Mechanical coupling for military vehicles

Introduction to Mechanical Coupling

Mechanical coupling plays a pivotal role in the efficient operation of military vehicles. It ensures the seamless transmission of power and motion between different components. Understanding its myriad applications, benefits, and types is essential for optimizing military vehicle performance.

Historical Context

The evolution of mechanical couplings in military vehicles dates back to early mechanized warfare. Over the decades, advancements in materials science and engineering have significantly enhanced their functionality.

Fundamentals of Mechanical Coupling

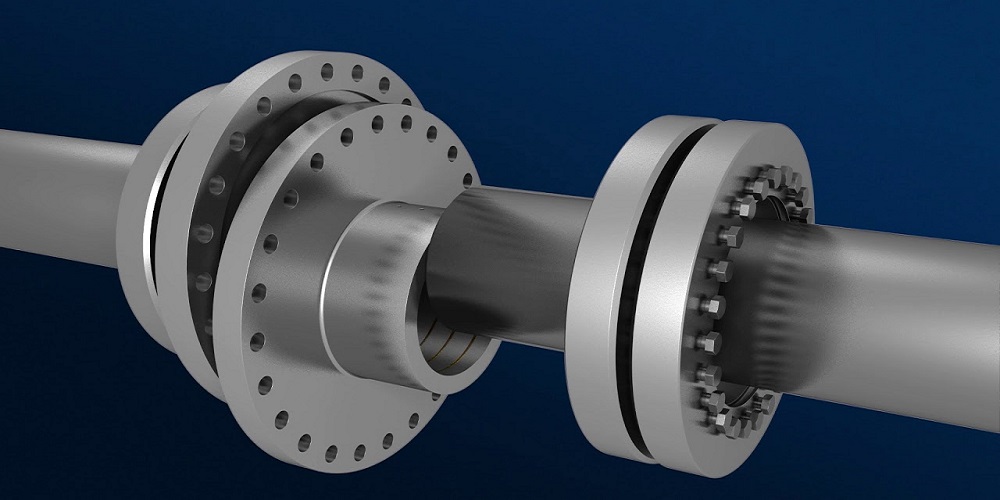

At its core, a mechanical coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power. This connection must accommodate misalignment and vibration, ensuring operational stability.

Types of Couplings Used in Military Vehicles

There are several types of couplings, each with specific advantages suited to different applications. These include rigid couplings, flexible couplings, fluid couplings, and torque-limiting couplings.

Advantages of Mechanical Coupling in Military Applications

Mechanical couplings provide numerous benefits such as improved power transmission efficiency, reduced wear and tear, and enhanced durability under extreme operational conditions.

Challenges in Military Vehicle Coupling

Military vehicles often operate in harsh and unpredictable environments, which can pose significant challenges for mechanical couplings. These include exposure to high temperatures, dirt, and heavy vibrations.

Innovative Materials for Mechanical Couplings

Advancements in materials, such as high-strength alloys and composite materials, have led to the development of more resilient and efficient mechanical couplings suitable for military vehicles.

Design Considerations for Mechanical Couplings

When designing mechanical couplings for military vehicles, factors such as load capacity, alignment tolerance, and environmental resistance must be considered to ensure optimal performance.

Testing and Validation of Couplings

Comprehensive testing and validation protocols are crucial to ensure that mechanical couplings meet the stringent requirements of military applications. This includes endurance testing and performance evaluation under simulated operational conditions.

Maintenance of Mechanical Couplings

Regular maintenance is vital for the longevity and reliability of mechanical couplings in military vehicles. This involves periodic inspections, lubrication, and timely replacement of worn components.

Future Trends in Mechanical Coupling

The future of mechanical coupling in military vehicles is likely to be characterized by further advancements in smart materials, integration of IoT for predictive maintenance, and enhanced modular designs for ease of replacement.

Case Study: Coupling Applications in Modern Military Vehicles

Exploring real-world applications of mechanical couplings in modern military vehicles can provide insights into their practical utility and performance under varied operational scenarios.

Environmental Impact Considerations

The manufacturing and disposal of mechanical couplings have environmental implications. Sustainable practices and the use of eco-friendly materials are increasingly becoming a focus in their development.

Comparative Analysis of Coupling Technologies

A comparative analysis of different coupling technologies can help in selecting the most suitable type for specific military applications, balancing performance, cost, and durability.

Conclusion

Mechanical couplings are indispensable components in military vehicles, contributing significantly to their operational efficiency and reliability. Continuous innovation and adherence to rigorous standards will drive future advancements in this critical domain.

How does a mechanical coupling work?

A mechanical coupling works by joining two rotating shafts together to transmit power from one shaft to the other. This connection can accommodate misalignment, absorb shocks, and dampen vibrations, ensuring smooth and efficient power transfer.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling involves considering several parameters and actual conditions:

- Load Capacity: The coupling must be able to handle the maximum load that will be transmitted through it. This ensures durability and prevents failure under heavy loads.

- Misalignment Tolerance: Different couplings have varying capacities to accommodate misalignment between shafts. Assess the degree of misalignment in your system to choose the appropriate coupling.

- Environmental Conditions: Consider the operational environment, including temperature, humidity, and exposure to contaminants. Select couplings made from materials that can withstand these conditions.

- Vibration and Shock Absorption: In applications involving high levels of vibration or shock, choose couplings that can absorb these forces to protect the connected machinery.

- Maintenance Requirements: Evaluate the maintenance needs of the coupling. Some couplings require regular lubrication and inspection, while others are designed for minimal maintenance.

What are the classification of couplings in mechanical engineering?

Couplings in mechanical engineering can be classified into several categories based on their design and application:

- Rigid Couplings: These are used where precise shaft alignment is essential and there is no allowance for misalignment.

- Flexible Couplings: These can accommodate some degree of misalignment and are used to reduce the transmission of shock loads.

- Fluid Couplings: These use hydraulic fluid to transmit power and provide smooth acceleration without mechanical contact.

- Torque-Limiting Couplings: These are designed to slip or disconnect when torque exceeds a predetermined limit, protecting machinery from damage.

- Universal Couplings: Also known as U-joints, these allow for the transmission of motion between shafts that are not in perfect alignment.

HZPT: Leading the Way in Mechanical Couplings

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating research, learning, production, and international trade. We adhere to our core values of integrity and strive for innovation, teamwork, and progress. Our expertise lies in the research and development of coupling products, and our business spans Asia, Europe, Africa, and North America. We are dedicated to becoming a globally influential international group.

Our company specializes in producing a wide range of coupling products, including drum couplings, spring pin couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a comprehensive and scientific quality management system, our own technical development and testing department, and certifications such as CQC, ISO, and CE. We provide excellent sales services and technical support to over a hundred partner companies, embracing a customer-first philosophy to foster collaborative growth.

We recommend our mechanical coupling products for the following reasons:

- High-Quality Materials: Our couplings are made from top-grade materials, ensuring durability and longevity even under extreme conditions.

- Innovative Designs: Our products feature cutting-edge designs that enhance performance and reliability, catering to a wide range of applications.

- Comprehensive Testing: All our couplings undergo rigorous testing to meet international standards, guaranteeing their reliability and efficiency.

- Global Reach: With a strong presence across multiple continents, we provide timely and effective support to our global clientele.

- Customer-Centric Approach: We prioritize our customers’ needs and offer tailored solutions to meet their specific requirements, fostering long-term partnerships.