Mechanical Coupling for Concrete Mixers

Introduction to Mechanical Couplings

Mechanical couplings are essential components in many industrial applications, including concrete mixers. They transmit torque between shafts and compensate for misalignments.

Types of Mechanical Couplings Used in Concrete Mixers

There are various types of mechanical couplings, including rigid couplings, flexible couplings, and fluid couplings, each serving specific purposes in concrete mixers.

Rigid Couplings

Rigid couplings are used where precise alignment is required. They are ideal for situations where shafts are already aligned.

Flexible Couplings

Flexible couplings can accommodate misalignments between connected shafts, reducing the risk of bearing wear and increasing the lifespan of the equipment.

Fluid Couplings

Fluid couplings use hydraulic fluid to transmit torque, providing a smooth transfer of power and reducing shock loads.

The Role of Mechanical Couplings in Concrete Mixers

In concrete mixers, mechanical couplings ensure the efficient transfer of power from the motor to the mixing drum, which is crucial for consistent concrete mixing.

Key Characteristics of a Quality Mechanical Coupling

Durability, reliability, and the ability to handle high torque loads are essential characteristics of quality mechanical couplings in concrete mixers.

Material Selection for Mechanical Couplings

Material selection is critical for mechanical couplings. Common materials include steel, aluminum, and composite materials, depending on the application’s requirements.

Installation and Maintenance of Mechanical Couplings

Proper installation and regular maintenance are vital to ensure the longevity and performance of mechanical couplings.

Advantages of Using Mechanical Couplings

Mechanical couplings offer several advantages, such as improved alignment, torque transmission, and the ability to handle variable loads.

Challenges in Using Mechanical Couplings

While beneficial, mechanical couplings can present challenges such as wear and tear, misalignment issues, and the need for regular maintenance.

Future Trends in Mechanical Coupling Technology

The future of mechanical coupling technology looks promising, with advancements focusing on materials, design improvements, and greater efficiency.

Case Study: Mechanical Couplings in Large-Scale Concrete Mixer Projects

A detailed examination of how mechanical couplings have been successfully implemented in large-scale concrete mixer projects to ensure operational efficiency.

Expert Tips for Selecting the Right Mechanical Coupling

Selecting the right mechanical coupling involves understanding the specific requirements of your application, including torque capacity, alignment needs, and environmental factors.

Conclusion

Mechanical couplings are indispensable in the operation of concrete mixers, providing reliable and efficient power transmission.

How does a mechanical coupling work?

Mechanical couplings connect two shafts to transmit power and accommodate misalignments. They ensure smooth power transmission and reduce the impact of load changes.

How do I choose a mechanical coupling?

When choosing a mechanical coupling, consider the following parameters and conditions:

- Torque Capacity: Ensure the coupling can handle the maximum torque generated by the motor.

- Misalignment Accommodation: Assess how much misalignment the coupling can tolerate.

- Material: Choose a material that suits the environmental conditions and load requirements.

- Size and Weight: Consider the physical dimensions and weight of the coupling in relation to your machinery.

- Maintenance Requirements: Consider the ease of maintenance and availability of replacement parts.

What are the classification of couplings in mechanical engineering?

Couplings in mechanical engineering are classified into several types, including:

- Rigid Couplings: Used where precise shaft alignment is required.

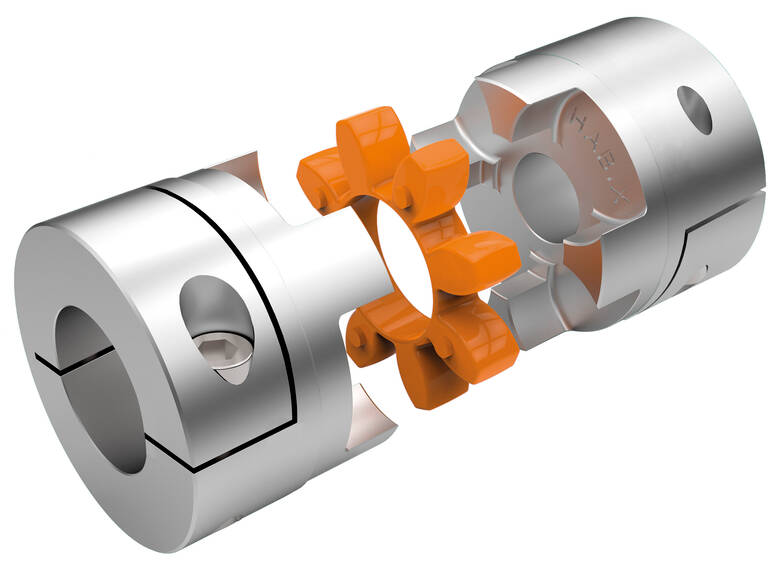

- Flexible Couplings: Accommodate misalignments and reduce vibration.

- Fluid Couplings: Use hydraulic fluid for smooth torque transmission.

- Universal Joints: Provide rotational movement in multiple directions.

- Oldham Couplings: Designed for parallel misalignment and torque transmission.

HZPT: Your Trusted Partner for Mechanical Couplings

HZPT, located in Hangzhou, Zhejiang, is a modern enterprise specializing in the R&D, production, and international trade of mechanical coupling products. We are committed to our core values of integrity and innovation. With high-tech development, international trade, and industrial investment, we focus on coupling products’ research and innovation.

Our business spans Asia, Europe, Africa, and North America, striving to become a globally influential international group. Specialized in producing gear couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings, we are backed by comprehensive quality management systems and our own R&D and testing departments. We hold certifications such as CQC, ISO, and CE.

We offer excellent sales services and technical support to over 100 partner companies, adhering to the philosophy of “people-oriented, customer first.” We collaborate sincerely with customers for mutual development.

Advantages of Choosing Our Products

- High-Quality Materials: Our couplings are made from premium materials, ensuring durability and longevity.

- Advanced Technology: We utilize cutting-edge technology in our manufacturing processes for superior product performance.

- Comprehensive Testing: Each product undergoes rigorous testing to meet international standards.

- Customized Solutions: We provide tailored solutions to meet the unique needs of our customers.

- Global Reach: Our products are trusted by clients worldwide, reflecting our commitment to quality and service.