Mechanical Coupling for Data Storage Systems

Importance of Mechanical Coupling in Data Storage

Mechanical coupling plays a pivotal role in ensuring the reliability and efficiency of data storage systems. By seamlessly connecting various components, it facilitates stable and secure data transfer with minimal latency.

Types of Mechanical Couplings

Various types of mechanical couplings are employed in data storage systems, each with distinct characteristics and applications. Common types include flexible couplings, rigid couplings, and fluid couplings.

Flexibility in System Design

Flexible couplings allow for a degree of misalignment between connected components, which is crucial in dynamic systems where precision alignment can be challenging to maintain.

Maintaining System Integrity

Mechanical couplings help maintain system integrity by absorbing shocks and vibrations. This ensures that sensitive data storage components are protected from mechanical stresses.

Enhancing Data Transfer Efficiency

By minimizing mechanical losses and ensuring smooth power transmission, mechanical couplings enhance the overall efficiency of data transfer within storage systems.

Role in Reducing Downtime

Efficient mechanical couplings reduce the likelihood of system failures, thereby minimizing downtime and enhancing the reliability of data storage systems.

Durability and Longevity

High-quality mechanical couplings are designed to withstand the rigors of continuous operation, ensuring the durability and longevity of data storage systems.

Customization for Specific Requirements

Mechanical couplings can be customized to meet specific requirements of data storage systems, providing tailored solutions for diverse operational environments.

Ensuring Compatibility

Compatibility between different components is crucial for the optimal performance of data storage systems. Mechanical couplings ensure seamless integration of various parts.

Cost-Effectiveness

Investing in high-quality mechanical couplings can be cost-effective in the long run, as they reduce maintenance costs and extend the lifespan of data storage systems.

Applications in Various Industries

Mechanical couplings are used in a variety of industries, including data centers, telecommunications, and cloud storage, proving their versatility and essential role in modern technology.

Advanced Materials and Technologies

Utilization of advanced materials and cutting-edge technologies in the manufacturing of mechanical couplings enhances their performance and reliability in data storage systems.

Environmental Considerations

Environmentally friendly mechanical couplings are designed to minimize energy consumption and reduce the carbon footprint of data storage systems.

Future Trends in Mechanical Couplings

Innovations in mechanical coupling technologies are paving the way for more efficient and robust data storage systems, with a focus on automation and smart integration.

Conclusion

Mechanical couplings are indispensable components of data storage systems, ensuring their reliability, efficiency, and longevity. By understanding their importance and applications, we can optimize the performance of these critical systems.

How does a mechanical coupling work?

Mechanical coupling works by connecting two rotating shafts together, allowing for the transmission of torque and rotational motion. This connection can accommodate misalignment, absorb shocks, and minimize vibration, thereby ensuring smooth and efficient operation of the connected machinery.

How do I choose a mechanical coupling?

When choosing a mechanical coupling, consider the following parameters and conditions:

- Torque Requirements: Determine the torque that needs to be transmitted. This helps in selecting a coupling that can handle the load without failure.

- Misalignment: Evaluate the permissible misalignment between the connected shafts. Choose a coupling that can accommodate angular, parallel, and axial misalignments.

- Operating Environment: Consider environmental factors such as temperature, humidity, and exposure to chemicals. Select a coupling made from materials that can withstand these conditions.

- Speed: Assess the operating speed of the machinery. High-speed applications require couplings designed to operate smoothly at such velocities.

- Maintenance: Opt for couplings that require minimal maintenance and are easy to install and replace, reducing downtime and operational costs.

What are the classification of couplings in mechanical engineering?

Couplings in mechanical engineering can be classified into several categories, including:

- Rigid Couplings: Provide a solid connection between shafts with no allowance for misalignment, suitable for precise alignment applications.

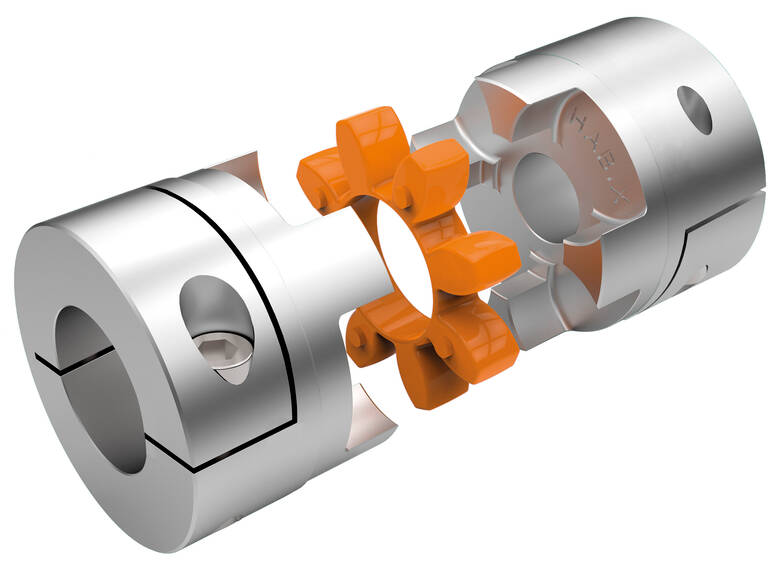

- Flexible Couplings: Allow for some degree of misalignment and provide vibration damping, ideal for dynamic systems.

- Fluid Couplings: Use hydraulic fluid to transmit torque, suitable for smooth and gradual power transmission.

- Elastomeric Couplings: Incorporate elastic materials to absorb shock and vibration, offering flexibility and damping characteristics.

- Magnetic Couplings: Utilize magnetic fields to transmit torque without physical contact, suitable for hermetically sealed systems.

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, learning, production, and foreign trade. We adhere to our core values and operate with integrity, striving for unity, progress, and innovation. We focus on the research and innovation of coupling products, with our business extending across Asia, Europe, Africa, and North America, moving towards becoming an internationally influential group.

Our company specializes in producing a wide range of couplings, including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We boast a complete and scientific quality management system and have our own technology development and testing departments. We hold certifications such as CQC, ISO, and CE.

We provide excellent sales services and technical support to our customers. Serving hundreds of cooperative enterprises, we adhere to the business philosophy of “people-oriented, customer first,” working sincerely with our clients for mutual development.

Why Choose Our Mechanical Couplings?

We offer a superior range of mechanical couplings designed to meet the diverse needs of our clients. Here are five key advantages of our products and company:

- Quality Assurance: Our products undergo rigorous quality checks to ensure they meet international standards, providing reliability and safety in various applications.

- Innovative Design: We employ advanced technologies and innovative designs to develop couplings that offer superior performance and efficiency.

- Customization: We offer tailored solutions to meet the specific requirements of our clients, ensuring optimal compatibility and performance in their systems.

- Global Reach: With a strong presence in multiple continents, we are well-equipped to serve customers worldwide, providing timely support and delivery.

- Technical Expertise: Our team of experienced engineers and technicians is dedicated to providing expert advice and support, helping our clients achieve their operational goals.