Mechanical coupling for zoo equipment

Understanding Mechanical Couplings

Mechanical couplings are essential components in various mechanical systems, including zoo equipment. They serve to connect two shafts together, allowing the transmission of power and torque.

The Importance of Mechanical Couplings in Zoo Equipment

In zoo settings, mechanical couplings are vital for the smooth operation of various equipment such as rotating habitats, feeding mechanisms, and even transportation vehicles used within the zoo premises.

Types of Mechanical Couplings

Mechanical couplings come in a variety of types, each with specific applications and benefits. The choice of coupling depends on the requirements of the zoo equipment and the operational conditions.

Flexible Couplings

Flexible couplings are designed to accommodate slight misalignments between connected shafts. They are ideal for zoo equipment that requires a certain degree of flexibility due to movement or vibration.

Rigid Couplings

Rigid couplings are used when precise alignment is necessary. They provide a solid connection with no allowance for misalignment, making them suitable for stationary zoo equipment.

Elastomeric Couplings

Elastomeric couplings utilize an elastic material to transmit torque, providing vibration damping and shock absorption. These are particularly useful in zoo environments where equipment may be subject to sudden impacts.

Gear Couplings

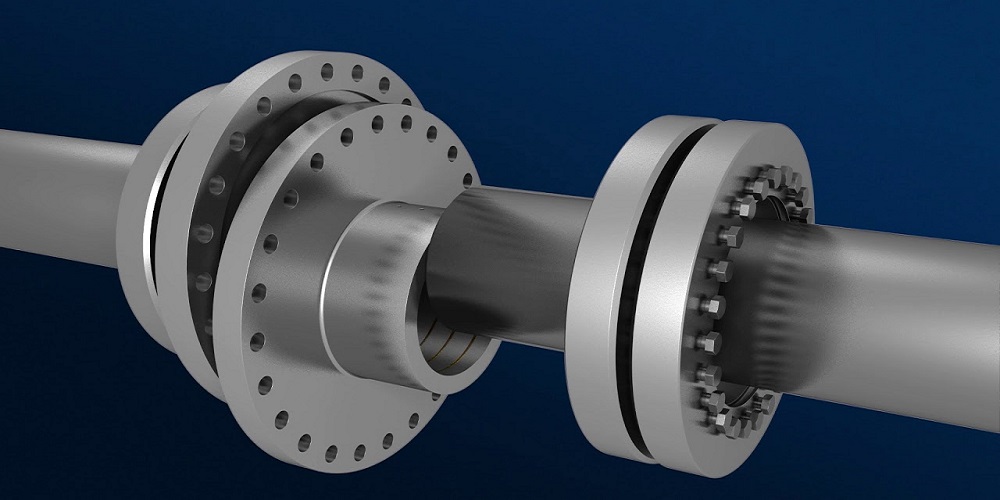

Gear couplings consist of two hubs with external teeth and a sleeve with internal teeth. They are robust and can handle high torque, making them suitable for heavy-duty zoo equipment.

Applications in Zoo Equipment

The use of mechanical couplings in zoo equipment ensures reliability and efficiency. They are used in various applications such as rotating enclosures, feeding mechanisms, and transportation systems within the zoo.

Benefits of Using Mechanical Couplings

Mechanical couplings offer several benefits including reducing downtime, enhancing the lifespan of equipment, and improving the safety and efficiency of zoo operations.

Choosing the Right Coupling

Selecting the appropriate coupling for zoo equipment involves considering factors such as torque requirements, misalignment tolerance, and environmental conditions.

Maintenance and Durability

Regular maintenance of mechanical couplings is crucial to ensure their durability and optimal performance. Proper lubrication and periodic inspections can prevent premature failure.

Environmental Considerations

In a zoo setting, environmental conditions such as humidity, temperature, and exposure to elements must be considered when choosing mechanical couplings to ensure longevity and reliability.

Innovations in Coupling Technology

Advancements in materials and design have led to the development of more efficient and durable mechanical couplings, catering to the specific needs of modern zoo equipment.

Integration with Modern Zoo Systems

Mechanical couplings can be seamlessly integrated into modern zoo systems, enabling automated and remote operations, thereby enhancing the overall efficiency and safety of zoo management.

Conclusion

Mechanical couplings are indispensable in the operation of zoo equipment. Understanding their types, benefits, and applications can significantly improve the efficiency and safety of zoo operations.

How does a mechanical coupling work?

A mechanical coupling works by connecting two shafts together to transmit power and torque. The coupling can accommodate slight misalignments and absorb shocks, ensuring smooth and efficient operation of the connected equipment.

How do I choose a mechanical coupling?

Choosing a mechanical coupling involves considering several factors:

- Torque Requirements: Assess the torque that needs to be transmitted to ensure the coupling can handle the load.

- Misalignment Tolerance: Determine the allowable misalignment between shafts to select a coupling that can accommodate it.

- Environmental Conditions: Consider the operating environment, including temperature, humidity, and exposure to elements.

- Material Compatibility: Ensure the coupling material is compatible with the operational conditions and the equipment.

- Maintenance Requirements: Evaluate the maintenance needs to select a coupling that fits the maintenance schedule and capabilities.

What are the classification of couplings in mechanical engineering?

Couplings in mechanical engineering can be classified into several types including:

- Flexible Couplings: Allow for misalignment between connected shafts.

- Rigid Couplings: Provide a solid connection with no allowance for misalignment.

- Elastomeric Couplings: Use elastic material for vibration damping and shock absorption.

- Gear Couplings: Consist of two hubs with teeth and a sleeve with internal teeth, suitable for high torque applications.

- Fluid Couplings: Use fluid to transmit torque, providing smooth and adjustable operation.

HZPT is located in Hangzhou, Zhejiang Province. We are a modern enterprise integrating research, development, production, and foreign trade. We adhere to our core values of “integrity” as our business philosophy, promoting unity, progress, and innovation. We focus on the research and innovation of coupling products, combining high-tech development, international trade, industrial investment, and domestic and foreign networks. Our business spans Asia, Europe, Africa, and North America, moving towards the vision of becoming a globally influential international group.

Our company specializes in the production of drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system, and we have our own technology development and testing departments. We hold certificates such as CQC, ISO, and CE. We provide excellent sales service and technical support to our customers.

Serving hundreds of cooperative enterprises, we adhere to the business philosophy of “people-oriented, customer first,” working sincerely with customers for mutual development. Our mechanical couplings offer several advantages:

- High Durability: Our products are made from high-quality materials, ensuring long-lasting performance and reliability.

- Advanced Technology: We incorporate the latest technological advancements in our couplings, providing superior performance and efficiency.

- Custom Solutions: We offer customized coupling solutions to meet the specific needs of our clients.

- Global Reach: Our extensive network allows us to supply our products worldwide, ensuring timely delivery and support.

- Comprehensive Support: We provide full technical support and after-sales service, ensuring seamless integration and operation of our couplings.