couplings. Innovations like self-aligning couplings and advanced materials have significantly improved performance.

Environmental Impact

Mechanical couplings contribute to the sustainability of mining operations by reducing energy consumption and minimizing mechanical wear. Their efficient power transmission capabilities result in lower operational costs and environmental impact.

Future Trends

The future of mechanical couplings in gold mining looks promising with ongoing research and development. Future trends include the integration of smart technologies and the use of eco-friendly materials to enhance operational efficiency and sustainability.

Conclusion

Mechanical couplings are indispensable components in gold mining equipment, providing efficient power transmission and operational stability. With advancements in technology and materials, their role in enhancing mining operations continues to grow.

How does a mechanical coupling work?

A mechanical coupling works by connecting two rotating shafts, allowing for the transfer of torque and rotational energy. The coupling can accommodate misalignment and absorb shock loads, ensuring smooth and efficient power transmission.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling involves considering several parameters and operational conditions:

- Torque Requirements: Evaluate the torque needs of your equipment to ensure the coupling can handle the load.

- Misalignment Tolerance: Assess the degree of misalignment the coupling will need to accommodate.

- Operational Speed: Consider the rotational speed of the equipment, as high-speed applications require specific coupling types.

- Environmental Conditions: Factor in temperature, humidity, and exposure to corrosive substances to select a suitable material.

- Maintenance Requirements: Determine the maintenance needs and ease of installation for the selected coupling.

What are the classification of couplings in mechanical engineering?

Couplings in mechanical engineering can be classified into several categories based on their design and functionality:

- Flexible Couplings: These include elastomeric couplings, jaw couplings, and gear couplings, designed to absorb misalignment and shock loads.

- Rigid Couplings: Examples include clamp couplings and sleeve couplings, used for precise alignment and high torque transmission.

- Fluid Couplings: These use hydraulic fluid for smooth torque transmission, ideal for applications with variable loads.

- Universal Joints: Also known as U-joints, they are used for connecting shafts at an angle, allowing for rotational motion transmission.

- Disc Couplings: These couplings use a series of thin, flexible discs to transmit torque and accommodate misalignment.

HZPT: Your Trusted Partner for Mechanical Couplings

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, manufacturing, and international trade. We adhere to the core values of “integrity” and adopt a business philosophy focused on unity, progress, and innovation. Our company combines high-tech development, international trade, industrial investment, and a domestic and international network, concentrating on the research and innovation of coupling products. Servicing over 100 partners, we offer excellent sales services and technical support, with a business presence in Asia, Europe, Africa, and North America, aiming to become a globally influential international group.

We specialize in producing a wide range of couplings including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, locking assemblies, diaphragm couplings, and tire couplings. Our products and company offer several advantages:

- Comprehensive Quality Management: We have a complete and scientific quality management system, ensuring high standards in production.

- Advanced Technology Development: Our dedicated technical development and testing department focuses on innovation and reliability.

- Global Certifications: Our products are certified by CQC, ISO, and CE, ensuring compliance with international standards.

- Wide Range of Products: We offer a diverse selection of couplings to meet various industrial needs and applications.

- Excellent Customer Service: We prioritize a customer-centric approach, providing exceptional sales services and after-sales support.

Choose HZPT for reliable and innovative mechanical coupling solutions that drive your success in the mining industry.

“`