Mechanical coupling for golf course machinery

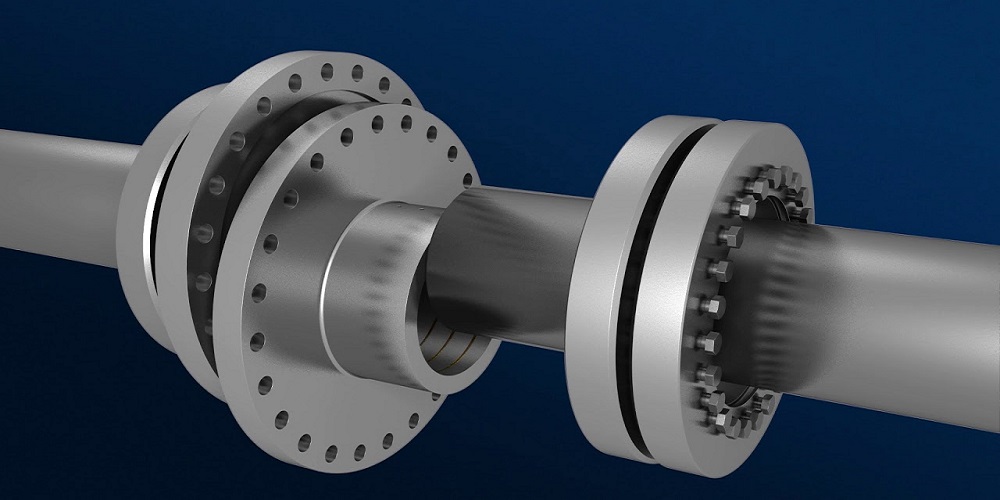

Introduction to Mechanical Coupling

Mechanical couplings are essential components in golf course machinery, ensuring smooth operation and efficient power transmission. They are crucial in connecting various parts of the machinery, allowing for optimal performance.

Types of Mechanical Couplings

There are several types of mechanical couplings used in golf course machinery. Each type has unique characteristics that make them suitable for specific applications. Common types include rigid couplings, flexible couplings, and fluid couplings.

Rigid Couplings

Rigid couplings are used where precise alignment is required. They provide a strong and durable connection between two shafts, ensuring no relative movement.

Flexible Couplings

Flexible couplings are designed to accommodate slight misalignments and absorb shocks. They are ideal for machinery that experiences variable loads and vibrations.

Fluid Couplings

Fluid couplings use hydraulic fluid to transmit power. These couplings are known for their smooth operation and ability to handle high torque.

Benefits of Using Mechanical Couplings

Mechanical couplings offer numerous benefits, including improved efficiency, reduced maintenance costs, and enhanced machinery lifespan. They also help in minimizing downtime and ensuring continuous operation.

Applications in Golf Course Machinery

Mechanical couplings are widely used in various golf course machinery, such as mowers, tractors, and irrigation systems. They ensure these machines operate smoothly and efficiently.

Customization Options

Customized mechanical couplings can be designed to meet specific requirements of golf course machinery. This customization ensures optimal performance and compatibility with existing systems.

Material Selection

The choice of material for mechanical couplings depends on the application and operating conditions. Common materials include steel, aluminum, and composite materials.

Maintenance and Care

Regular maintenance and proper care are essential for the longevity of mechanical couplings. This includes regular inspections, lubrication, and timely replacements of worn-out components.

Installation Guidelines

Proper installation is crucial for the effective functioning of mechanical couplings. It involves ensuring correct alignment, securing all components, and following manufacturer guidelines.

Common Issues and Troubleshooting

Common issues with mechanical couplings include misalignment, wear and tear, and improper installation. Troubleshooting involves identifying the root cause and taking corrective measures.

Technological Advancements

Recent technological advancements have led to the development of more efficient and durable mechanical couplings. Innovations include the use of advanced materials and precision manufacturing techniques.

Environmental Considerations

Environmental factors such as temperature, humidity, and exposure to chemicals can affect the performance of mechanical couplings. Selecting the right coupling for specific environmental conditions is crucial.

Future Trends

The future of mechanical couplings in golf course machinery looks promising, with ongoing research and development aimed at enhancing performance and durability. Emerging trends include the integration of smart technologies and real-time monitoring systems.

How does a mechanical coupling work?

A mechanical coupling works by connecting two rotating shafts, allowing them to transmit power and movement. The coupling ensures that the shafts are aligned and can accommodate minor misalignments and vibrations. It effectively transfers torque from one shaft to another, enabling the connected machinery to operate smoothly.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling involves considering several parameters and actual conditions:

- Torque Requirements: Determine the amount of torque that needs to be transmitted to ensure the coupling can handle the load.

- Speed: Consider the operating speed of the machinery to select a coupling that can withstand the rotational velocity.

- Misalignment: Assess the degree of misalignment that the coupling needs to accommodate, including angular, parallel, and axial misalignments.

- Environmental Conditions: Evaluate the environmental factors such as temperature, humidity, and chemical exposure that the coupling will be subjected to.

- Material Compatibility: Choose a coupling made from materials that are compatible with the specific operating conditions and requirements.

What are the classifications of couplings in mechanical engineering?

Mechanical engineering classifies couplings into various categories based on their design and function:

- Rigid Couplings: Used for precise alignment and strong, durable connections.

- Flexible Couplings: Designed to accommodate misalignments and absorb shocks and vibrations.

- Fluid Couplings: Utilize hydraulic fluid for smooth power transmission and high torque handling.

- Universal Couplings: Allow for the transmission of power between shafts that are not in a straight line.

- Diaphragm Couplings: Offer high torsional stiffness and can accommodate misalignments.

About HZPT

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, production, learning, and foreign trade. We uphold the core values of the company and operate with “integrity” as our business philosophy, emphasizing unity, progress, and innovation. We focus on the research and innovation of coupling products, with a strong presence in Asia, Europe, Africa, and North America. Our aim is to become a globally influential international group. We specialize in producing a variety of coupling products, including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings.

We have a complete and scientific quality management system, along with our own technical development and testing department. Our certifications include CQC, ISO, and CE. We offer excellent sales service and technical support to our clients. With over a hundred cooperative enterprises, we adhere to the business philosophy of “people-oriented, customer first,” working closely with our clients for mutual development.

Why Choose Our Products?

We recommend our mechanical couplings for the following reasons:

- High-Quality Materials: Our couplings are made from top-grade materials, ensuring durability and long service life.

- Advanced Technology: We utilize the latest manufacturing techniques to produce precise and reliable couplings.

- Customization Options: We offer customized solutions tailored to meet specific requirements and applications.

- Comprehensive Support: Our dedicated team provides extensive technical support and after-sales service to ensure customer satisfaction.

- Global Presence: With a strong international presence, we are well-positioned to serve clients worldwide efficiently.