Mechanical Coupling for Vaccine Production Equipment

Introduction to Mechanical Couplings

Mechanical couplings are indispensable components in vaccine production equipment. They ensure the seamless transfer of power between different machine parts, thus enhancing efficiency and reliability.

The Importance of Couplings in Vaccine Production

In the realm of vaccine production, mechanical couplings are critical for maintaining precise operations. They help in minimizing downtime and ensuring continuous production cycles.

Types of Mechanical Couplings Used in Vaccine Production

Various types of mechanical couplings, including flexible, rigid, and fluid couplings, are employed to cater to different requirements of vaccine production equipment.

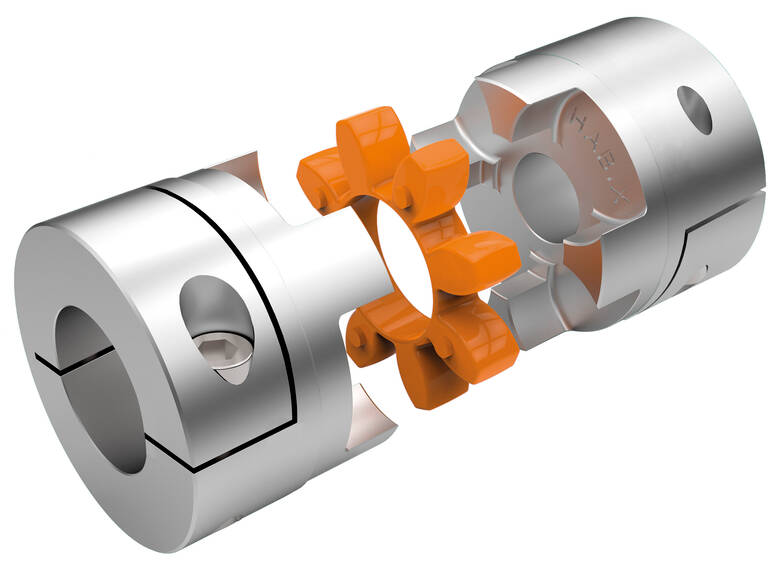

Flexible Couplings: Versatility in Action

Flexible couplings are known for their ability to accommodate misalignment and absorb shock loads. This makes them ideal for delicate operations in vaccine production.

Rigid Couplings: Stability and Strength

Rigid couplings provide a robust connection between two shafts, ensuring rigidity and stability. They are typically used in applications where precise alignment is crucial.

Fluid Couplings: Smooth Power Transmission

Fluid couplings use hydraulic fluid to transmit power. They offer smooth acceleration and deceleration, making them suitable for sensitive vaccine production processes.

Significance of Precision in Coupling Selection

The selection of the right coupling is paramount to achieving precision in vaccine production. Factors like torque, speed, and alignment must be carefully considered.

Challenges in Vaccine Production Coupling

Coupling in vaccine production faces challenges such as high operational speeds, continuous use, and varying operational environments. Proper maintenance and selection are key.

Innovative Materials for Mechanical Couplings

Modern mechanical couplings are made from innovative materials like advanced composites and specialized alloys, which enhance durability and performance.

Maintenance of Mechanical Couplings

Regular maintenance of couplings is crucial for ensuring long-term functionality. This includes periodic inspections, lubrication, and timely replacements.

Technological Advances in Coupling Design

Advancements in technology have led to the development of couplings with enhanced features such as reduced backlash, increased torque capacity, and improved alignment capabilities.

The Role of Couplings in Automated Vaccine Production

In automated vaccine production, mechanical couplings play a vital role in ensuring synchronized operations and reducing mechanical wear.

Case Studies of Couplings in Vaccine Production

Examining case studies where mechanical couplings have been successfully implemented can provide insights into best practices and innovative solutions.

Future Trends in Mechanical Couplings for Vaccine Production

The future of mechanical couplings in vaccine production lies in smart couplings with integrated sensors for real-time monitoring and predictive maintenance.

Conclusion

Mechanical couplings are crucial for the efficient operation of vaccine production equipment. Their proper selection and maintenance can significantly enhance productivity and reliability.

How does a mechanical coupling work?

A mechanical coupling works by connecting two rotating shafts together, allowing for the transfer of torque and rotational motion between the shafts. The coupling aligns the shafts and compensates for any misalignment, ensuring smooth and efficient power transmission.

How do I choose a mechanical coupling?

Choosing the right mechanical coupling involves considering several parameters and actual conditions:

- Torque Requirements: Determine the maximum torque that the coupling needs to transmit. This is crucial to ensure the coupling can handle the operational load without failure.

- Speed: Evaluate the operational speed of the equipment. Different couplings have varying speed capacities, and selecting one that matches your speed requirement is essential.

- Misalignment: Assess the potential misalignment between the shafts. Flexible couplings are suitable for compensating misalignments, while rigid couplings require precise alignment.

- Environmental Conditions: Consider the operating environment, including temperature, humidity, and exposure to chemicals, as these factors can affect the coupling’s material and design choice.

- Space Constraints: Analyze the physical space available for the coupling. Some couplings require more space for installation and operation, and this must be factored into the selection process.

What are the classification of couplings in mechanical engineering?

Mechanical couplings can be classified into several categories:

- Rigid Couplings: These couplings provide a solid connection between two shafts and are used when precise alignment is necessary.

- Flexible Couplings: These couplings can accommodate misalignment and absorb shock and vibration, making them ideal for dynamic applications.

- Fluid Couplings: Utilizing hydraulic fluid, these couplings provide smooth power transmission and are commonly used in sensitive applications.

- Gear Couplings: Consisting of toothed hubs, these couplings transmit high torque and allow for slight misalignment.

- Diaphragm Couplings: Featuring flexible metal diaphragms, these couplings offer high torsional stiffness and compensate for misalignment.

HZPT: A Leading Manufacturer of Mechanical Couplings

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating R&D, production, learning, and foreign trade. Adhering to our core values of “integrity” as our business philosophy, we aim for unity, progress, and innovation. Our company specializes in developing coupling products and serves a global clientele.

Our specialization in manufacturing various coupling products includes drum couplings, spring pin couplings, snake spring couplings, universal couplings, star couplings, expansion couplings, diaphragm couplings, and tire couplings. We have a complete and scientific quality management system, along with our own technology development and testing department. We hold certificates like CQC, ISO, and CE.

We provide excellent sales services and technical support. Serving hundreds of cooperative enterprises, we uphold the business philosophy of “people-oriented, customer first,” collaborating sincerely with customers for mutual development.

Why Choose HZPT for Mechanical Couplings?

- High-Quality Products: Our couplings are manufactured using top-grade materials and advanced technology, ensuring durability and reliable performance.

- Innovative Solutions: We continuously invest in R&D to bring innovative coupling solutions that meet the evolving needs of various industries.

- Global Reach: Our extensive network allows us to serve customers across Asia, Europe, Africa, and North America, providing consistent quality and service.

- Comprehensive Support: We offer detailed technical support and customer service to help clients choose the right couplings and ensure optimal performance.

- Certified Excellence: With certifications like CQC, ISO, and CE, our products meet international standards, giving customers confidence in their quality and safety.