Mechanical Coupling for Disaster Relief Equipment

Introduction to Mechanical Couplings

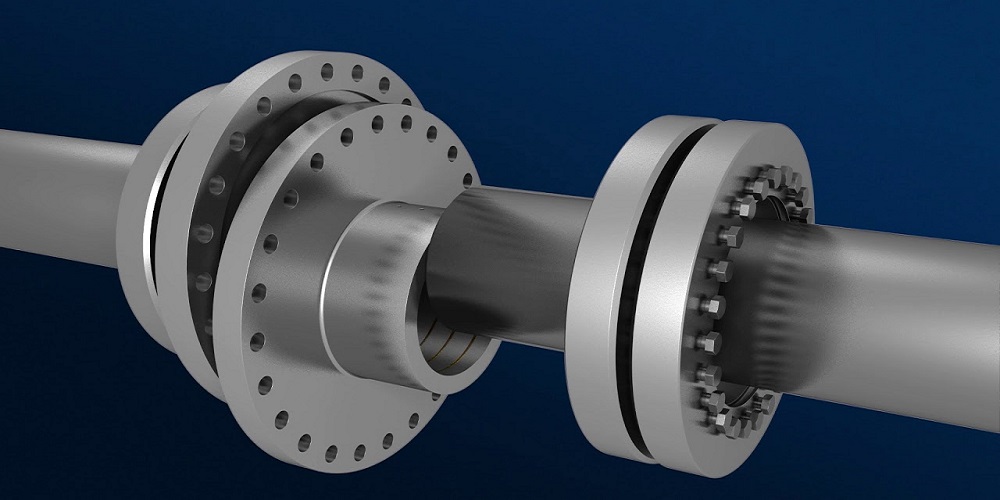

Mechanical couplings are critical components in disaster relief equipment. They ensure the seamless transmission of power between different machinery parts, improving efficiency and reliability during operations.

The Importance of Mechanical Couplings in Disaster Relief

In disaster relief scenarios, equipment must perform under extreme conditions. Mechanical couplings provide the necessary durability and adaptability, enabling machines to function optimally amidst challenging environments.

Types of Mechanical Couplings Used in Disaster Relief Equipment

Different types of mechanical couplings are utilized in disaster relief equipment, each tailored to specific operational needs. This includes rigid couplings, flexible couplings, and universal joints.

Rigid Couplings

Rigid couplings are used where precise alignment is crucial. They offer a solid connection that ensures the equipment components remain in perfect sync, preventing any misalignment.

Flexible Couplings

Flexible couplings absorb shocks and vibrations. Their elasticity allows for slight misalignments, which is vital in unpredictable disaster environments.

Universal Joints

Universal joints enable angular misalignment between connected shafts. This flexibility is essential for equipment that needs to operate in rugged and uneven terrains.

Advantages of Using Mechanical Couplings

Mechanical couplings offer several advantages, including enhanced power transmission, reduced maintenance costs, and improved operational safety.

Enhanced Power Transmission

Couplings ensure efficient power transfer from engines to operational parts, maximizing the performance of disaster relief machinery.

Reduced Maintenance Costs

By absorbing shocks and accommodating misalignments, mechanical couplings reduce wear and tear on machinery, leading to lower maintenance costs.

Improved Operational Safety

Mechanical couplings contribute to safer equipment operations. They minimize the risk of mechanical failures that could compromise relief efforts.

Key Features to Consider When Selecting Mechanical Couplings

Selecting the right mechanical coupling involves considering factors such as load capacity, alignment, and environmental conditions.

Load Capacity

The coupling must handle the maximum load of the equipment without compromising performance. It’s crucial to assess the torque requirements of the machinery.

Alignment Capability

Proper alignment is essential for efficient power transmission. Couplings should accommodate any potential shaft misalignments.

Environmental Durability

Disaster relief environments can be harsh. Couplings must resist corrosion, extreme temperatures, and other environmental stresses.

Innovations in Mechanical Coupling Technology

Recent advancements in coupling technology have led to more robust and reliable designs, incorporating materials and engineering techniques that enhance performance.

How Mechanical Couplings Enhance Disaster Relief Operations

By ensuring reliable power transmission, mechanical couplings help disaster relief equipment operate smoothly, which is critical for timely and effective disaster response.

Conclusion

Mechanical couplings are indispensable in disaster relief equipment. Their ability to transmit power efficiently and withstand harsh conditions ensures that relief operations can proceed without interruptions.

How does a mechanical coupling work?

Mechanical couplings function by joining two rotating shafts, allowing power to be transmitted from one to the other. This connection can be rigid or flexible, depending on the type of coupling used. The primary principle behind mechanical couplings is to ensure that the shafts remain aligned and capable of transmitting torque without slippage. This is achieved through various design features, such as interlocking teeth, flexible elements, or rigid structures that maintain the alignment of the shafts.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling requires careful consideration of several parameters and actual conditions:

- Torque Requirements: Assess the maximum torque the coupling needs to transmit to ensure it can handle the load without failure.

- Misalignment Accommodation: Determine how much angular, radial, or axial misalignment the coupling needs to accommodate, which affects the choice between rigid and flexible couplings.

- Environmental Conditions: Consider the operating environment, including factors like temperature, humidity, and exposure to corrosive elements, to select a coupling with appropriate durability.

- Size and Space Constraints: Ensure the coupling fits within the available space and meets the size requirements of the equipment.

- Maintenance and Service Life: Evaluate the maintenance needs and expected service life of the coupling to minimize downtime and maximize operational efficiency.

What are the classification of couplings in mechanical engineering?

Mechanical couplings are classified into several types based on their design and function:

- Rigid Couplings: Provide a solid connection between shafts. Used when precise alignment is crucial.

- Flexible Couplings: Allow for slight misalignments and absorb shocks. Ideal for applications with variable loads.

- Universal Joints: Enable angular misalignment between shafts. Suitable for complex motion paths.

- Diaphragm Couplings: Use a flexible diaphragm to transmit torque. Commonly used in high-speed applications.

- Gear Couplings: Consist of two gears that mesh together, allowing for slight misalignments and high torque transmission.

About HZPT

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, learning, production, and foreign trade. We adhere to our core values of “integrity” as our business philosophy, uniting, progressing, and innovating. We focus on the research and innovation of coupling products, combining high-tech development, international trade, industrial investment, and domestic and foreign networks. Our business spans Asia, Europe, Africa, and North America, moving towards the vision of becoming a globally influential international group.

We specialize in producing gear couplings, spring pin couplings, serpentine spring couplings, universal joints, star couplings, expansion couplings, diaphragm couplings, and tire couplings. Our comprehensive and scientific quality management system includes our own technology development and testing department, holding certifications like CQC, ISO, and CE. We provide excellent sales service and technical support to over 100 cooperative enterprises, adhering to the business philosophy of “people-oriented, customer first,” cooperating sincerely with customers, and developing together.

Why Choose Our Mechanical Couplings?

- High Quality and Reliability: Our couplings are manufactured to the highest standards, ensuring superior performance and durability.

- Innovative Designs: We continuously innovate our products to meet the evolving needs of our customers, incorporating the latest technologies and materials.

- Comprehensive Support: We offer extensive technical support and customer service to ensure our clients get the most out of our products.

- Global Presence: With a strong presence in multiple continents, we can meet the needs of clients worldwide.

- Certifications and Compliance: Our products comply with international standards, holding certifications like CQC, ISO, and CE, ensuring quality and safety.