Mechanical Coupling for Postal Sorting Machinery

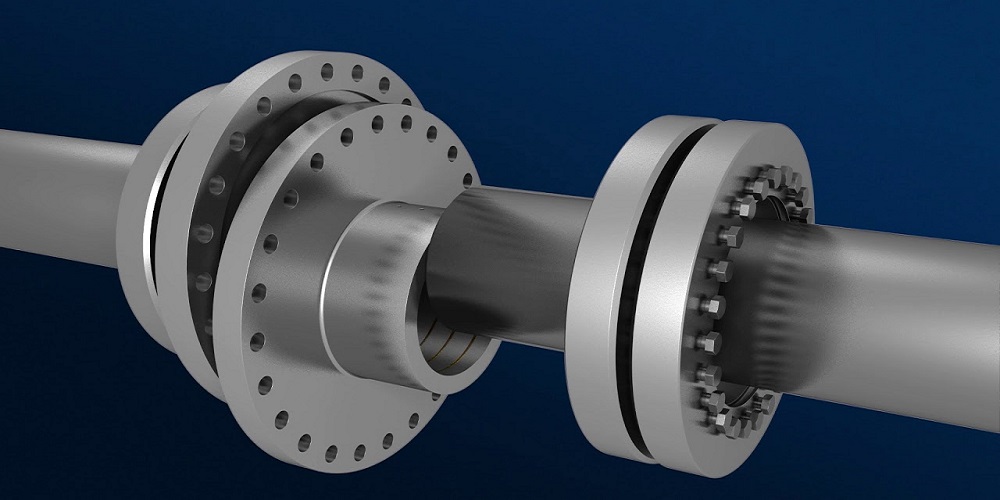

Introduction to Mechanical Coupling

Mechanical coupling plays a pivotal role in the efficiency of postal sorting machinery. These couplings connect various mechanical components and ensure synchronized movement, reducing downtime and enhancing performance.

Types of Mechanical Couplings

Mechanical couplings come in various forms, each suitable for specific applications. Common types include rigid, flexible, and fluid couplings, each offering distinct advantages.

Rigid Couplings

Rigid couplings are designed to connect two shafts in a precise alignment. They are ideal for applications requiring exacting shaft positioning and minimal flexibility.

Flexible Couplings

Flexible couplings, such as gear and elastomeric couplings, allow for misalignment and absorb shock, which is essential in systems with varying load conditions.

Fluid Couplings

Fluid couplings utilize hydraulic fluid to transmit torque, providing smooth acceleration and deceleration, which is crucial in high-speed postal sorting machinery.

Benefits of Using Mechanical Couplings

Mechanical couplings offer several benefits including improved efficiency, reduced wear and tear, and enhanced alignment of machinery components.

Efficiency in Postal Sorting Systems

In postal sorting systems, mechanical couplings ensure seamless and efficient operation, reducing the risk of mechanical failures and enhancing throughput.

Reducing Wear and Tear

The use of quality mechanical couplings reduces the wear and tear on components, thereby extending the lifespan of the postal sorting machinery.

Enhancing Alignment

Proper alignment of machinery components is achieved through the use of mechanical couplings, preventing misalignment and associated mechanical issues.

Materials Used in Mechanical Couplings

Mechanical couplings are fabricated from various materials including steel, aluminum, and composite materials, each offering specific properties suitable for different applications.

Steel Couplings

Steel couplings are known for their strength and durability, making them ideal for heavy-duty postal sorting machinery.

Aluminum Couplings

Aluminum couplings are lightweight yet strong, suitable for applications where weight reduction is a priority.

Composite Couplings

Composite couplings offer a combination of strength and flexibility, providing an optimal solution for dynamic postal sorting environments.

Installation and Maintenance

Proper installation and regular maintenance of mechanical couplings are essential to ensure their longevity and optimal performance in postal sorting machinery.

Conclusion

Mechanical couplings are integral to the efficient operation of postal sorting machinery. By carefully selecting the appropriate type and material, postal facilities can ensure reliable and efficient sorting operations.

How does a Mechanical Coupling Work?

A mechanical coupling transmits torque between two connected shafts while accommodating misalignment and reducing shock loads. The coupling¡¯s design and material allow for flexibility and durability, ensuring smooth and efficient operation.

How do I Choose a Mechanical Coupling?

When selecting a mechanical coupling, several parameters and conditions must be considered:

- Load Capacity: Understand the maximum torque and load the coupling will need to handle to avoid mechanical failure.

- Misalignment Tolerance: Determine the degree of angular, parallel, and axial misalignment the coupling can accommodate.

- Environmental Conditions: Consider the operating environment, including temperature, humidity, and exposure to chemicals.

- Material Compatibility: Choose materials that are compatible with the operating conditions and that can withstand the required load and speed.

- Maintenance Requirements: Evaluate the ease of installation and maintenance to minimize downtime and ensure long-term reliability.

What are the Classification of Couplings in Mechanical Engineering?

Mechanical couplings can be classified into several types based on their design and application:

- Rigid Couplings: Used where precise alignment is necessary and no flexibility is required.

- Flexible Couplings: Designed to accommodate misalignment and absorb shock loads.

- Fluid Couplings: Utilize hydraulic fluid to transmit torque, providing smooth operation especially in variable speed applications.

- Universal Joints: Allow for angular misalignment and are commonly used in shafts that transmit rotary motion.

- Oldham Couplings: Suitable for applications needing parallel misalignment, providing a simple and effective solution.

HZPT, located in Hangzhou, Zhejiang, is a modern enterprise integrating R&D, learning, production, and foreign trade. We adhere to our core values of “integrity” as our business philosophy, and we are united, enterprising, and innovative. We are focused on the research and innovation of coupling products, integrating high-tech development, international trade, industrial investment, and domestic and foreign networks. Our business spans Asia, Europe, Africa, and North America, moving towards the vision of becoming a globally influential international group. Our company specializes in producing various series of couplings including drum-shaped couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system, with our own technical development and testing department. We hold certifications such as CQC, ISO, and CE. We provide excellent sales services and technical support to our customers. Serving hundreds of cooperative enterprises, we uphold the business philosophy of “people-oriented, customer first,” working closely with customers for mutual development.

We professionally produce and sell mechanical couplings. Here are five key advantages of our products and company:

- High-Quality Materials: We use premium materials to ensure the durability and reliability of our couplings, reducing maintenance costs.

- Advanced Technology: Our products are developed using cutting-edge technology, providing superior performance and efficiency.

- Custom Solutions: We offer customized coupling solutions tailored to meet the specific needs of each client, ensuring optimal compatibility and performance.

- Global Reach: Our extensive international trade network allows us to serve customers worldwide, ensuring timely delivery and excellent support.

- Comprehensive Quality Management: Our rigorous quality management system ensures that each product meets the highest standards, providing peace of mind to our clients.

We invite you to collaborate with us for high-quality mechanical coupling solutions. Our expertise, technology, and dedication to customer satisfaction make us the ideal partner for your needs.