Mechanical coupling for virtual reality systems

Introduction to Mechanical Coupling

Mechanical coupling is a crucial technology in virtual reality (VR) systems, enabling the precise transfer of mechanical motion and forces. This connection facilitates the immersive experiences that are central to VR.

Importance of Mechanical Coupling in VR Systems

The role of mechanical coupling in VR systems cannot be overstated. It ensures synchronized movements and accurate haptic feedback, providing users with a realistic and engaging experience.

Types of Mechanical Coupling

Various types of mechanical couplings are utilized in VR systems, each serving different functions. These include rigid couplings, flexible couplings, and universal joints, among others.

Applications of Mechanical Coupling in VR

Mechanical coupling finds application in multiple VR components, from motion platforms to haptic controllers. It helps in translating user actions into virtual movements, enhancing interactivity.

Rigid Couplings in VR Systems

Rigid couplings are used to connect two shafts at considerable precision. They are ideal for applications where exact alignment and strong connections are required.

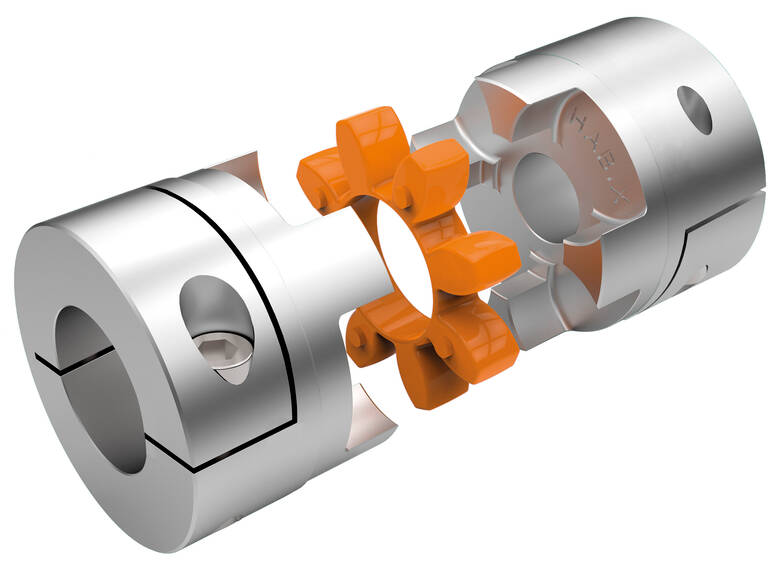

Flexible Couplings for Enhanced Motion

Flexible couplings, such as bellows couplings, allow for slight misalignments and provide flexibility in motion, essential for fluid and realistic VR experiences.

Role of Universal Joints

Universal joints, or U-joints, allow for the transfer of motion between misaligned shafts. They are critical in VR systems that require complex motion paths.

Technological Advancements in Mechanical Coupling

Recent advancements in mechanical coupling technology have significantly improved the performance and reliability of VR systems, enabling more sophisticated and realistic applications.

Challenges in Mechanical Coupling for VR

Despite its advantages, mechanical coupling in VR systems faces challenges such as wear and tear, alignment issues, and the need for regular maintenance.

Future Trends in Mechanical Coupling

The future of mechanical coupling in VR systems looks promising, with ongoing research focusing on more durable materials, advanced designs, and integration with smart technologies.

Integration with Haptic Feedback Systems

Mechanical coupling is integral to haptic feedback systems, providing users with tactile sensations that mimic real-world interactions, thus enhancing the immersive experience.

Impact on User Experience

Effective mechanical coupling significantly impacts user experience in VR, allowing for smoother, more accurate, and responsive interactions within the virtual environment.

Cost-Effectiveness of Mechanical Couplings

Investing in high-quality mechanical couplings can be cost-effective in the long run, reducing maintenance costs and enhancing the longevity and reliability of VR systems.

Case Studies of Mechanical Coupling in VR

Several case studies illustrate the successful implementation of mechanical coupling in VR systems, demonstrating its critical role in delivering high-performance virtual experiences.

Conclusion

Mechanical coupling is an indispensable part of virtual reality systems, providing the necessary physical links that allow for accurate motion and force transfer, ultimately creating a more immersive and realistic VR experience.

How does a mechanical coupling work?

Mechanical coupling works by connecting two rotating shafts, allowing for the transfer of mechanical power and motion. The coupling compensates for misalignment and absorbs shock loads, ensuring smooth and efficient operation.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling requires considering several parameters and actual conditions:

- Torque Requirements: Assess the amount of torque the coupling needs to transmit to avoid overloading or insufficient power transfer.

- Shaft Alignment: Determine the level of misalignment between the shafts to select a coupling that can accommodate the specific alignment needs.

- Operational Speed: Consider the operating speed of the system, as some couplings perform better at high speeds while others are suited for lower speeds.

- Environmental Conditions: Evaluate the working environment, including temperature, humidity, and exposure to chemicals, to choose a coupling material that can withstand these conditions.

- Maintenance Requirements: Consider the ease of maintenance and the frequency of required servicing to ensure long-term reliability and reduced downtime.

What are the classification of couplings in mechanical engineering?

Mechanical couplings are classified into different types based on their design and functionality, including:

- Rigid Couplings: Provide a solid connection between two shafts, ideal for precise alignment and high torque applications.

- Flexible Couplings: Allow for slight misalignments and provide flexibility, reducing stress on the connected components.

- Fluid Couplings: Use hydraulic fluids to transmit power between shafts, offering smooth operation and shock absorption.

- Magnetic Couplings: Utilize magnetic fields to transfer torque without direct contact, ideal for applications requiring hermetic sealing.

- Universal Joints: Allow for the transfer of motion between misaligned shafts, suitable for complex motion paths.

HZPT is located in Hangzhou, Zhejiang Province. It is a modern enterprise integrating R&D, learning, production, and foreign trade. We adhere to our core values and operate with the business philosophy of “integrity.” We are united, enterprising, and innovative. We integrate high-tech development, international trade, industrial investment, and domestic and international networks, focusing on the research and innovation of coupling products. Our business spans Asia, Europe, Africa, and North America, moving towards the vision of becoming a globally influential international group. Our company specializes in producing various coupling products, including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system, our own technology development, and testing department, and hold CQC, ISO, and CE certifications. We provide excellent sales service and technical support to our clients. Serving over a hundred partner enterprises, we adhere to the business philosophy of “people-oriented, customer first,” working sincerely with customers for mutual development. Our company specializes in producing and selling mechanical couplings. Here are several advantages of our products and company:

- High-Quality Products: Our mechanical couplings are made from premium materials and undergo rigorous testing to ensure durability and reliability.

- Innovative Designs: We continuously innovate our product designs to meet the latest industry standards and customer requirements.

- Comprehensive Support: We provide comprehensive technical support and after-sales services to ensure customer satisfaction.

- Global Reach: Our extensive network allows us to serve customers worldwide, offering timely delivery and localized support.

- Certification and Compliance: Our products are certified and comply with international standards, ensuring quality and performance.