Mechanical Coupling for Canning Machinery

The Importance of Mechanical Coupling in Canning Machinery

Mechanical coupling plays a crucial role in the seamless operation of canning machinery. These components ensure the efficient transmission of torque and power from one part of the machine to another. As a result, they directly impact the productivity and reliability of canning processes.

Types of Mechanical Couplings Used in Canning Machinery

There are various types of mechanical couplings suited for different applications in canning machinery. Understanding the specific types and their advantages helps in choosing the right coupling for your needs.

Rigid Couplings

Rigid couplings are used where precise alignment and a rigid connection between two shafts are required. They are ideal for high-torque applications but lack flexibility to accommodate misalignment.

Flexible Couplings

Flexible couplings are designed to accommodate misalignment and absorb shock loads. These couplings are essential in applications where alignment is not perfect, offering enhanced longevity and reliability.

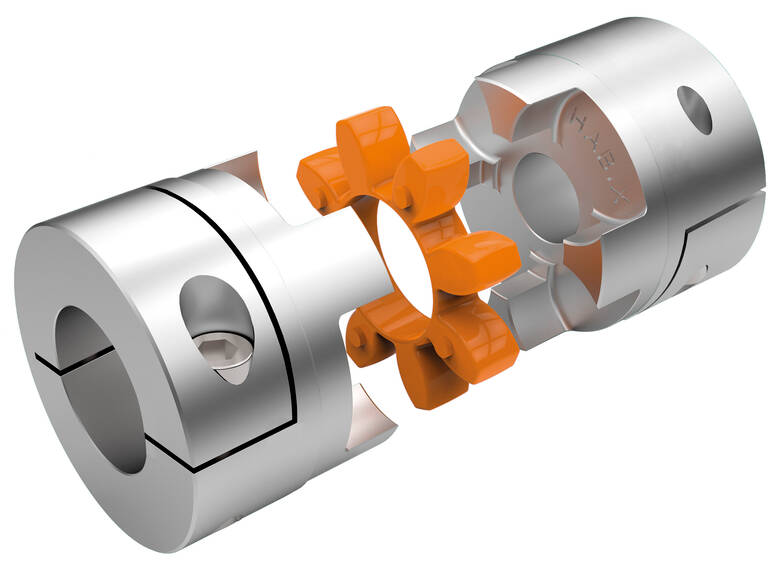

Jaw Couplings

Jaw couplings consist of two hubs with an elastomeric insert. They are widely used due to their simplicity, cost-effectiveness, and ability to handle slight misalignments and vibrations.

Gear Couplings

Gear couplings consist of two hubs with external gear teeth and a sleeve with internal gear teeth. They are known for their high torque capacity and ability to accommodate angular misalignment.

Grid Couplings

Grid couplings use a grid spring to transmit torque while accommodating misalignment and dampening vibrations. They are suitable for high-torque applications and provide excellent shock absorption.

Disc Couplings

Disc couplings feature a series of thin metal discs to transmit torque, offering a combination of high precision, low maintenance, and the ability to handle misalignment.

The Role of Couplings in Canning Line Efficiency

Couplings are integral to the overall efficiency of a canning line. Proper selection and maintenance of couplings can significantly reduce downtime and increase throughput.

Common Issues with Mechanical Couplings

Despite their robustness, mechanical couplings can face issues like wear, misalignment, and fatigue. Regular inspections and timely replacements are essential to prevent breakdowns.

Maintenance Tips for Mechanical Couplings

Routine maintenance includes checking for signs of wear, ensuring proper alignment, and lubricating moving parts. These practices extend the lifecycle of couplings and maintain operational efficiency.

Innovations in Coupling Technology

Advancements in materials and design have led to the development of couplings with higher efficiency, better alignment tolerance, and reduced maintenance requirements.

Environmental Considerations in Coupling Selection

Choosing the right coupling also involves considering the environmental conditions in which it will operate, such as temperature, humidity, and exposure to chemicals.

Cost-Benefit Analysis of Couplings

Performing a cost-benefit analysis helps in selecting a coupling that offers the best value for money while meeting the specific needs of the canning machinery.

Future Trends in Mechanical Couplings

The future of mechanical couplings in canning machinery looks promising, with ongoing research focused on enhancing performance, durability, and sustainability.

How Does a Mechanical Coupling Work?

A mechanical coupling connects two shafts to transmit torque and power while accommodating misalignment. It consists of two hubs attached to the shafts and an element that transmits the torque.

How Do I Choose a Mechanical Coupling?

- Torque Requirements: Determine the torque that needs to be transmitted to ensure the coupling can handle the load without failure.

- Misalignment Tolerance: Assess the expected misalignment between shafts and choose a coupling that can accommodate it.

- Speed of Operation: Consider the operating speed to ensure the coupling can perform efficiently without excessive wear.

- Environmental Factors: Evaluate the operating environment, including temperature, humidity, and exposure to chemicals, to select a suitable material.

- Maintenance Needs: Factor in the ease of maintenance and the expected service life of the coupling.

What Are the Classification of Couplings in Mechanical Engineering?

Mechanical couplings are classified into several types based on their construction and function:

- Rigid Couplings: Provide a solid connection between shafts, ideal for precise alignment.

- Flexible Couplings: Allow for misalignment and absorb shock loads, enhancing system reliability.

- Fluid Couplings: Use fluid to transmit torque, offering smooth operation and soft start capabilities.

- Magnetic Couplings: Transfer torque without physical contact, ideal for applications requiring hermetic sealing.

HZPT: Your Trusted Partner for Mechanical Couplings

HZPT is located in Hangzhou, Zhejiang province, and is a modern enterprise integrating R&D, learning, production, and foreign trade. We adhere to our core values with “integrity” as our business philosophy, and we strive for unity, progress, and innovation. We focus on the research and innovation of coupling products, with a presence in Asia, Europe, Africa, and North America, and aiming to become a globally influential international group.

Our company specializes in manufacturing a range of coupling products including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system and our own technology development and testing department, boasting certifications such as CQC, ISO, and CE. We provide excellent sales service and technical support to our customers. Serving over a hundred partner companies, we uphold the principle of “people-oriented, customer first” for mutual cooperation and development.

Why Choose Our Mechanical Couplings?

- High-Quality Materials: We use premium materials to ensure durability and performance in demanding applications.

- Advanced Technology: Our couplings are designed using cutting-edge technology, offering superior efficiency and reliability.

- Customization Options: We provide tailored solutions to meet the specific needs of our clients, ensuring optimal performance.

- Global Reach: With a network spanning multiple continents, we offer timely delivery and support to international customers.

- Comprehensive Support: Our dedicated team offers extensive technical support and after-sales service to ensure customer satisfaction.