Mechanical Coupling for Cargo Ships

Introduction to Mechanical Couplings

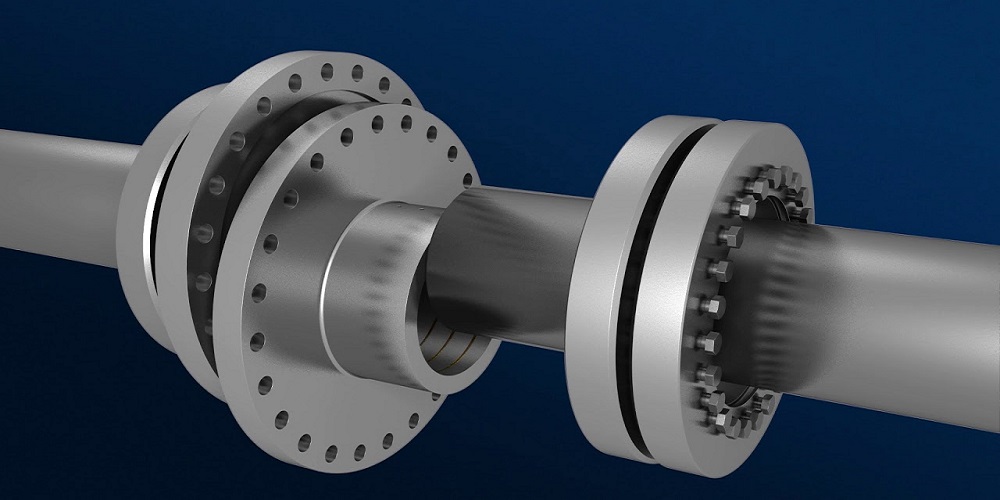

Mechanical couplings are crucial components in the maritime industry. They connect the engine to the propeller shaft, ensuring efficient power transmission.

The Importance of Mechanical Couplings in Cargo Ships

In cargo ships, mechanical couplings play a vital role. They manage the transmission of torque and rotation, ensuring smooth and reliable operations.

Types of Mechanical Couplings

There are several types of mechanical couplings used in cargo ships, each with unique characteristics and applications.

Flexible Couplings

Flexible couplings accommodate misalignments and reduce vibration, enhancing the longevity of mechanical components.

Rigid Couplings

Rigid couplings provide a secure connection between two shafts, ensuring precise alignment and maximum torque transmission.

Fluid Couplings

Fluid couplings use hydraulic fluid to transmit torque, providing smooth acceleration and deceleration, which is essential for large cargo vessels.

Benefits of Using Mechanical Couplings

Mechanical couplings offer numerous benefits, including improved efficiency, reduced maintenance, and extended lifespan of ship components.

Challenges in Mechanical Coupling Design

Designing mechanical couplings for cargo ships involves addressing challenges such as material selection, environmental conditions, and load variations.

Material Selection for Couplings

The choice of materials for mechanical couplings is critical. It must withstand corrosion, extreme temperatures, and high stress.

Environmental Considerations

Couplings must operate reliably in harsh maritime environments, including exposure to saltwater, humidity, and varying temperatures.

Load and Torque Calculations

Accurate load and torque calculations are essential for designing effective mechanical couplings that can handle the operational demands of cargo ships.

Maintenance and Inspection

Regular maintenance and inspection of mechanical couplings are vital. This ensures continued performance and prevents unexpected failures.

Innovations in Coupling Technology

Recent innovations in coupling technology have led to improved performance, efficiency, and reliability in maritime applications.

Case Studies

Examining case studies of mechanical couplings used in cargo ships can provide valuable insights into their performance and application.

Future of Mechanical Couplings in Maritime Industry

The future of mechanical couplings in the maritime industry looks promising, with ongoing advancements in materials and technology.

How Does a Mechanical Coupling Work?

Mechanical couplings work by connecting the engine to the propeller shaft, transmitting torque and rotation through various mechanisms like gears, belts, or hydraulic fluid.

How Do I Choose a Mechanical Coupling?

Choosing the right mechanical coupling involves considering several parameters and actual conditions:

- Torque Capacity: Ensure the coupling can handle the maximum torque of the application without failure.

- Misalignment Accommodation: Determine the type and degree of misalignment that the coupling can tolerate.

- Environmental Conditions: Consider the operating environment, including temperature, humidity, and exposure to corrosive substances.

- Material Compatibility: Choose materials that are compatible with other components to avoid galvanic corrosion.

- Maintenance Requirements: Evaluate the ease of maintenance and the frequency of required inspections.

What are the Classifications of Couplings in Mechanical Engineering?

Mechanical engineering classifies couplings into several categories, including:

- Rigid Couplings: Used where precise alignment is required and there is no allowance for flexibility.

- Flexible Couplings: Allow for some degree of misalignment and are typically used to dampen vibration and noise.

- Fluid Couplings: Utilize hydraulic fluid to transmit torque, providing smooth engagement and disengagement.

- Magnetic Couplings: Use magnetic fields to transmit torque without physical contact, suitable for sterile or explosive environments.

- Oldham Couplings: Consist of three parts and are used to accommodate misalignment between shafts.

HZPT Overview

HZPT is located in Hangzhou, Zhejiang Province, and is a modern enterprise integrating R&D, learning, production, and foreign trade. We uphold our core value of “integrity” as our business philosophy, focusing on teamwork, progress, and innovation. Our company specializes in the development and innovation of coupling products, with a business scope that spans Asia, Europe, Africa, and North America. We are moving towards becoming an international group with global influence.

We specialize in the production of various coupling series including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system and our own technical development and testing department. We hold certifications such as CQC, ISO, and CE, providing excellent sales service and technical support to our customers. Our commitment to “people-oriented, customer first” has led to successful partnerships with over a hundred companies, working together for mutual development.

Why Choose Our Mechanical Couplings?

We recommend our mechanical couplings for several compelling reasons:

- High-Quality Materials: Our couplings are made from premium materials to ensure durability and performance in harsh maritime environments.

- Innovative Designs: We incorporate the latest technological advancements in our coupling designs to enhance efficiency and reliability.

- Custom Solutions: We offer customized coupling solutions tailored to meet the specific needs of our clients.

- Comprehensive Testing: Each coupling undergoes rigorous testing to ensure it meets the highest standards of quality and performance.

- Excellent Customer Support: Our dedicated customer service team provides ongoing support to ensure customer satisfaction and successful operation.