Mechanical coupling for chemical processing

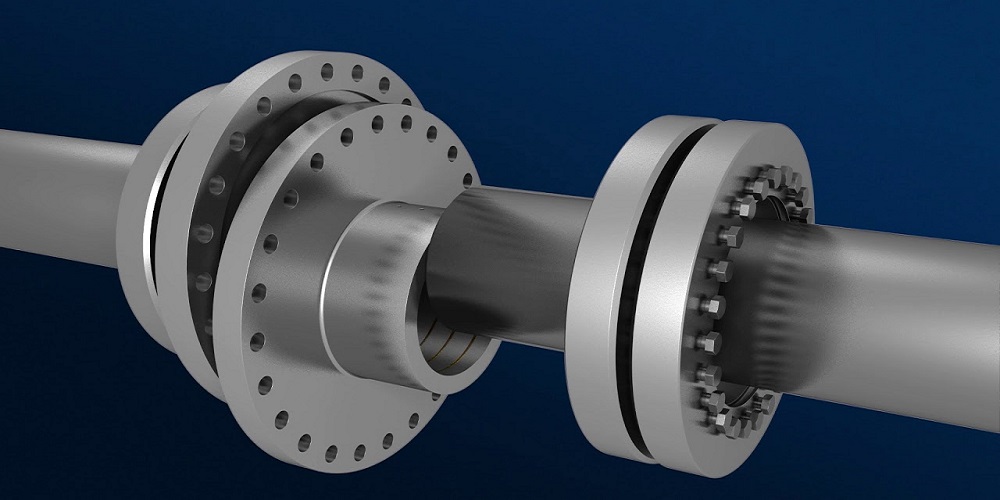

Introduction to Mechanical Coupling

Mechanical coupling is an indispensable component in chemical processing, facilitating the transfer of mechanical power between machinery. This ensures seamless operations, enhanced efficiency, and reduced downtime.

Types of Mechanical Couplings

Understanding the diverse types of mechanical couplings is crucial. From rigid to flexible couplings, each type serves specific applications and has distinct advantages.

Rigid Couplings

Rigid couplings are designed for applications where precise alignment is essential. They offer maximum torque transmission but are intolerant to misalignment.

Flexible Couplings

Flexible couplings accommodate a degree of misalignment between connected shafts. Their design allows for the absorption of shock loads and vibrations.

Importance in Chemical Processing

In chemical processing, precision and reliability are paramount. Mechanical couplings play a vital role in ensuring that machinery operates smoothly, thereby preventing costly interruptions.

Material Selection for Couplings

The choice of material for mechanical couplings in chemical processing environments cannot be understated. Materials must resist corrosion, withstand high temperatures, and endure harsh chemicals.

Stainless Steel Couplings

Stainless steel is a popular choice due to its corrosion resistance and strength, making it suitable for most chemical processing applications.

Composite Couplings

For applications where weight is a concern, composite materials offer a lightweight yet robust alternative, capable of withstanding harsh conditions.

Advantages of Mechanical Couplings

Mechanical couplings offer several benefits, including enhanced operational efficiency, reduced maintenance costs, and increased machinery lifespan.

Advanced Coupling Technologies

Technological advancements have led to the development of smart couplings equipped with sensors that monitor operational parameters in real-time.

Maintenance of Mechanical Couplings

Regular maintenance is essential to ensure the longevity and optimal performance of mechanical couplings. This includes periodic inspections, lubrication, and timely replacements of worn-out components.

Mechanical Coupling Installation

Proper installation is critical to the performance of mechanical couplings. Misalignment or improper fitting can lead to premature failure and inefficiencies.

Applications in Chemical Processing

Mechanical couplings are used in various chemical processing equipment, including pumps, compressors, mixers, and conveyors.

Energy Efficiency

By ensuring precise power transfer and reducing energy losses, mechanical couplings contribute to the overall energy efficiency of chemical processing plants.

Environmental Impact

The use of high-quality, durable couplings can minimize the environmental impact by reducing waste and energy consumption.

Future Trends in Mechanical Couplings

The future of mechanical couplings lies in smart, self-monitoring systems that enhance reliability and efficiency through continuous data analytics and predictive maintenance.

Conclusion

Mechanical couplings are essential for the seamless operation of chemical processing plants. Proper selection, installation, and maintenance will ensure their optimal performance.

How does a mechanical coupling work?

A mechanical coupling connects two rotating shafts, allowing for the transmission of power and torque from one shaft to the other. It can accommodate misalignment and absorb shock loads, ensuring smooth and efficient machinery operation.

How do I choose a mechanical coupling?

Selecting the right mechanical coupling involves considering several parameters and actual conditions:

Torque Requirements

Determine the torque requirements of the application to ensure the coupling can handle the load without failure.

Misalignment Tolerance

Consider the degree of misalignment between the shafts. Flexible couplings are better suited for applications with significant misalignment.

Environmental Conditions

Evaluate the operating environment, including temperature, humidity, and exposure to chemicals, to select a coupling material that can withstand these conditions.

Space Constraints

Assess the available space for the coupling to ensure it fits within the design parameters without causing interference.

Maintenance and Durability

Consider the maintenance requirements and expected lifespan of the coupling. Opt for designs that offer longer service intervals and reduced maintenance costs.

What are the classification of couplings in mechanical engineering?

Mechanical couplings are classified based on their design and function:

Rigid Couplings

Used in applications with precise alignment and no room for misalignment.

Flexible Couplings

Allow for some degree of misalignment and absorb shocks.

Fluid Couplings

Utilize a hydraulic fluid to transmit torque, providing a smooth and controlled power transfer.

Magnetic Couplings

Use magnetic fields to transmit torque without direct physical contact between the shafts.

Universal Joints

Accommodate angular misalignment between shafts, commonly used in automotive applications.

HZPT is located in Hangzhou, Zhejiang Province, and is a modern enterprise integrating R&D, learning, production, and foreign trade. We adhere to our core values, with “integrity” as our business philosophy, fostering unity, progress, and innovation. We are dedicated to the research and innovation of coupling products, combining high-tech development, international trade, industry investment, and domestic and international networks. Our business spans Asia, Europe, Africa, and North America as we strive to become a globally influential international group. Our company specializes in producing gear couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system, our own technical development, and testing departments, with certifications such as CQC, ISO, and CE. We provide excellent sales services and technical support to our customers. Serving hundreds of partner enterprises, we uphold the business philosophy of “people-oriented, customer first,” cooperating sincerely with customers for mutual development.

We specialize in producing and selling mechanical couplings. Our products offer numerous advantages, making them ideal for your applications:

High Performance

Our couplings are designed to deliver optimal performance, ensuring efficient power transmission and reduced downtime.

Durability

Made from high-quality materials, our couplings are built to withstand harsh conditions and provide long-term reliability.

Customization

We offer tailor-made solutions to meet your specific requirements, ensuring the perfect fit for your machinery.

Certification

Our products are certified by CQC, ISO, and CE, ensuring compliance with international quality standards.

Customer Support

We provide unparalleled sales and technical support, assisting you at every step to ensure the success of your projects.

Partner with us to leverage our expertise and enhance the efficiency of your operations.