Mechanical Coupling for Meat Packing Plants

The Importance of Mechanical Coupling in Meat Packing Plants

In the fast-paced world of meat packing plants, operational efficiency is paramount. Mechanical couplings play a crucial role in ensuring the seamless transfer of power between various machinery components, thereby minimizing downtime and maintaining consistent production rates.

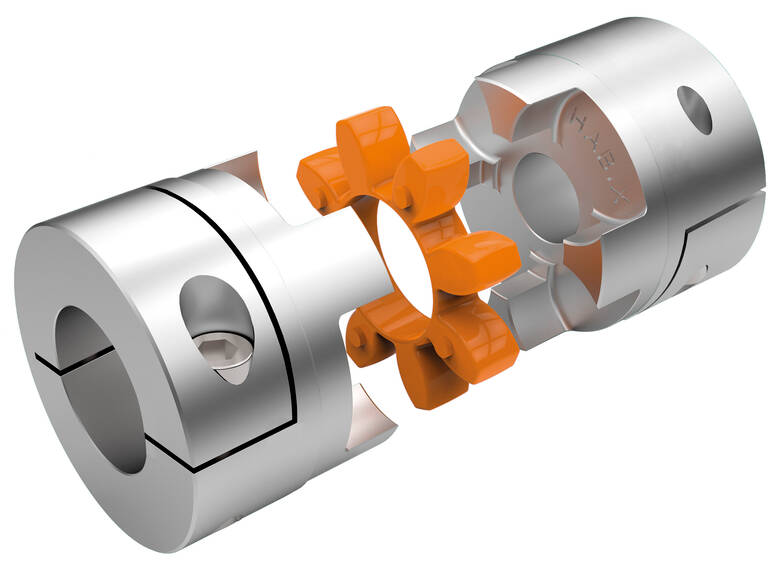

Understanding Mechanical Couplings

Mechanical couplings are devices used to connect two shafts together at their ends for the purpose of transmitting power. They serve as critical components that accommodate misalignment, reduce shock loads, and offer protection against overloads.

Types of Mechanical Couplings

There are several types of mechanical couplings used in meat packing plants, including rigid couplings, flexible couplings, and fluid couplings. Each type has its unique applications and benefits.

Applications in Meat Packing Plants

Mechanical couplings are used in various stages of meat processing, from cutting and grinding to packaging. They ensure that all machinery operates in harmony, thereby enhancing productivity and reducing operational costs.

Advantages of Using Mechanical Couplings

Mechanical couplings offer numerous advantages, such as improved machinery alignment, reduced wear and tear, and enhanced safety. They also enable smoother operation and longer equipment lifespan.

Selection Criteria for Mechanical Couplings

Choosing the right mechanical coupling is vital for optimal performance. Factors to consider include torque requirements, shaft sizes, and operational environment. Proper selection ensures reliability and efficiency.

Installation and Maintenance

Proper installation and regular maintenance of mechanical couplings are essential for their longevity. Adhering to manufacturer guidelines and conducting routine inspections can prevent unexpected failures.

Common Challenges and Solutions

Challenges such as misalignment, vibration, and wear are common in mechanical couplings. Implementing precise alignment techniques and using high-quality materials can mitigate these issues.

Innovations in Mechanical Coupling Technology

Advancements in materials science and engineering have led to the development of more robust and efficient mechanical couplings. Innovations such as composite materials and smart monitoring systems are transforming the industry.

Case Study: Efficiency in Meat Packing Plants

A recent case study on a leading meat packing plant demonstrated how the implementation of advanced mechanical couplings reduced downtime by 20% and increased overall productivity.

Environmental Impact

Mechanical couplings contribute to energy efficiency by reducing friction and wear. This leads to lower energy consumption and a reduced carbon footprint, aligning with sustainable industry practices.

Cost Considerations

While the initial investment in high-quality mechanical couplings may be higher, the long-term savings in maintenance and downtime make them a cost-effective choice for meat packing plants.

Future Trends in Mechanical Couplings

Future trends in mechanical coupling technology include the integration of IoT for real-time monitoring and predictive maintenance. These advancements will further enhance the reliability and efficiency of meat packing operations.

Expert Recommendations

Industry experts recommend regular training for maintenance personnel, investing in high-quality couplings, and adopting a proactive maintenance strategy to ensure the best performance of mechanical couplings.

Conclusion

Mechanical couplings are indispensable in meat packing plants, ensuring efficient and reliable operation. By understanding their importance and selecting the right couplings, plants can achieve optimal performance and longevity of their machinery.

How Does a Mechanical Coupling Work?

Mechanical couplings work by connecting two rotating shafts to transmit power between them. They accommodate misalignment and minimize vibration, ensuring smooth and efficient power transfer.

How Do I Choose a Mechanical Coupling?

Choosing the right mechanical coupling involves considering several parameters and actual conditions:

- Torque Requirements: Determine the torque requirements of your application to ensure the coupling can handle the load without failure.

- Shaft Sizes: Ensure the coupling is compatible with the shaft sizes of your machinery to provide a secure and efficient connection.

- Operational Environment: Consider the environmental conditions, such as temperature, humidity, and exposure to chemicals, to select a coupling that can withstand these factors.

- Misalignment Accommodation: Evaluate the degree of misalignment that the coupling can accommodate without compromising performance.

- Material: Select a coupling made from materials suitable for your application, such as stainless steel for corrosion resistance or composite materials for lightweight applications.

What Are the Classifications of Couplings in Mechanical Engineering?

Couplings in mechanical engineering can be classified into several categories:

- Rigid Couplings: Used where precise alignment is required, rigid couplings provide a strong and inflexible connection.

- Flexible Couplings: These couplings accommodate misalignment and provide flexibility to absorb shocks and vibrations.

- Fluid Couplings: Utilizing fluid to transmit power, these couplings offer smooth and controlled power transfer.

- Magnetic Couplings: Employing magnetic forces, these couplings provide a non-contact method of power transmission, ideal for sealed and sterile environments.

- Gear Couplings: Featuring gear teeth, these couplings allow for high torque transmission and accommodate angular misalignment.

HZPT: Leading Manufacturer of Mechanical Couplings

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, learning, production, and foreign trade. We adhere to our core values of “integrity” as our business philosophy, fostering unity, progress, and innovation. Our expertise lies in the research and innovation of coupling products, with our business spanning Asia, Europe, Africa, and North America. We are committed to becoming a globally influential international group enterprise.

We specialize in manufacturing a range of mechanical couplings, including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. Our complete and scientific quality management system, coupled with our own technical development and testing department, ensures the highest standards of quality. We hold CQC, ISO, and CE certifications and provide excellent sales service and technical support to our customers.

Our company has over 100 cooperating enterprises, adhering to the philosophy of “people-oriented, customer first,” working sincerely with customers for mutual development.

Why Choose Our Mechanical Couplings?

We offer several advantages that make our mechanical couplings the ideal choice for your needs:

- High-Quality Materials: Our couplings are made from premium materials, ensuring durability and long-lasting performance.

- Advanced Technology: Leveraging the latest technological advancements, our couplings provide superior efficiency and reliability.

- Custom Solutions: We offer customized coupling solutions tailored to meet the specific requirements of your applications.

- Global Reach: With a strong presence in multiple continents, we provide timely and efficient service to our international clients.

- Comprehensive Support: Our dedicated technical support team is available to assist with installation, maintenance, and troubleshooting, ensuring the smooth operation of your machinery.