Mechanical Coupling for Customs Inspection Systems

Introduction to Mechanical Coupling

Mechanical coupling serves as a vital component in customs inspection systems. It facilitates the transfer of mechanical power between two shafts, ensuring synchronous operation and precise alignment.

The Role of Mechanical Coupling in Customs Inspection

Mechanical coupling plays a critical role in customs inspection systems by enhancing the efficiency and reliability of the equipment used. It ensures that all mechanical movements are accurately synchronized, which is essential for the precise inspection of goods.

Types of Mechanical Couplings

In the realm of mechanical engineering, various types of couplings are used, each suited to specific applications and operational requirements.

Rigid Couplings

Rigid couplings are used when precise shaft alignment is required. They provide a solid connection between two shafts, ensuring no relative motion between them.

Flexible Couplings

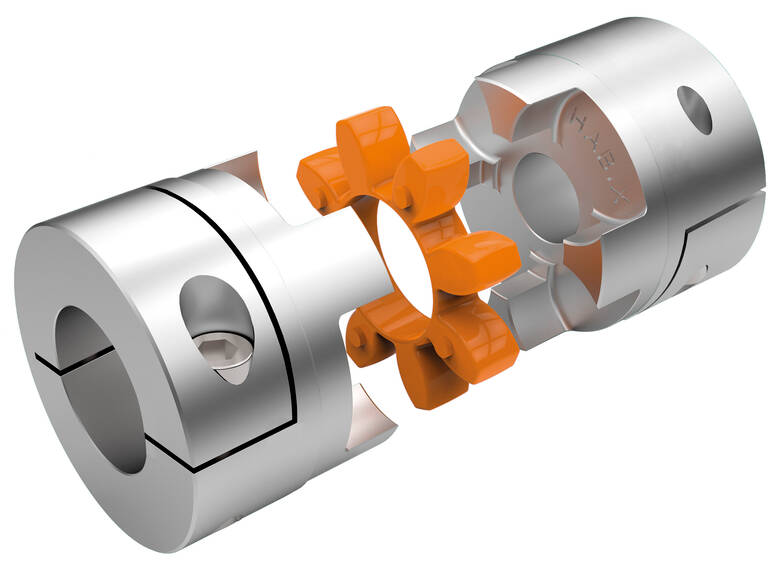

Flexible couplings accommodate misalignment between shafts while transmitting torque. They are ideal for systems where minor shaft misalignments are unavoidable.

Fluid Couplings

Fluid couplings use hydraulic fluid to transfer torque, providing smooth and controlled power transmission, which is particularly useful in systems requiring variable speed control.

Advantages of Using Mechanical Couplings

Mechanical couplings offer several advantages, including improved power transmission efficiency, reduced maintenance requirements, and extended equipment lifespan.

Customization and Adaptability

One of the significant benefits of mechanical couplings is their ability to be customized and adapted to specific needs, making them suitable for various customs inspection systems.

Durability and Reliability

Mechanical couplings are designed to withstand harsh operating conditions, providing durability and reliability over extended periods, which is essential for continuous customs inspection operations.

Installation and Maintenance

Installing and maintaining mechanical couplings is straightforward, requiring minimal downtime, which is crucial for maintaining the smooth operation of customs inspection systems.

Technological Advancements in Mechanical Couplings

Recent technological advancements have led to the development of more efficient and robust mechanical couplings, significantly enhancing the performance of customs inspection systems.

Case Studies and Applications

Numerous case studies have demonstrated the effectiveness of mechanical couplings in customs inspection systems, highlighting their role in improving operational efficiency and accuracy.

Future Trends in Mechanical Couplings

Future trends in mechanical couplings are focused on further improving efficiency, adaptability, and integration with advanced inspection technologies.

Conclusion

Mechanical couplings are indispensable in customs inspection systems, offering numerous benefits that enhance the overall performance and reliability of the inspection process.

How Does a Mechanical Coupling Work?

A mechanical coupling works by connecting two shafts together, allowing them to rotate in unison while transferring torque from one shaft to the other. This connection can be rigid or flexible, depending on the type of coupling used. The coupling ensures that the mechanical power is efficiently transmitted between the shafts, preventing slippage and misalignment.

How Do I Choose a Mechanical Coupling?

Choosing the right mechanical coupling involves considering several parameters and practical conditions:

- Torque Requirements: Determine the torque that needs to be transmitted to ensure the coupling can handle the load without failure.

- Shaft Size and Alignment: Consider the size and alignment of the shafts to select a coupling that fits well and accommodates any misalignment.

- Operating Environment: Evaluate the environmental conditions such as temperature, humidity, and exposure to chemicals to choose a coupling material that can withstand these factors.

- Speed of Operation: Consider the operational speed to ensure the coupling can operate efficiently at the required speeds without causing vibration or noise.

- Maintenance Requirements: Assess the ease of maintenance and the frequency of required servicing to select a coupling that minimizes downtime and maintenance costs.

What Are the Classification of Couplings in Mechanical Engineering?

In mechanical engineering, couplings are classified based on their functionality and design:

- Rigid Couplings: These provide a solid connection with no flexibility, used in applications requiring precise alignment.

- Flexible Couplings: These allow for some degree of misalignment and absorb shock loads, suitable for applications with minor alignment issues.

- Fluid Couplings: These use hydraulic fluids to transmit torque, providing smooth and controlled power transmission.

- Elastomeric Couplings: These utilize elastic materials to absorb shocks and vibrations, ideal for applications with variable loads and misalignments.

- Gear Couplings: These feature toothed gears that transmit torque, allowing for some misalignment and high torque transmission capabilities.

HZPT: Your Trusted Partner for Mechanical Couplings

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, production, and international trade. We adhere to our core values of “integrity” and our business philosophy of unity, progress, and innovation. We specialize in the research and innovation of coupling products and our business spans Asia, Europe, Africa, and North America.

Why Choose HZPT?

- Extensive Product Range: We manufacture a complete range of coupling products, including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings.

- Advanced Quality Management: Our comprehensive and scientific quality management system ensures that all products meet the highest standards.

- Technical Expertise: We have dedicated R&D and testing departments, enabling us to develop and deliver innovative coupling solutions.

- Certification and Compliance: We hold CQC, ISO, and CE certifications, ensuring our products meet international quality and safety standards.

- Customer-Centric Approach: We provide excellent sales services and technical support, ensuring customer satisfaction and fostering long-term partnerships.

HZPT continues to serve hundreds of cooperative enterprises, adhering to the “people-oriented, customer-first” business philosophy, working together with our clients for mutual development. We invite you to partner with us and experience the superior quality and service that HZPT offers.