Mechanical coupling for drone delivery systems

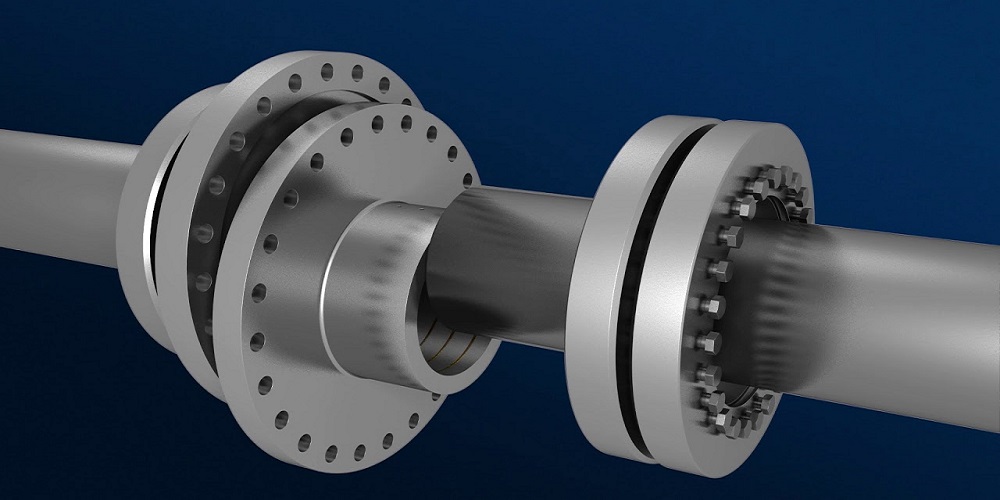

Introduction to Mechanical Coupling

Mechanical coupling is a critical component in drone delivery systems, enabling efficient transmission of power between mechanical parts. This article delves into the nuances of mechanical coupling and its significance in drone technology.

The Role of Mechanical Coupling in Drone Delivery

In drone delivery systems, mechanical couplings facilitate the transfer of rotational power from motors to propellers, ensuring smooth and efficient flight operations. They maintain alignment and balance, crucial for stable drone navigation.

Types of Mechanical Couplings

Mechanical couplings come in various forms, each designed for specific applications. Common types include rigid, flexible, and fluid couplings, each offering unique benefits for drone delivery systems.

Rigid Couplings

Rigid couplings are utilized in scenarios where precise alignment is necessary. They provide a solid connection between shafts, ensuring accurate power transmission without any play or backlash.

Flexible Couplings

Flexible couplings are essential in absorbing misalignments and vibrations, enhancing the durability and longevity of drone components. They are ideal for applications where slight misalignment is inevitable.

Fluid Couplings

Fluid couplings use hydraulic fluid to transmit power, offering a smooth and controlled transfer of energy. This type is particularly useful in drones requiring variable speed control.

Advantages of Mechanical Couplings in Drone Systems

Mechanical couplings bring several advantages to drone delivery systems, including improved efficiency, reduced maintenance, and enhanced performance. They ensure reliable operation even under varying loads.

Materials Used in Mechanical Couplings

The choice of materials for mechanical couplings impacts their performance and durability. Common materials include steel, aluminum, and composite materials, each chosen based on the specific application requirements.

Design Considerations for Drone Couplings

When designing couplings for drones, factors such as weight, size, and load capacity must be considered. Lightweight materials and compact designs are preferred to minimize the overall weight of the drone.

Challenges in Implementing Mechanical Couplings

Implementing mechanical couplings in drone systems presents challenges like ensuring precise alignment, managing wear and tear, and optimizing for different environmental conditions.

Innovations in Coupling Technology

Recent advancements in materials science and engineering have led to the development of more durable and efficient couplings. Innovations like smart couplings with built-in sensors are paving the way for enhanced drone performance.

Applications of Mechanical Couplings Beyond Drones

While this article focuses on drone delivery systems, it’s worth noting that mechanical couplings are widely used in various industries, including automotive, aerospace, and manufacturing.

Future Trends in Drone Couplings

The future of mechanical couplings in drone delivery systems looks promising, with trends pointing towards more lightweight, efficient, and intelligent coupling solutions that can adapt to dynamic flight conditions.

Conclusion

Mechanical coupling is a cornerstone of modern drone delivery systems, offering numerous benefits in terms of performance, reliability, and efficiency. As technology progresses, we can expect even more innovative coupling solutions to emerge.

How does a mechanical coupling work?

A mechanical coupling connects two shafts together, allowing the transfer of torque and rotation. It compensates for misalignments and mitigates the effects of vibrations and shocks, ensuring smooth and efficient power transmission.

How do I choose a mechanical coupling?

Choosing a mechanical coupling requires careful consideration of several parameters and conditions:

1. **Torque Requirements**: Determine the torque to be transmitted and select a coupling that can handle the load.

2. **Speed**: Ensure the coupling can operate efficiently at the required rotational speed.

3. **Misalignment**: Consider the types and degrees of misalignment (angular, axial, and radial) that the coupling must accommodate.

4. **Environmental Conditions**: Assess the operating environment for factors like temperature, humidity, and exposure to chemicals.

5. **Material Compatibility**: Choose coupling materials that are compatible with the application’s environmental and load conditions.

What are the classification of couplings in mechanical engineering?

Mechanical couplings are classified based on their design and functionality:

1. **Rigid Couplings**: Provide a solid connection with no flexibility.

2. **Flexible Couplings**: Allow some degree of misalignment and absorb shocks and vibrations.

3. **Fluid Couplings**: Use hydraulic fluid for smooth torque transmission.

4. **Universal Couplings**: Allow for angular misalignment between shafts.

5. **Diaphragm Couplings**: Use a flexible diaphragm to transmit torque while accommodating misalignment.

HZPT: Innovating Mechanical Couplings for the Future

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, production, and international trade. We uphold core values of integrity, unity, progress, and innovation. Our focus on high-tech development, international trade, and industrial investment has positioned us as leaders in coupling product research and innovation.

Our product range includes drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We boast a comprehensive, scientific quality management system and have our development and testing departments with certifications like CQC, ISO, and CE.

Our advantages include:

1. **Cutting-Edge Technology**: We use the latest technology in our production processes, ensuring high-quality and reliable coupling products.

2. **Global Reach**: Our business spans Asia, Europe, Africa, and North America, aiming to become a globally influential international group.

3. **Comprehensive Product Range**: We offer a wide selection of mechanical couplings to meet diverse industrial needs.

4. **Quality Assurance**: Our products undergo stringent quality checks and comply with international standards.

5. **Customer-Centric Approach**: We provide excellent sales service and technical support, ensuring customer satisfaction and fostering long-term partnerships.