Dresser Mechanical Coupling

Introduction to Dresser Mechanical Coupling

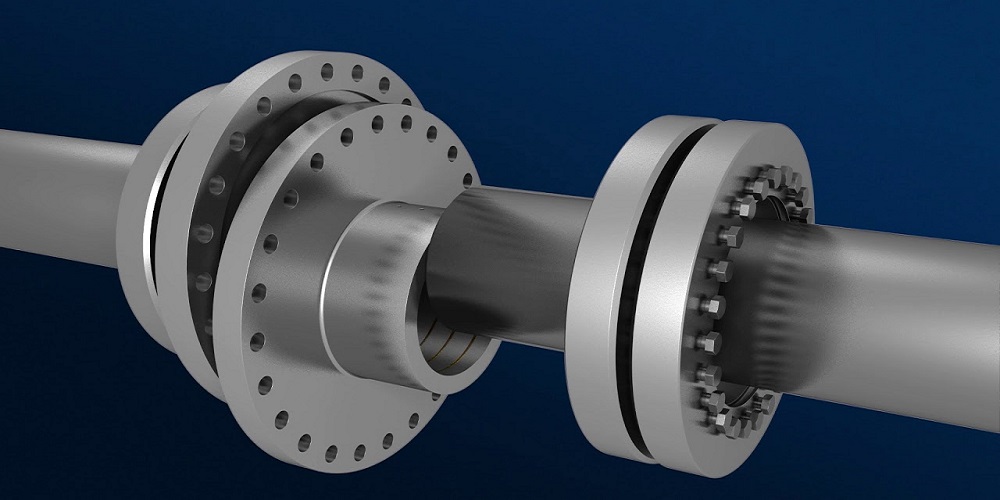

Dresser mechanical coupling is an essential component in the mechanical and engineering industries. Its primary function is to connect two shafts together for the purpose of transmitting power. The coupling accommodates misalignments, reduces shock loads, and compensates for shaft end movements.

History of Dresser Mechanical Couplings

The invention of the Dresser mechanical coupling dates back to the early 20th century. It was designed to provide a robust and flexible solution for shaft coupling applications, becoming a standard in various industrial applications.

Structural Composition

The typical structure of a Dresser mechanical coupling includes metallic elements, elastomeric inserts, and fastening hardware. These components work together to ensure durability and flexibility.

Material Selection

Materials used in Dresser mechanical couplings are often chosen based on the application environment. Common materials include steel, aluminum, and specialized polymers to handle different stress and temperature conditions.

Types of Dresser Mechanical Couplings

There are various types of Dresser mechanical couplings, including rigid, flexible, and torsional couplings. Each type serves specific needs and applications within the mechanical engineering field.

Applications in Different Industries

Dresser mechanical couplings are used across a wide range of industries, such as automotive, aerospace, manufacturing, and energy sectors. Their versatility makes them indispensable in these fields.

Advantages of Using Dresser Mechanical Couplings

The use of Dresser mechanical couplings offers several benefits, including enhanced operational efficiency, reduced maintenance costs, and improved safety. They also provide excellent shock absorption and misalignment correction.

Installation Process

Proper installation of Dresser mechanical couplings is crucial for optimal performance. The process involves aligning the shafts accurately, securing the coupling elements, and ensuring the correct torque settings.

Maintenance and Inspection

Regular maintenance and inspection of Dresser mechanical couplings help in early detection of wear and tear. This ensures prolonged service life and prevents unexpected downtimes.

Common Issues and Troubleshooting

Common issues with Dresser mechanical couplings include misalignment, wear, and imbalance. Troubleshooting these problems involves checking alignment, replacing worn components, and ensuring proper balance.

Innovations in Coupling Technology

Recent innovations in Dresser mechanical couplings include the development of smart couplings that monitor performance in real-time. These innovations help in predictive maintenance and enhance overall system reliability.

Environmental Considerations

The environmental impact of Dresser mechanical couplings is minimal, especially when they are made from recyclable materials. Furthermore, their long service life reduces waste and the need for frequent replacements.

Cost Efficiency

Investing in Dresser mechanical couplings can be cost-effective in the long run. Their robust design and low maintenance requirements lead to significant savings over time.

Future Trends

The future of Dresser mechanical couplings looks promising, with trends pointing towards increased automation, enhanced material science, and the integration of IoT technologies.

Conclusion

Dresser mechanical couplings remain a cornerstone in various mechanical applications. Their versatility, reliability, and cost-effectiveness make them an ideal choice for engineers and industry professionals.

How does a mechanical coupling work?

A mechanical coupling works by connecting two shafts together, allowing them to transmit torque while accommodating misalignments and absorbing vibrations. The coupling consists of two halves, each attached to one of the shafts. These halves are joined by flexible or rigid elements, which enable the transmission of power while mitigating misalignments and shock loads.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling involves considering several parameters and actual conditions:

- Torque Requirements: Determine the amount of torque that needs to be transmitted and select a coupling that can handle this load.

- Speed of Operation: Consider the operational speed at which the coupling will function, as this affects the selection process.

- Misalignment Compensation: Evaluate the degree of misalignment between the shafts. Different couplings offer varying levels of misalignment accommodation.

- Environmental Conditions: Assess the operating environment, including temperature, humidity, and exposure to chemicals, to select materials that will withstand these conditions.

- Installation and Maintenance: Consider the ease of installation and maintenance requirements to ensure long-term reliability and cost efficiency.

What are the classification of couplings in mechanical engineering?

Mechanical couplings can be classified into several categories:

- Rigid Couplings: These couplings provide a solid connection between two shafts, ideal for applications where precise alignment is possible.

- Flexible Couplings: These couplings allow for some degree of misalignment, ideal for applications with minor shaft deviations.

- Torsional Couplings: These couplings are designed to absorb torsional vibrations, making them suitable for applications with fluctuating torque conditions.

- Elastic Couplings: These couplings use elastic materials to provide flexibility and shock absorption, suitable for high-vibration environments.

- Fluid Couplings: These use a fluid medium to transmit torque, ideal for applications requiring smooth power transmission.

HZPT: Your Trusted Mechanical Coupling Expert

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, learning, production, and foreign trade. We adhere to our core values of “integrity,” and our business philosophy of unity, progress, and innovation. We specialize in the research and innovation of coupling products, with our business spanning Asia, Europe, Africa, and North America, aiming to become a globally influential international group. Our product lines include drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, membrane couplings, tire couplings, and more. We have a complete and scientific quality management system, our own technology development, and testing department, and certifications such as CQC, ISO, and CE.

We offer excellent sales services and technical support, serving over a hundred cooperative enterprises with the philosophy of “people-oriented, customer first.” We work closely with our customers for mutual development. We invite you to choose our mechanical couplings and benefit from our industry expertise.

- Wide Range of Products: We provide a comprehensive selection of coupling products to meet various industrial needs.

- Innovative Solutions: Our commitment to R&D ensures we deliver cutting-edge solutions and stay ahead in the market.

- Quality Assurance: Our products undergo rigorous testing and quality checks to ensure they meet the highest standards.

- Global Reach: With a strong international presence, we cater to clients worldwide, ensuring reliable service and support.

- Customer-Centric Approach: We prioritize customer satisfaction and work closely with clients to deliver tailored solutions that meet their specific requirements.