Mechanical Coupling for Event Staging Equipment

Introduction to Mechanical Coupling

Mechanical couplings are indispensable in the realm of event staging equipment. As integral connectors, they ensure that various components work in unison.

Types of Mechanical Couplings

Mechanical couplings come in diverse forms, each tailored to specific applications. From rigid to flexible, the variety covers a wide spectrum of needs.

Rigid Couplings

Rigid couplings are robust connectors that provide a solid link between two shafts. They are ideal for applications where precise alignment is necessary.

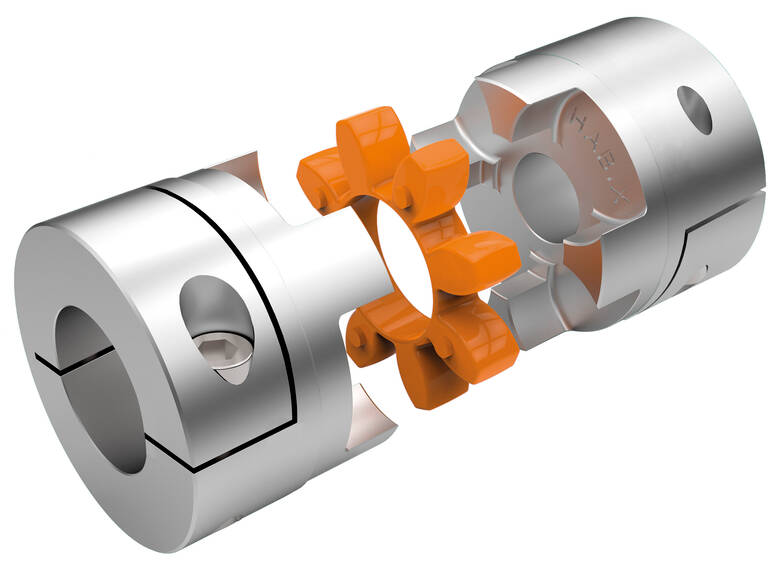

Flexible Couplings

Flexible couplings, on the other hand, accommodate slight misalignments and reduce the transmission of shocks and vibrations.

Applications in Event Staging

In event staging, mechanical couplings play a pivotal role in ensuring seamless operation of lighting rigs, sound systems, and moving platforms.

The Role of Torque Transmission

Torque transmission is a critical function of mechanical couplings. It allows for the efficient transfer of rotational force from one component to another.

Advantages of Using Mechanical Couplings in Staging

Mechanical couplings offer numerous advantages, including increased reliability, enhanced flexibility, and improved safety in event staging setups.

Material Considerations

The materials used in mechanical couplings can significantly impact their performance. Common materials include steel, aluminum, and composite materials.

Design and Engineering

The design and engineering of mechanical couplings involve meticulous calculations to ensure optimal performance and longevity.

Installation and Maintenance

Proper installation and maintenance are crucial for the longevity of mechanical couplings. Regular inspections and adjustments can prevent failures.

Innovative Technologies in Couplings

Recent advancements in technology have led to the development of self-aligning and easily adjustable couplings, enhancing their versatility.

Environmental Considerations

Environmental factors such as temperature, humidity, and exposure to corrosive elements must be considered when selecting mechanical couplings.

Customization Options

Many manufacturers offer customization options to tailor mechanical couplings to specific requirements, ensuring optimal performance.

Cost Implications

While the initial cost of high-quality mechanical couplings may be higher, their durability and reliability often justify the investment.

Conclusion

In conclusion, mechanical couplings are vital components in event staging equipment, offering reliability and efficiency in various applications.

How does a mechanical coupling work?

A mechanical coupling works by connecting two rotating shafts, ensuring the transfer of torque and rotational force between them. This linkage can accommodate misalignments and absorb shocks and vibrations, depending on the type of coupling used.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling involves considering several parameters and actual conditions:

- Torque Requirements: Determine the torque that needs to be transmitted to ensure the coupling can handle the load without failure.

- Alignment Tolerance: Evaluate the degree of alignment between shafts. Flexible couplings are preferable for slight misalignments.

- Environmental Conditions: Assess the operating environment, including temperature, humidity, and potential exposure to corrosive substances.

- Material Compatibility: Ensure the materials used in the coupling are compatible with the application to prevent wear and corrosion.

- Installation Space: Consider the available space for installation, as some couplings may require more room than others.

What are the classification of couplings in mechanical engineering?

In mechanical engineering, couplings are classified into several categories:

- Rigid Couplings: These provide a solid connection with no flexibility, ideal for precisely aligned shafts.

- Flexible Couplings: These absorb misalignments and reduce vibrations. Examples include elastomeric and beam couplings.

- Fluid Couplings: Utilized in high-torque applications, these use fluid to transmit power and accommodate misalignments.

- Magnetic Couplings: These use magnetic fields to transmit torque without direct physical contact, useful in hermetic systems.

HZPT Company Overview

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, learning, production, and foreign trade. We adhere to the core values of “integrity” as our business philosophy, promoting unity, progress, and innovation. Combining high-tech development, international trade, industrial investment, and a global network, we focus on the research and innovation of coupling products. Our business spans Asia, Europe, Africa, and North America, moving towards the vision of becoming an international group with global influence. We specialize in producing a variety of coupling products, including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system and our own technology development and testing departments, boasting certifications such as CQC, ISO, and CE. We provide excellent sales services and technical support to numerous cooperative enterprises, upholding the “people-oriented, customer-first” business philosophy, working sincerely with customers for mutual development.

Why Choose HZPT’s Mechanical Couplings?

HZPT¡¯s mechanical couplings stand out in the market due to several key advantages:

- High-Quality Materials: Our couplings are manufactured from premium materials, ensuring durability and longevity even under demanding conditions.

- Advanced Technology: We incorporate cutting-edge technology in our products, providing innovative solutions that enhance performance and reliability.

- Customization Options: We offer extensive customization options, enabling us to meet the unique requirements of diverse applications.

- Global Reach: Our extensive distribution network allows us to serve clients worldwide, ensuring timely delivery and excellent after-sales support.

- Certified Quality: Our products are certified by leading international standards, providing assurance of their quality and safety.