Mechanical Coupling for Tar Sands Extraction

Introduction to Tar Sands Extraction

Tar sands, also known as oil sands, are a combination of clay, sand, water, and bitumen. The extraction of bitumen from tar sands is a complex process that involves various mechanical systems.

The Role of Mechanical Couplings

Mechanical couplings are integral to the machinery used in tar sands extraction. They ensure the transfer of torque between different components of the machinery, maintaining operational efficiency.

Types of Mechanical Couplings

There are several types of mechanical couplings used in tar sands extraction, including rigid couplings, flexible couplings, and fluid couplings. Each type has its specific application and benefits.

Rigid Couplings in Tar Sands Machinery

Rigid couplings are used in applications where precise alignment is crucial. They are typically employed in machinery where misalignment is minimal and a solid connection is required.

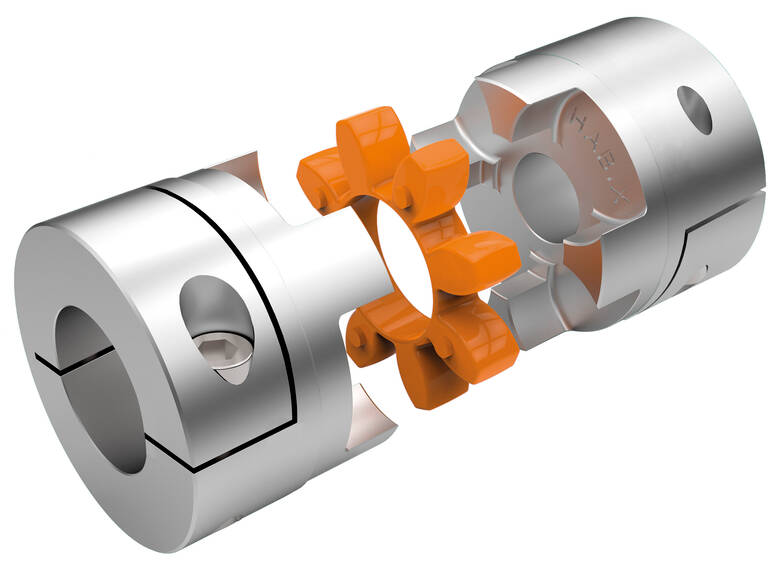

Flexible Couplings for Adaptability

Flexible couplings are designed to accommodate misalignment and provide flexibility in the connection between shafts. They are essential in machines that undergo significant movement and vibration.

Fluid Couplings and Hydraulic Systems

Fluid couplings use hydraulic fluid to transmit power. They are used in heavy machinery to provide smooth and controlled torque transfer, reducing shock loads and wear.

Advantages of Using Mechanical Couplings

Mechanical couplings provide several advantages, including torque transfer efficiency, shock absorption, and accommodation of misalignment. These benefits are critical in maintaining the reliability and longevity of tar sands extraction machinery.

Challenges in Tar Sands Extraction

Extracting bitumen from tar sands poses several challenges, such as dealing with abrasive materials, high temperatures, and the need for continuous operation. Mechanical couplings help mitigate these challenges by providing robust and reliable connections.

Material Selection for Couplings

Choosing the right material for mechanical couplings is essential. Materials must withstand harsh conditions and resist wear and corrosion. Common materials include steel, cast iron, and advanced composites.

Maintenance of Mechanical Couplings

Regular maintenance of mechanical couplings is crucial for ensuring the longevity and efficiency of extraction machinery. This includes lubrication, inspection for wear, and timely replacement of worn components.

Impact on Operational Efficiency

Mechanical couplings directly impact the operational efficiency of tar sands extraction machinery. Properly selected and maintained couplings ensure smooth operation and reduce downtime.

Environmental Considerations

Minimizing environmental impact is a key concern in tar sands extraction. Mechanical couplings, by ensuring efficient machinery operation, help reduce energy consumption and emissions.

Innovations in Coupling Technology

Recent innovations in coupling technology, such as the development of smart couplings with built-in sensors, have further enhanced the reliability and efficiency of tar sands extraction machinery.

Future Trends in Mechanical Couplings

Future trends in mechanical couplings include the use of advanced materials and the integration of IoT technology for real-time monitoring and predictive maintenance.

Conclusion

Mechanical couplings play a vital role in the efficient and reliable operation of tar sands extraction machinery. By ensuring proper torque transfer and accommodating misalignment, they help overcome the challenges of tar sands extraction.

How does a mechanical coupling work?

A mechanical coupling works by connecting two shafts together to ensure the transfer of torque from one to the other. This connection can be rigid or flexible, depending on the type of coupling used. The design ensures that the power generated by the motor is effectively transmitted to the driven equipment, allowing for controlled and efficient operation.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling involves considering several parameters and actual conditions. These include:

- Torque Requirements: The coupling must handle the maximum torque generated by the machinery. Incorrect torque rating can lead to coupling failure.

- Misalignment Tolerance: Depending on the machinery’s setup, the coupling must accommodate angular, parallel, or axial misalignment.

- Environmental Conditions: Consider factors such as temperature, humidity, and the presence of corrosive substances to select appropriate materials for the coupling.

- Speed of Operation: The coupling should be capable of operating at the desired speed without generating excessive noise or heat.

- Maintenance Requirements: Some couplings require regular maintenance, while others are designed for low-maintenance operation.

What are the classification of couplings in mechanical engineering?

Couplings in mechanical engineering can be classified into several categories:

- Rigid Couplings: These provide a solid connection between shafts with no allowance for misalignment.

- Flexible Couplings: Designed to accommodate misalignment and absorb shock loads. Types include jaw couplings, disc couplings, and elastomeric couplings.

- Fluid Couplings: Use hydraulic fluid to transmit torque, providing smooth and controlled power transfer.

- Magnetic Couplings: Utilize magnetic fields to transmit torque, allowing for contactless power transfer and reduced wear.

- Universal Joints: Allow for the transmission of torque between shafts that are not in a straight line.

HZPT, located in Hangzhou, Zhejiang, is a modern company integrating R&D, education, production, and foreign trade. We uphold the core value of “integrity” as our business philosophy, united, enterprising, and innovative. We focus on high-tech development, international trade, industrial investment, and domestic and international networks, dedicated to the research and innovation of coupling products. Our business spans Asia, Europe, Africa, and North America, moving towards the vision of becoming a globally influential international group. Our company specializes in manufacturing a series of coupling products, including gear couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system, our own technology development, and testing departments, and hold CQC, ISO, CE certificates. We can provide excellent sales service and technical support to our customers. Serving hundreds of cooperative enterprises, we adhere to the business philosophy of “people-oriented, customer first,” cooperating sincerely with customers for mutual development.

We specialize in producing and selling mechanical couplings. Here are some of our advantages:

- High-Quality Products: Our couplings are made from premium materials, ensuring durability and reliable performance even under harsh conditions.

- Advanced Technology: We employ state-of-the-art manufacturing processes and innovative technologies to deliver cutting-edge coupling solutions.

- Comprehensive Support: Our dedicated technical support team provides expert guidance and assistance throughout the product’s lifecycle.

- Global Reach: With a strong presence in multiple continents, we can serve customers worldwide, offering timely delivery and localized services.

- Customization Options: We offer customized coupling solutions tailored to meet the specific requirements of different industries and applications.