Mechanical Coupling for Park Maintenance Equipment

Introduction to Mechanical Coupling

Mechanical coupling is an indispensable component in various machinery. This article delves into its significance in the realm of park maintenance equipment, providing detailed insights and practical applications.

What is Mechanical Coupling?

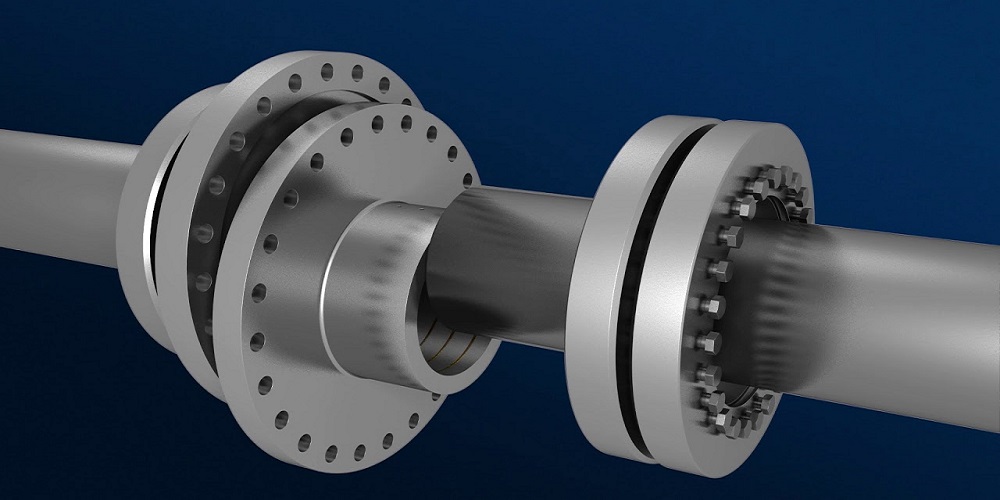

Mechanical coupling refers to the device that connects two shafts together at their ends for the purpose of transmitting power. It ensures that the machinery operates efficiently, reducing wear and tear.

Types of Mechanical Couplings

There are several types of mechanical couplings, each designed to serve specific purposes. Common types include rigid couplings, flexible couplings, and fluid couplings.

Importance in Park Maintenance Equipment

In park maintenance equipment, mechanical couplings play a critical role in ensuring the machinery operates smoothly and efficiently, leading to well-maintained parks.

Benefits of Using Mechanical Couplings

Using mechanical couplings in park maintenance equipment offers numerous benefits such as enhanced performance, reduced maintenance costs, and increased lifespan of the equipment.

Challenges in Mechanical Couplings

While mechanical couplings are beneficial, they also present certain challenges including misalignment, wear and tear, and the need for regular maintenance.

Innovations in Mechanical Coupling Technology

The field of mechanical couplings has seen significant innovations, including the development of high-performance materials and advanced designs to improve efficiency and durability.

Installation of Mechanical Couplings

Proper installation of mechanical couplings is crucial for optimal performance. It involves precise alignment and secure fastening to prevent operational disruptions.

Maintenance of Mechanical Couplings

Regular maintenance of mechanical couplings is essential to ensure longevity and reliability. This includes lubrication, inspection, and replacement of worn-out parts.

Common Applications in Park Maintenance

Mechanical couplings are commonly used in various park maintenance equipment such as lawn mowers, leaf blowers, and irrigation systems.

Case Studies and Real-World Examples

Several case studies highlight the effectiveness of mechanical couplings in park maintenance equipment, showcasing improved performance and reduced downtime.

Future Trends in Mechanical Couplings

The future of mechanical couplings looks promising with ongoing research and development focusing on enhancing their capabilities and integrating smart technologies.

Choosing the Right Mechanical Coupling

Selecting the right mechanical coupling is critical for achieving optimal performance. Factors to consider include the type of machinery, operational conditions, and specific requirements.

Environmental Impact

Mechanical couplings contribute to sustainability by enhancing the efficiency of machinery, reducing energy consumption, and minimizing environmental impact.

Conclusion

Mechanical couplings are vital components in park maintenance equipment, providing numerous benefits and ensuring the machinery operates efficiently. Understanding their importance and proper maintenance can lead to better-maintained parks and sustainable practices.

How does a mechanical coupling work?

A mechanical coupling works by connecting two rotating shafts to transmit torque and rotational motion. It aligns the shafts, compensates for misalignment, and absorbs shock and vibration to ensure smooth operation.

How do I choose a mechanical coupling?

When choosing a mechanical coupling, consider the following parameters and actual conditions:

- Torque Requirements: Determine the torque that the coupling needs to transmit to ensure it can handle the load.

- Shaft Sizes: Ensure the coupling is compatible with the shaft diameters of the connected machinery.

- Operating Conditions: Consider the operational environment, including temperature, humidity, and exposure to chemicals.

- Misalignment Tolerance: Choose a coupling that can compensate for the expected misalignment between shafts.

- Maintenance Requirements: Select a coupling that aligns with your maintenance capabilities and schedules.

What are the classification of couplings in mechanical engineering?

Mechanical couplings are classified into several categories based on their functionality and design. These include:

- Rigid Couplings: These couplings are used when precise alignment is required and there is no allowance for misalignment.

- Flexible Couplings: These allow for some misalignment and flexibility, making them suitable for applications with varying conditions.

- Fluid Couplings: These use fluid to transmit torque and provide smooth operation with shock absorption capabilities.

- Universal Joints: These are used in applications requiring angular motion and can handle significant misalignment.

- Gear Couplings: These are suitable for high-torque applications and can accommodate some misalignment.

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, manufacturing, production, and international trade. We adhere to our core values of “integrity” as our business philosophy, embracing unity, progress, and innovation. We focus on the research and innovation of coupling products, with our business extending across Asia, Europe, Africa, and North America, aiming to become an internationally influential conglomerate. Our product range includes drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star-shaped couplings, expansion couplings, diaphragm couplings, tire couplings, and more. We have a complete and scientific quality management system and our own technology development and testing departments, certified by CQC, ISO, CE, etc. We provide excellent sales service and technical support to hundreds of partner companies, adhering to the business philosophy of ¡°people-oriented, customer first,¡± collaborating sincerely with customers for mutual development. We specialize in the production and sale of mechanical couplings. Below are some of our advantages:

- High-Quality Materials: We use only the finest materials to ensure the durability and reliability of our products.

- Advanced Manufacturing Techniques: Our state-of-the-art manufacturing processes guarantee precision and consistency.

- Comprehensive Quality Control: Our rigorous quality control measures ensure that every product meets the highest standards.

- Innovative Designs: Our R&D team continually innovates to provide the most efficient and effective coupling solutions.

- Global Reach: Our extensive distribution network ensures timely delivery and support worldwide.

We invite you to partner with us and experience the superior quality and service that HZPT offers.