Mechanical Coupling for Particle Accelerators

The Role of Mechanical Coupling in Particle Accelerators

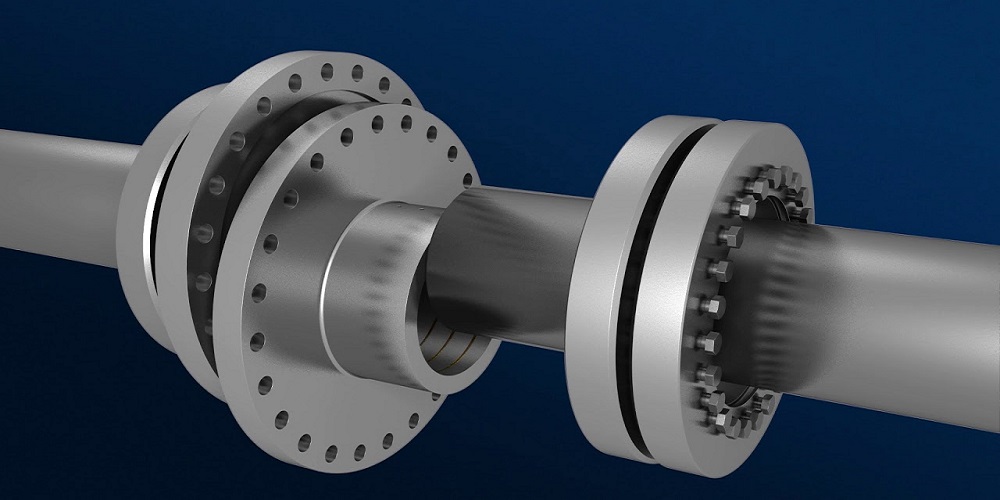

Mechanical couplings are pivotal in the operation of particle accelerators, ensuring the transfer of rotational force without slippage. They maintain the synchronization of mechanical parts, crucial for the precise manipulation of high-energy particles.

Understanding Mechanical Coupling Dynamics

In the intricate framework of particle accelerators, mechanical couplings manage dynamic forces and vibrations. They act as intermediaries that balance torque and angular misalignments, facilitating smooth operation.

Types of Mechanical Couplings Used

Various couplings such as flexible, rigid, and fluid couplings are employed based on the specific requirements of the accelerator. Each type is selected according to its ability to handle torque, misalignment, and operational speed.

Flexible Couplings: Adaptability and Precision

Flexible couplings are designed to accommodate slight misalignments and axial movement between connected shafts. They are essential for high-precision applications, minimizing stress on the mechanical components.

Rigid Couplings: Stability and Strength

Rigid couplings provide a solid connection between two shafts, enabling the transfer of maximum torque without any flexibility. They are ideal for applications where precise alignment is necessary.

Fluid Couplings: Smooth Power Transmission

Fluid couplings use hydraulic fluid to transmit power, offering smooth engagement and reduced shock loads. They are beneficial in reducing mechanical wear and extending the lifespan of the machinery.

Material Selection for Mechanical Couplings

The choice of materials, such as steel, aluminum, and composites, impacts the performance and durability of couplings. Each material offers distinct advantages in terms of strength, weight, and resistance to environmental factors.

Key Design Considerations

Designing mechanical couplings involves considering factors like operational load, speed, and environmental conditions. Engineers must ensure that the selected coupling can withstand the specific demands of the particle accelerator.

Importance of Alignment in Coupling Performance

Proper alignment is crucial for the efficient functioning of mechanical couplings. Misalignment can lead to excessive wear, increased vibration, and potential failure of the coupling and connected components.

Maintenance and Reliability

Regular maintenance is vital to ensure the reliability of mechanical couplings in particle accelerators. Lubrication, inspection for wear, and timely replacement of components help in maintaining optimal performance.

Advances in Coupling Technology

Recent advancements in coupling technology include the development of smart couplings that monitor operational parameters in real-time, providing valuable data for predictive maintenance and performance optimization.

Challenges in Mechanical Coupling for Particle Accelerators

One of the main challenges is managing the high rotational speeds and forces involved in particle accelerators. Couplings must be designed to handle these extreme conditions without compromising stability or precision.

Future Trends in Mechanical Coupling

The future of mechanical coupling technology lies in the integration of advanced materials and smart monitoring systems. These innovations aim to enhance efficiency, reliability, and longevity of couplings in high-tech applications.

Case Studies in Particle Accelerator Coupling

Examining real-world applications, such as the Large Hadron Collider, reveals the critical role that mechanical couplings play in achieving groundbreaking discoveries in particle physics.

Conclusion

Mechanical couplings are indispensable components in the realm of particle accelerators. They ensure the seamless transfer of power and precision alignment, enabling the successful operation of these complex machines.

How does a mechanical coupling work?

Mechanical couplings work by connecting two rotating shafts, allowing for the transfer of torque and accommodating misalignments. They ensure that motion is transmitted efficiently between different parts of the machinery, preserving alignment and reducing wear on components.

How do I choose a mechanical coupling?

To choose the right mechanical coupling, you need to consider several parameters and actual conditions:

- Torque Requirements: Assess the amount of torque that needs to be transmitted to ensure the coupling can handle the load without failure.

- Misalignment Tolerance: Determine the degree of angular, parallel, and axial misalignment between the shafts to select a coupling that can accommodate these deviations.

- Operational Speed: Consider the rotational speed of the application to ensure the coupling can operate efficiently at the desired RPM without causing vibrations or noise.

- Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and exposure to chemicals, to choose a coupling material that can withstand these conditions.

- Maintenance Requirements: Look into the maintenance needs of the coupling, such as lubrication and inspection intervals, to ensure it aligns with your maintenance capabilities and schedules.

What are the classification of couplings in mechanical engineering?

In mechanical engineering, couplings are classified into several types based on their design and function:

- Flexible Couplings: These include gear, grid, and elastomeric couplings, which accommodate misalignments and dampen vibrations.

- Rigid Couplings: Such as sleeve or clamp couplings, these provide a solid connection with no flexibility, suitable for precise alignment.

- Fluid Couplings: Using hydraulic fluid to transmit power, they offer smooth engagement and torque limitation.

- Universal Joints: Allow for greater angular movement between connected shafts, essential in applications with significant misalignment.

- Diaphragm Couplings: Use flexible metal discs to transmit torque while accommodating misalignment, often used in high-speed applications.

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, learning, production, and foreign trade. We adhere to the core values of the company, with “integrity” as our business philosophy, unity, progress, and innovation. We integrate high-tech development, international trade, industrial investment, and domestic and foreign networks, focusing on the research and innovation of coupling products. Our business spans Asia, Europe, Africa, and North America, moving towards the vision of becoming an internationally influential group. Our company specializes in producing drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system, our own technical development, and testing department, and we have CQC, ISO, CE, and other certificates. We can provide excellent sales service and technical support to our customers, serving hundreds of cooperative enterprises. We uphold the business philosophy of “people-oriented, customer first,” working sincerely with customers for joint development. Our company specializes in producing and selling mechanical couplings, and we invite you to consider our products for the following reasons:

- High-Quality Standards: Our products meet rigorous international standards, ensuring reliability and longevity in various applications.

- Innovative Technology: We leverage advanced technologies in the design and manufacture of our couplings, enhancing performance and efficiency.

- Comprehensive Support: We provide extensive technical support and after-sales service to assist with installation, maintenance, and troubleshooting.

- Custom Solutions: Our team can develop customized coupling solutions to meet specific operational requirements and challenges.

- Global Reach: With a broad international presence, we offer timely delivery and service to customers around the world.