Mechanical Coupling for Conveyors

Introduction to Mechanical Coupling

Mechanical coupling is an indispensable component in conveyor systems. It facilitates the transfer of rotational power between two shafts, enhancing the efficiency and reliability of the entire system. Understanding its nuances can significantly improve conveyor performance.

The Role of Mechanical Coupling in Conveyors

Mechanical couplings play a pivotal role by ensuring smooth and consistent motion transfer in conveyors. They accommodate misalignment, reduce shock loads, and help in maintaining the synchronization of different sections of the conveyor.

Types of Mechanical Couplings

The market offers a multitude of mechanical couplings, each designed for specific needs. These include rigid couplings, flexible couplings, fluid couplings, and magnetic couplings, each providing unique benefits and limitations.

Rigid Couplings

Rigid couplings provide a permanent connection between two shafts. These are ideal where precise alignment is required and are typically used in applications where shafts are already in alignment.

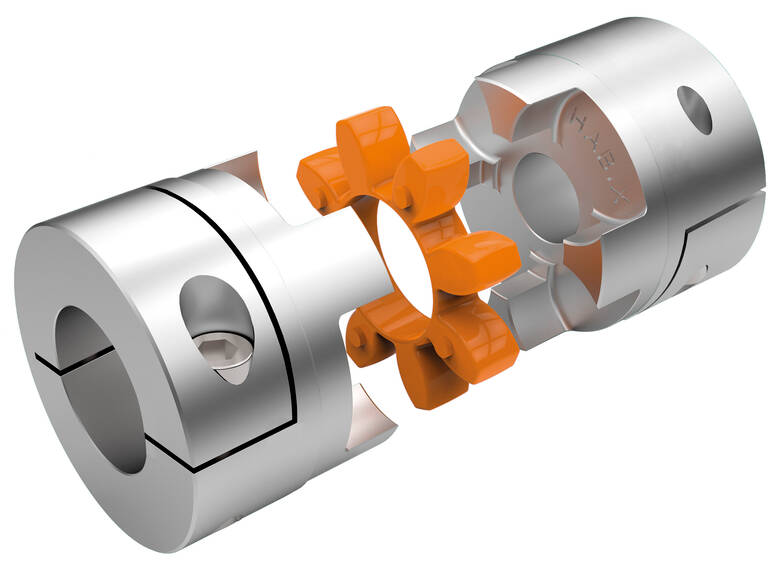

Flexible Couplings

Flexible couplings are designed to accommodate misalignment between coupled shafts. They can absorb shock and vibration, making them suitable for applications where perfect alignment is not feasible.

Fluid Couplings

Fluid couplings use hydraulic fluid to transmit torque between shafts. They provide a smooth start-up and can protect the system from mechanical shock and overload.

Magnetic Couplings

Magnetic couplings use magnetic fields to transfer torque. They offer the advantage of no physical contact between the driving and driven components, reducing wear and tear.

Key Features of Mechanical Couplings

Mechanical couplings are characterized by their ability to transmit torque, accommodate misalignment, absorb shocks, and reduce vibrations. These features make them essential for the efficient operation of conveyor systems.

Design Considerations for Mechanical Couplings

When designing mechanical couplings for conveyors, factors like torque capacity, misalignment tolerance, speed, and environmental conditions must be considered to ensure optimal performance and longevity.

Installation and Maintenance

Proper installation and regular maintenance of mechanical couplings are crucial for the reliable operation of conveyor systems. This includes ensuring correct alignment, lubrication, and periodic inspection.

Common Issues and Troubleshooting

Some common issues with mechanical couplings include misalignment, excessive vibration, and wear. Troubleshooting these problems involves checking alignment, ensuring proper lubrication, and replacing worn components.

Innovations in Mechanical Coupling Technology

Recent advancements in material science and engineering have led to the development of high-performance mechanical couplings that offer improved durability, efficiency, and ease of maintenance.

Applications of Mechanical Couplings in Various Industries

Beyond conveyors, mechanical couplings are used in a variety of industries including automotive, aerospace, manufacturing, and marine, each benefitting from the unique capabilities of different coupling types.

Future Trends in Mechanical Coupling

The future of mechanical coupling technology promises further enhancements in performance, reliability, and versatility, driven by ongoing research and development efforts.

Environmental Impact and Sustainability

Modern mechanical couplings are being designed with sustainability in mind, using eco-friendly materials and processes to reduce their environmental footprint and improve energy efficiency.

Conclusion

Mechanical couplings are vital components in conveyor systems, offering numerous benefits that enhance operational efficiency and reliability. Choosing the right type of coupling is essential for achieving optimal performance.

How does a mechanical coupling work?

A mechanical coupling works by connecting two shafts, allowing them to rotate together while accommodating misalignment and absorbing shock loads. This connection ensures the transfer of rotational power from one shaft to another, facilitating smooth and efficient operation.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling involves considering several parameters and actual conditions:

- Torque Requirements: Determine the torque that needs to be transmitted. Selecting a coupling with the appropriate torque capacity is crucial for ensuring reliable performance.

- Misalignment Tolerance: Assess the level of misalignment between shafts. Choose a coupling that can accommodate the expected misalignment to prevent excessive wear and failure.

- Speed of Operation: Consider the operational speed. High-speed applications may require couplings designed to handle higher rotational speeds without compromising performance.

- Environmental Conditions: Evaluate the working environment, including temperature, humidity, and exposure to chemicals. Select a coupling made from materials that can withstand these conditions.

- Maintenance Requirements: Analyze the maintenance needs. Some couplings require regular maintenance, while others are designed for low-maintenance or maintenance-free operation.

What are the classification of couplings in mechanical engineering?

Mechanical couplings are classified into several categories based on their design and functionality:

- Rigid Couplings: Provide a solid connection but do not accommodate misalignment.

- Flexible Couplings: Can handle angular and parallel misalignment, and reduce shock loads.

- Fluid Couplings: Use fluid to transmit torque, offering smooth start-up and protection against overload.

- Magnetic Couplings: Utilize magnetic fields for torque transfer, eliminating physical contact and wear.

- Universal Joints: Allow for large angular misalignment, suitable for applications with complex shaft configurations.

HZPT Introduction and Product Recommendation

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating research, study, production, and foreign trade. We adhere to our core values and business philosophy of “integrity,” fostering unity, progress, and innovation. Combining high-tech development, international trade, industrial investment, and a domestic and international network, we focus on the research and innovation of coupling products. Our business spans Asia, Europe, Africa, and North America, and we are on the path to becoming a globally influential international group.

We specialize in the production of drum couplings, spring pin couplings, serpentine spring couplings, universal joints, star couplings, expansion couplings, diaphragm couplings, tire couplings, and other series of coupling products. Our company has a complete and scientific quality management system and our own technology development and testing department, holding certifications such as CQC, ISO, and CE. We provide excellent sales services and technical support to over a hundred cooperative enterprises, upholding the business philosophy of “people-oriented, customer foremost,” and fostering sincere cooperation and joint development with customers.

We recommend our mechanical coupling products for the following reasons:

- High-Quality Materials: Our couplings are made from premium materials that ensure durability and reliability in various operational conditions.

- Advanced Technology: We use cutting-edge technology in the design and manufacturing of our couplings, ensuring high performance and efficiency.

- Extensive Range: Our product range includes various types of couplings, catering to different industrial needs and applications.

- Support and Service: We offer comprehensive support and after-sales service, ensuring that our clients get the most out of our products.

- Global Reach: With a presence in multiple continents, we are well-positioned to serve customers worldwide, providing timely and effective solutions.