Mechanical Coupling for Courier Service Equipment

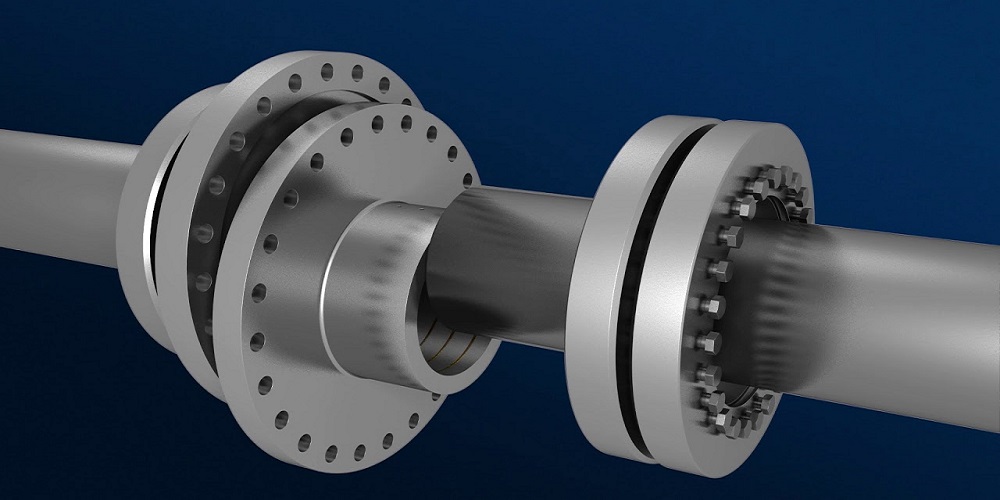

Introduction to Mechanical Couplings

Mechanical couplings are essential components in courier service equipment, providing the necessary connection and power transmission between different mechanical parts. Understanding their functionality and applications can significantly enhance the efficiency and reliability of courier systems.

The Role of Mechanical Couplings in Courier Systems

Mechanical couplings play a crucial role in ensuring smooth and efficient power transmission within courier service equipment. They help to connect moving parts while accommodating misalignment and reducing mechanical wear, thus extending the lifespan of the machinery.

Types of Mechanical Couplings

There are various types of mechanical couplings used in courier service equipment, including rigid couplings, flexible couplings, and fluid couplings. Each type has its specific application and benefits, making them suitable for different operational requirements.

Rigid Couplings

Rigid couplings are used in applications where precise alignment and minimal flexibility are required. They provide a solid connection between shafts, ensuring accurate power transmission without any backlash or slippage.

Flexible Couplings

Flexible couplings are designed to accommodate misalignment and absorb shock loads. They are ideal for systems where slight deviations in alignment can occur, providing a durable and reliable connection between components.

Fluid Couplings

Fluid couplings utilize hydraulic fluid to transmit power between shafts. They offer smooth and controlled power transmission, making them suitable for applications requiring gradual acceleration and deceleration.

Advantages of Using Mechanical Couplings

Mechanical couplings provide numerous advantages, including improved power transmission efficiency, reduced mechanical wear, and enhanced operational reliability. They also help to minimize downtime and maintenance costs.

Materials Used in Mechanical Couplings

Mechanical couplings are typically made from robust materials such as steel, aluminum, and high-strength alloys. These materials ensure durability and reliability, even under harsh operating conditions.

Design Considerations for Mechanical Couplings

When designing mechanical couplings, factors such as load capacity, alignment tolerance, and operational environment must be considered. Proper design ensures optimal performance and longevity of the coupling.

Installation and Maintenance of Mechanical Couplings

Correct installation and regular maintenance are crucial for the effective functioning of mechanical couplings. Proper alignment and lubrication can prevent premature wear and extend the service life of the coupling.

Applications of Mechanical Couplings in Courier Services

Mechanical couplings are used in various courier service equipment, including conveyor systems, sorting machines, and packaging units. They ensure smooth and reliable operation, enhancing the overall efficiency of the courier service.

Innovation in Mechanical Couplings

Recent advancements in materials and manufacturing techniques have led to the development of high-performance mechanical couplings. Innovations such as composite materials and precision machining have improved the performance and reliability of couplings.

Challenges in Mechanical Coupling Implementation

Implementing mechanical couplings in courier service equipment can pose challenges such as alignment issues, load variability, and environmental factors. Addressing these challenges requires careful planning and design optimization.

Future Trends in Mechanical Couplings

The future of mechanical couplings lies in the integration of smart technologies and advanced materials. Innovations such as condition monitoring and self-lubricating materials are expected to revolutionize the coupling industry.

Conclusion

Mechanical couplings are indispensable components in courier service equipment, ensuring efficient and reliable power transmission. By understanding their types, applications, and maintenance requirements, businesses can optimize their operations and enhance service quality.

How does a mechanical coupling work?

A mechanical coupling works by connecting two shafts and transmitting rotational power from one to the other. The coupling accommodates misalignment and absorbs shock loads, ensuring smooth and efficient power transmission. The design of the coupling determines its ability to handle specific loads, speeds, and operating conditions.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling involves considering several key parameters and actual conditions:

- Torque Requirements: Determine the torque that needs to be transmitted to ensure the coupling can handle the required load.

- Alignment Tolerance: Assess the degree of misalignment the coupling can accommodate without compromising performance.

- Operational Speed: Consider the operating speed of the machinery to select a coupling that can handle the required RPM.

- Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and exposure to chemicals, to choose a suitable material.

- Maintenance Needs: Consider the maintenance requirements and ease of installation to ensure long-term reliability and cost-effectiveness.

What are the classification of couplings in mechanical engineering?

Mechanical couplings can be classified into several categories based on their design and application:

- Rigid Couplings: Provide a solid connection with no flexibility, used in precise alignment applications.

- Flexible Couplings: Accommodate misalignment and absorb shock loads, suitable for dynamic applications.

- Fluid Couplings: Utilize hydraulic fluid for smooth power transmission, ideal for controlled acceleration.

- Gear Couplings: Use intermeshing gears to transmit torque, providing high torque capacity.

- Diaphragm Couplings: Use flexible metal diaphragms to handle misalignment, offering high precision and reliability.

HZPT: A Leader in Mechanical Couplings

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, learning, production, and foreign trade. We adhere to the company’s core values and business philosophy of “integrity,” unity, progress, and innovation.

We specialize in the research and innovation of coupling products, including drum couplings, spring pin couplings, serpentine spring couplings, universal joints, star couplings, expansion couplings, diaphragm couplings, and tire couplings. Our products are compliant with CQC, ISO, and CE standards, ensuring top-notch quality and performance.

Why Choose Our Mechanical Couplings?

Here are the key advantages of our products and company:

- High-Quality Materials: We use top-grade materials to ensure durability and reliability under various operating conditions.

- Advanced Manufacturing: Our state-of-the-art manufacturing processes guarantee precision and consistency in every coupling we produce.

- Comprehensive Quality Control: Our rigorous quality management system ensures that each product meets the highest standards.

- Innovative Solutions: We continually invest in R&D to develop innovative coupling solutions that meet evolving industry needs.

- Global Reach: Our extensive international network enables us to serve clients across Asia, Europe, Africa, and North America, providing excellent customer support and technical assistance.

With our commitment to excellence and customer-centric approach, we invite you to collaborate with us to enhance your operational efficiency and reliability.